We meet our first return order in October 2019, a returning box machine means we will lose tens of thousands of dollars of working capital, it significantly increases the risk of our company.

1. The quick deal

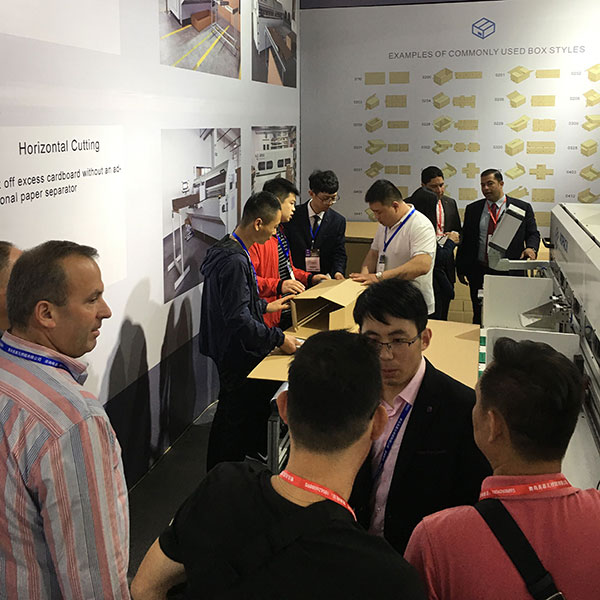

We got to know Mr.Shi at the SinoCorrugated 2019, he was looking for a packing machine to solve his beverage packaging problem. After watching our equipment demonstration at the exhibition, Mr.Shi quickly placed an order for a our BM2508-plus. This customer should be one of our fastest customers. Our communication is no more than 30 sentences before and after.

2. Equipment installation

Everything is ok until the equipment installation, when we teach the people how to use the machine, the production manager said that our equipment is probably useless for their factory. The customer’s factory is very famous in the local, their orders are very large. You can see their scale in the below picture.

Their orders can range from thousands to tens of thousands pieces, and even hundreds of thousands pieces. Our box making machine was installed in the die-cutting workshop, the efficiency of a die-cutting machine is 3000 to 5000 boxes per hour.

However, our equipment is mainly used for making large-size and small quantity orders. If we use our machine to make big order, the efficiency is obviously low. The fact made us worried about the installation.

As expected, the production manager was not satisfied with the capacity of the device after he know the function and performance.

3. Return of the risk

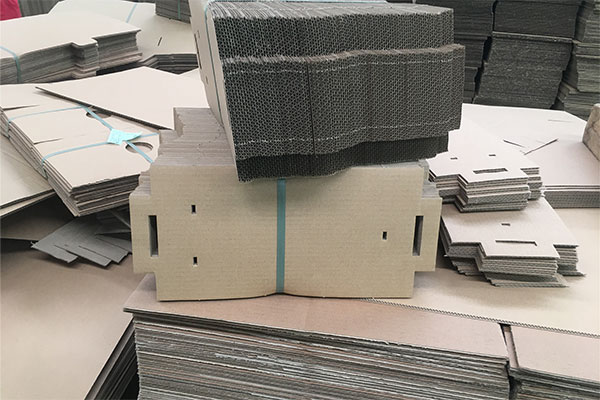

Compared with die-cutting machine, our small batch carton box machine has no advantage for large orders. We explained the product situation to the production manager and told him some boxes that suitable for our machine. Then the production manager arranged some other orders to test, it made us depressed when we see the boxes, because these boxes are only suitable for die-cutting machine. You can see the boxes in the following picture:

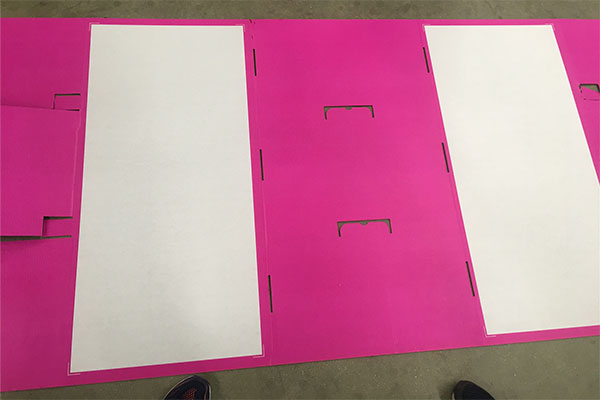

Those carton boxes can’t be processed by ordinary machine, it can only be mass produced by die-cutting, because the molds are required, as shown in the figure below:

As can be seen from the picture above, every order requires a wooden knife mold. If there are many orders, then many molds are required. This is just one corner of the mold library.

4. Turn of events

We have communicated with the production manager according to the facts, and promised that if it is really not suitable for your order, we can handle the return procedure for you now.

The production manager was very shocked, because this machine are specially customized for their company, returns are generally not supported for this machine. he said you are really the most honest supplier I have ever met. Then he said he would let his boss make a decision.

A day later, Mr.Shi came to know the situation and assured me that he would not return the goods. He knew the performance of the equipment and the appropriate order type. He bought this equipment to make the boxes that die-cutting machine can’t do, not do the same work as the die-cutting machine. You can training our person with no worry.

5. Delivery

The later installation training is smooth, the production department also arranged some appropriate order to test the machine. When we can easily make an order like a picture, the production manager, he gave us a thumbs up.

6. Summary

We will be responsible for every customer, if you have any questions, we are all priority to solve your problems without worry about the cost, even if it is to return and causes huge losses to the company.

Leave A Comment