Carton Box Making Machine BM2508-Plus

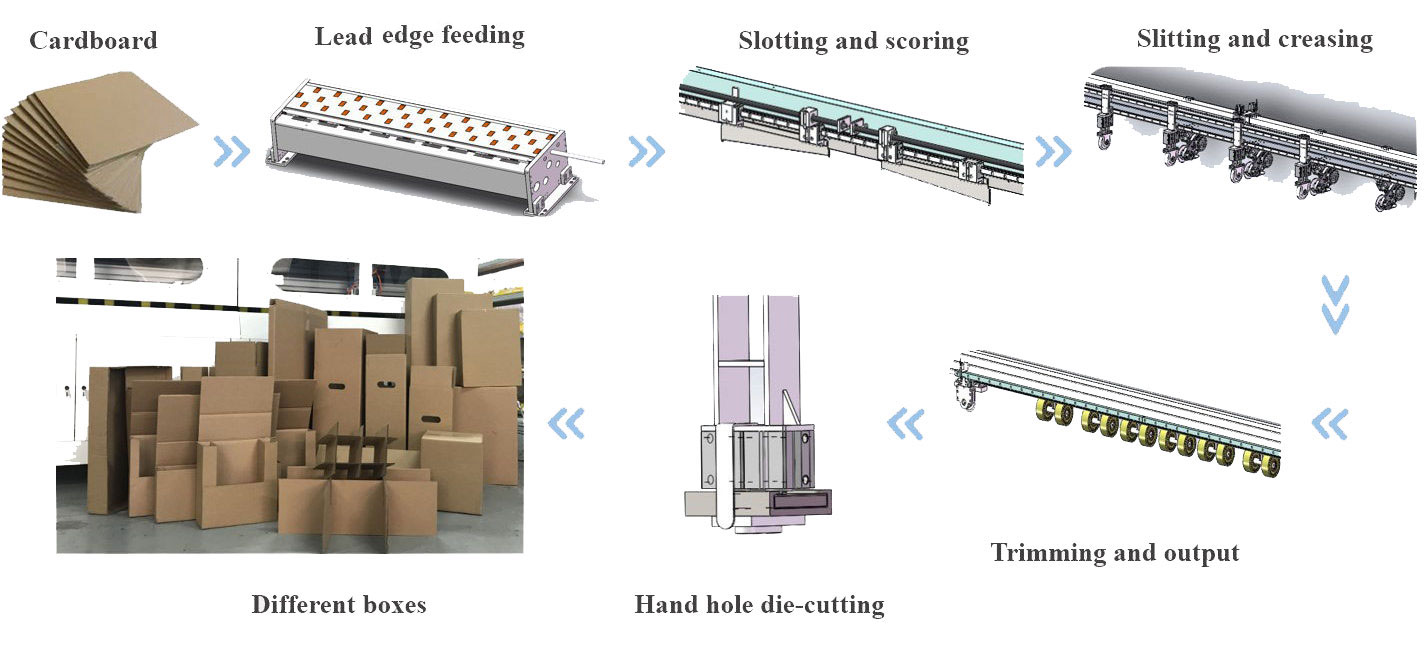

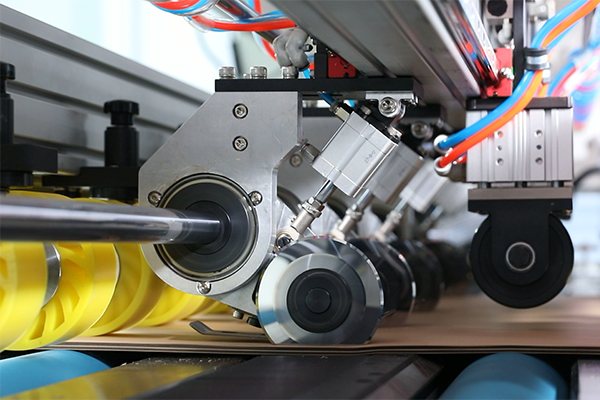

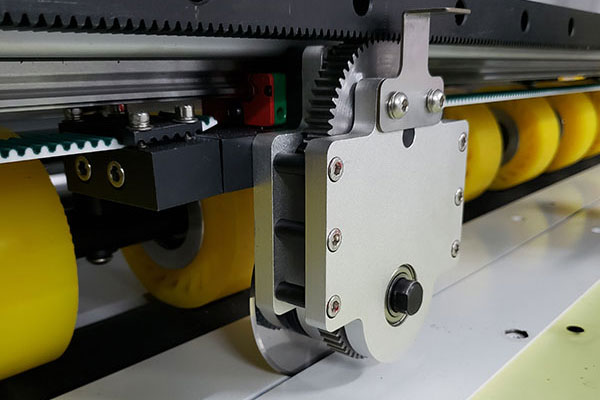

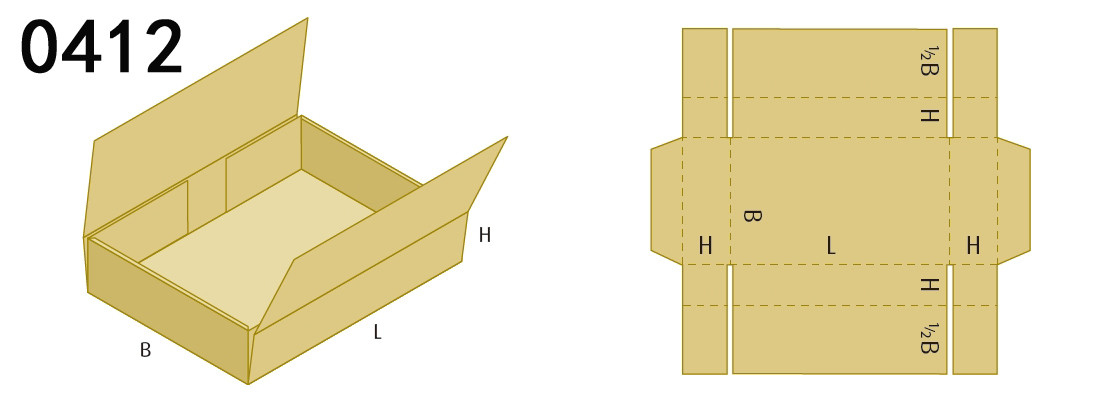

BM2508-Plus carton box machine is a multifunctional packaging machine with horizontal slotting and scoring, vertical slitting and creasing, horizontal trimming.

Compared with traditional packaging equipment, it has a flexible dimension adjusting system. All settings can be entered directly through a touch screen panel within one minute.

Carton Box Machine Application

BM2508-Plus is a fully automatic carton box making machine, suitable for box plants with small quantity orders and big-size cartons, which effectively solves the problem of scattered orders.

It can also provide on-demand corrugated packaging solutions for box factories, furniture, hardware accessories, e-commerce logistics, and other industries. Customized packaging solutions can be designed and provided according to customers’ special requirements.

Standard Configuration

- 1 pcs paper feeding bracket

- 2 pcs 500mm slotting knife

- 1 pcs horizontal scoring beam

- 4 pcs vertical creasing wheels

- 4 pcs vertical slitting knives

- 1 pcs cross cutting knife

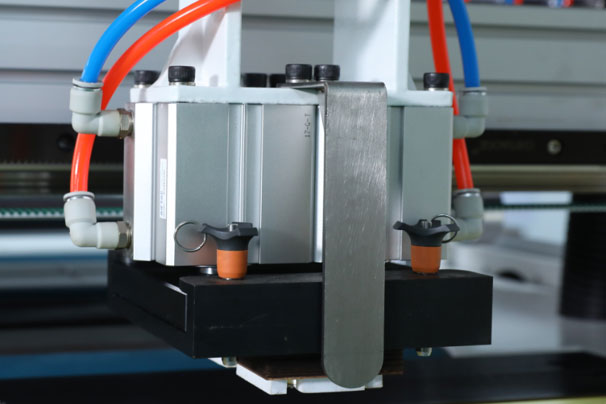

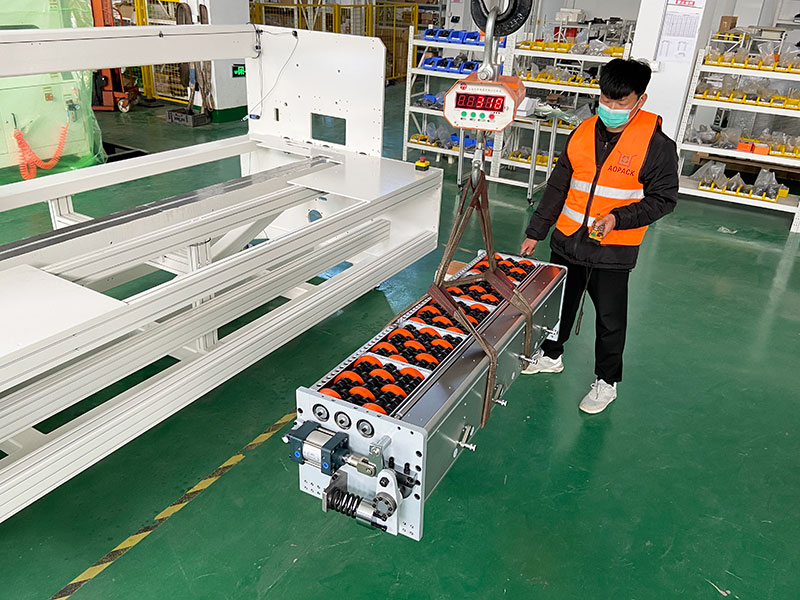

- 1 pcs handle die-cutting module

Carton Box Making Machine BM2508-Plus Specification

| Function | BM2508 Plus | BM2508 SE | BM3000 |

| Corrugated board type | Sheets Or Fanfold (Single, Double wall) | Sheets (Single, Double wall) | Sheets Or Fanfold (Single, Double wall) |

| Cardboard thickness | 2-10mm | 2-10mm | 2-10mm |

| Cardboard density range | Up to 1200g/m² | Up to 1200g/m² | Up to 1200g/m² |

| Max. board size | 2500mm width x unlimited length | 2500mm width x unlimited length | 3000mm width x unlimited length |

| Min. board size | 200mm width x 650mm length | 200mm width x 650mm length | 300mm width x 650mm length |

| Production Capacity | Appr.7-10 pcs/minute | Appr.7-10 pcs/minute | Appr.8-12 pcs/minute |

| Depends on size and box style. | Depends on size and box style. | Depends on size and box style. | |

| Slotting Knife | 2 pcs *500mm Length | 2 pcs *500mm Length | 2 pcs *500mm Length |

| Vertical Cutting knife | 4 | 4 | 4 |

| Scoring/Creasing wheel | 4 | 2 (Option 4) | 4 |

| Horizontal Cutting knife | 1 | 1 | 1 |

| Power supply | BM2508-Plus 380V±10%,Max. 7kW, 50/60 Hz | BM2508-SE 380V±10%, Max. 6.2kW, 50/60 Hz | BM3000 380V±10%, Max. 7.7kW, 50/60 Hz |

| Air Pressure | 0.6-0.7MPa | 0.6-0.7MPa | 0.6-0.7MPa |

| Dimension | 3540(W) * 2050(L)* 2090mm(H) | 3370(W) * 1800(L)* 2000mm(H) | 3650(W) * 1950(L)* 2090mm(H) |

| Gross Weight | Appr.3300Kg | Appr.2800Kg | Appr.3500Kg |

| Automatic paper feeding | Lead edge feeder 1400mm | Lead edge feeder 900mm | Lead edge feeder 1400mm |

| Handhole on box sides | Hand hole module size (120*120mm) | NO | Hand hole module size (120*120mm) |

| Air Consumption | 75L/Min | 40L/Min | 75L/Min |

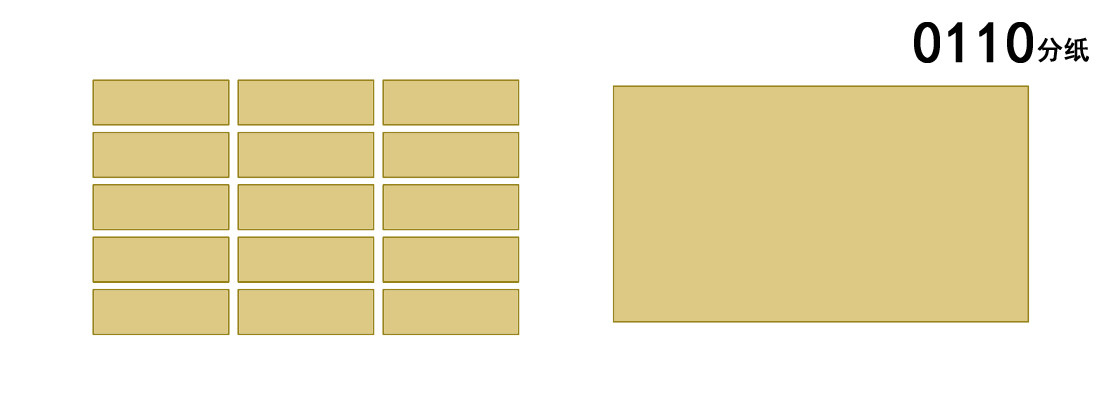

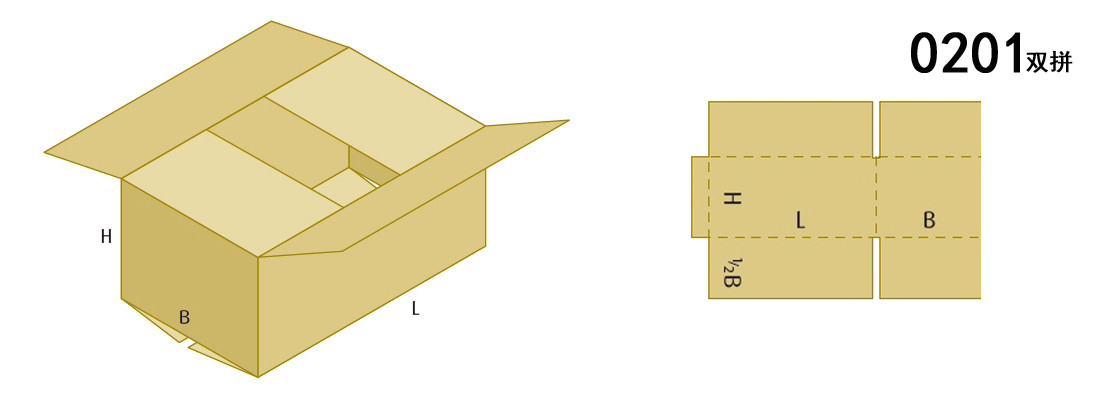

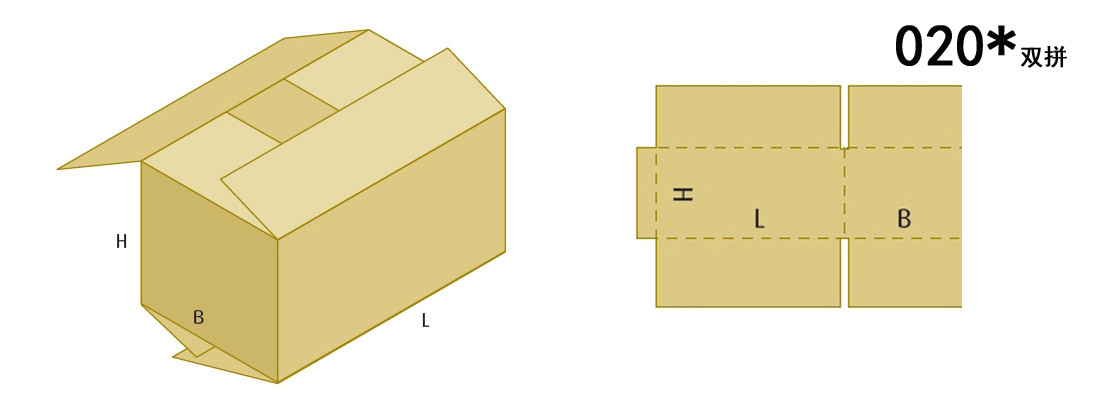

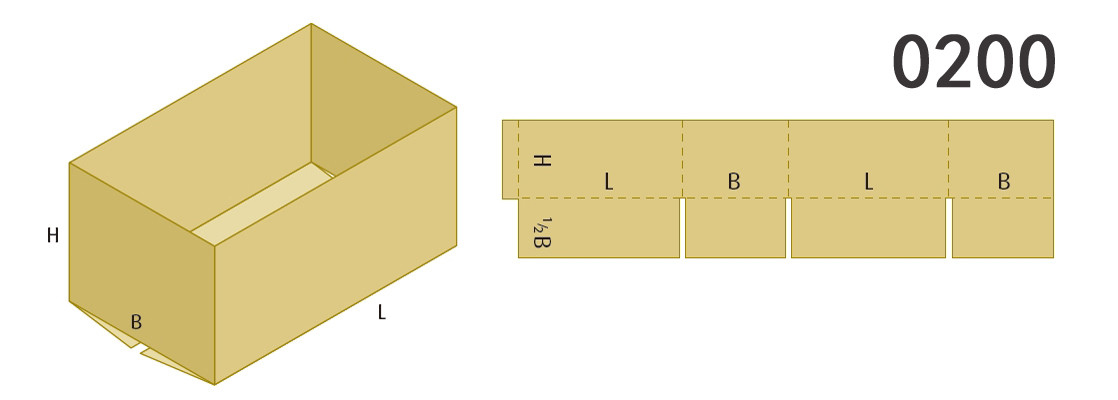

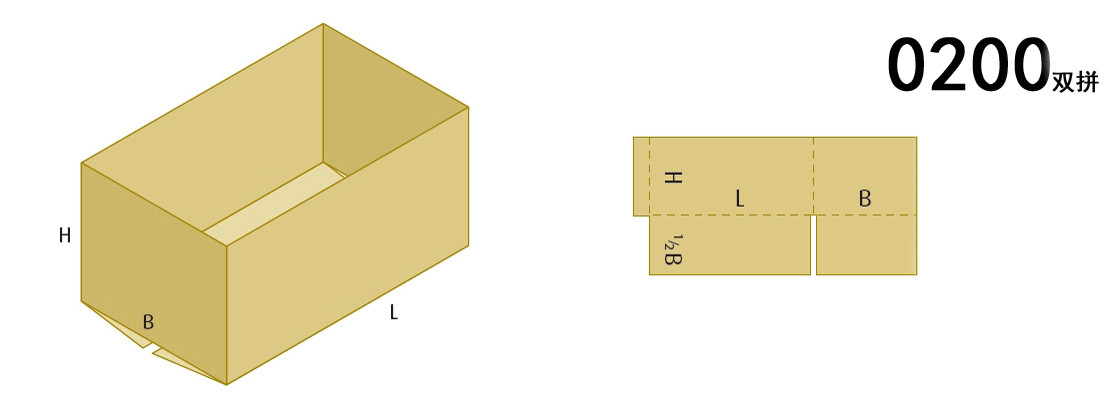

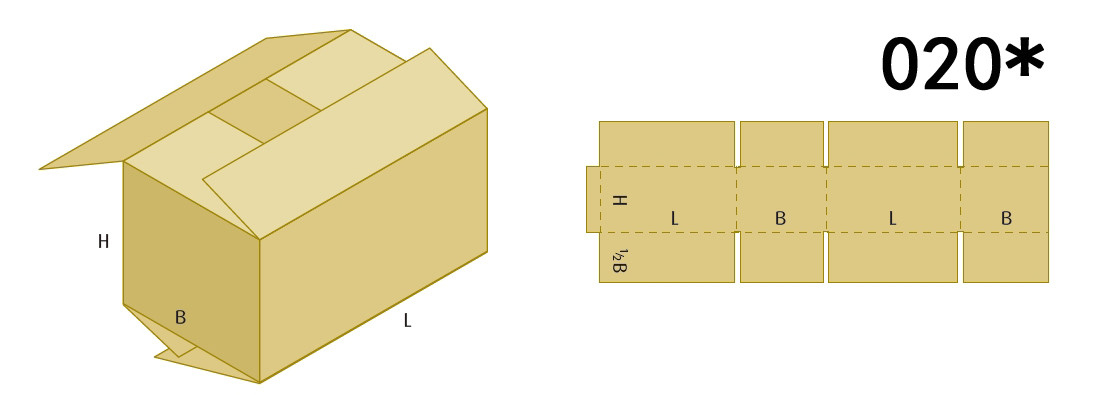

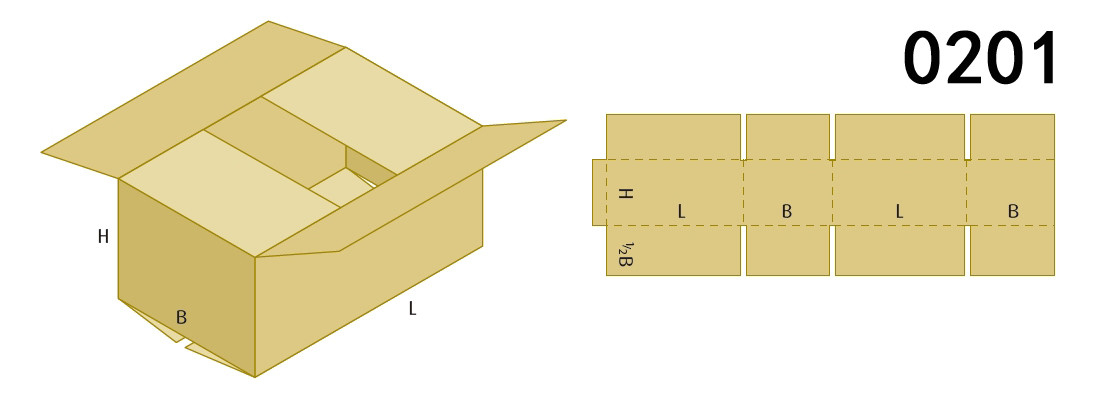

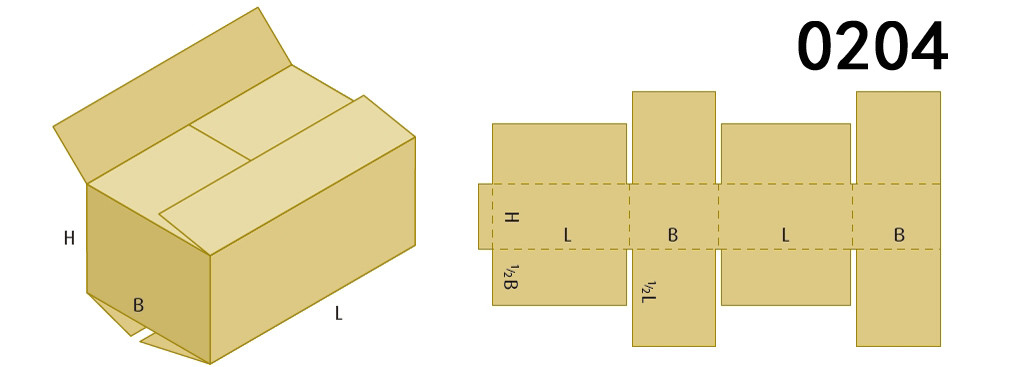

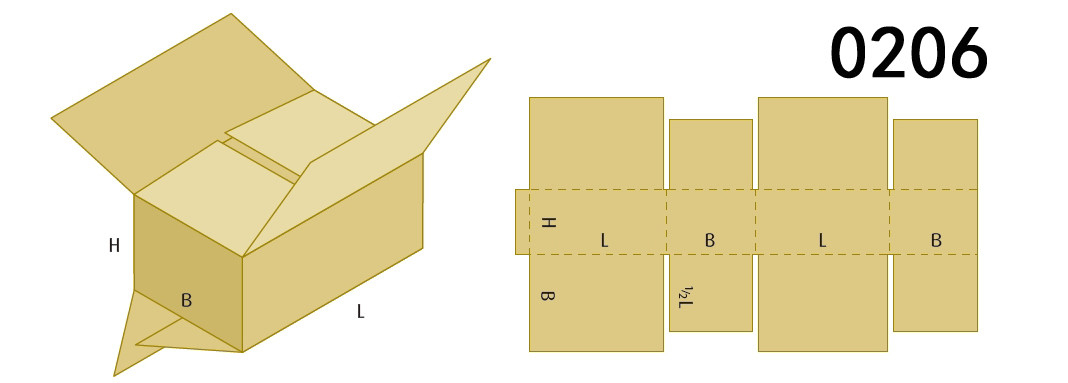

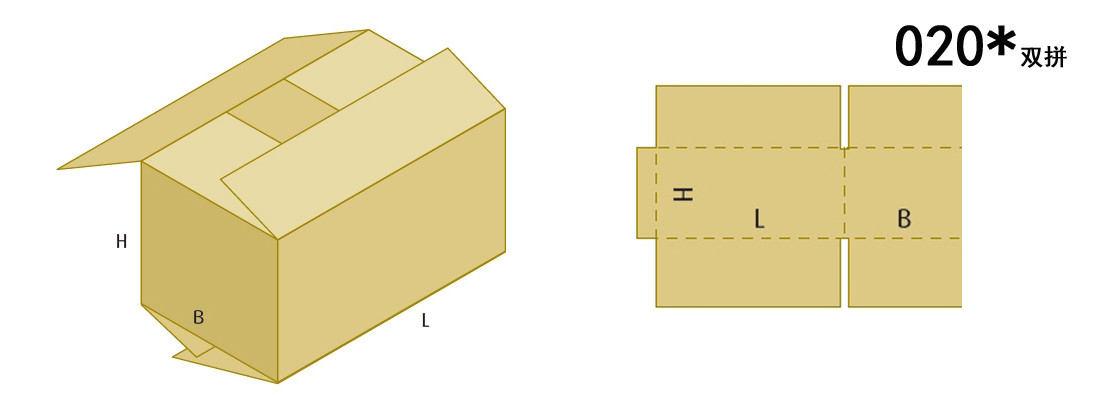

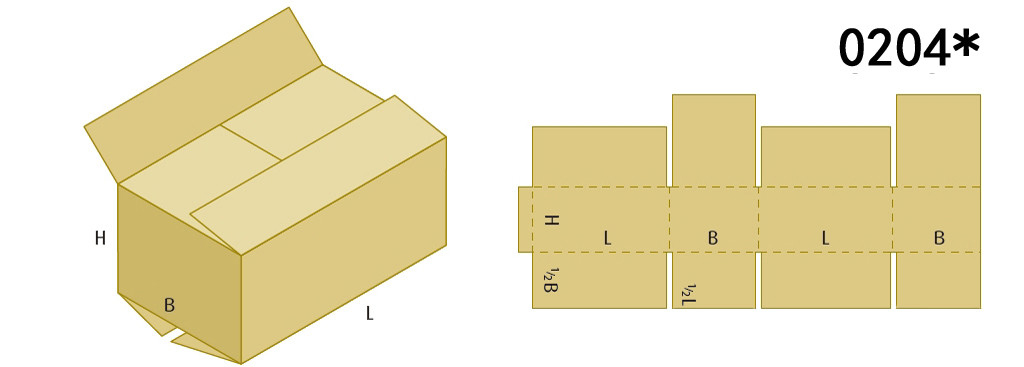

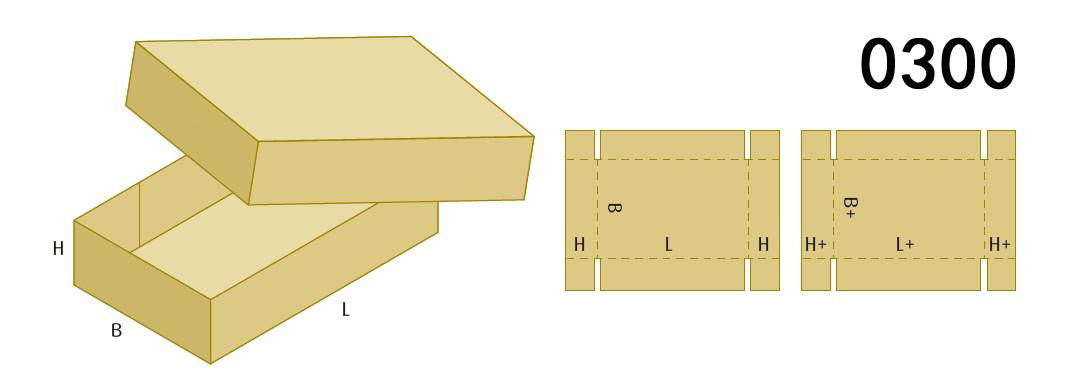

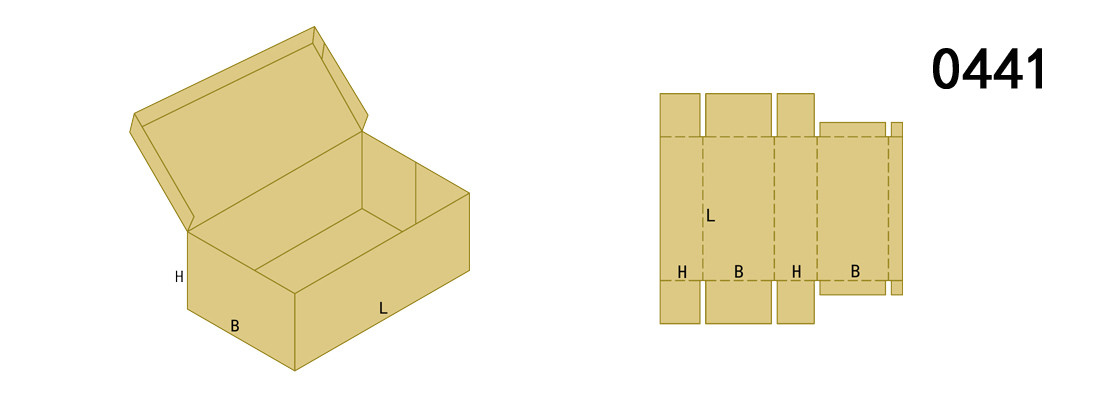

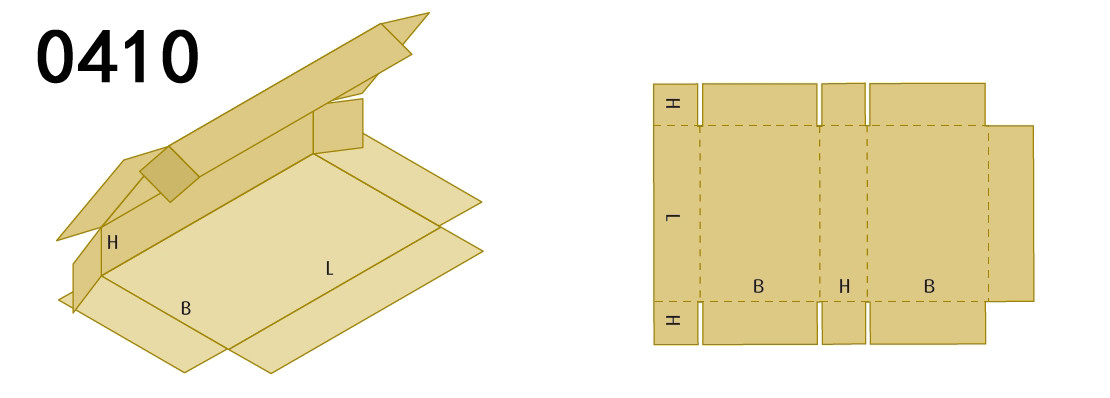

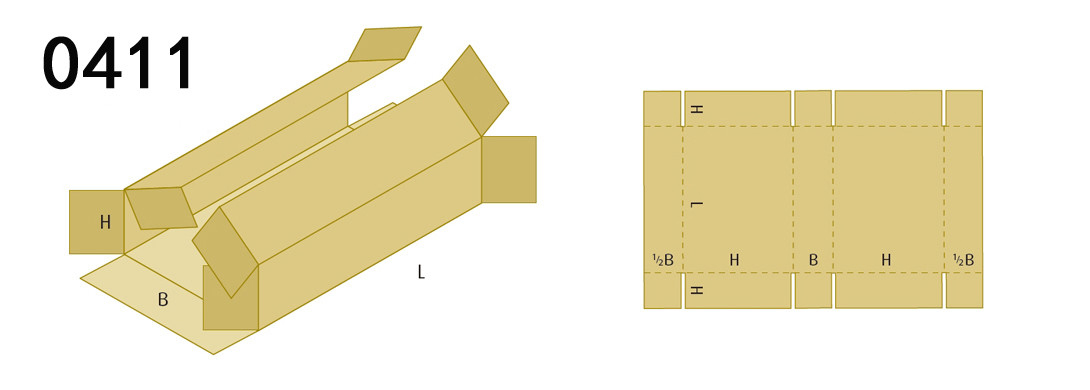

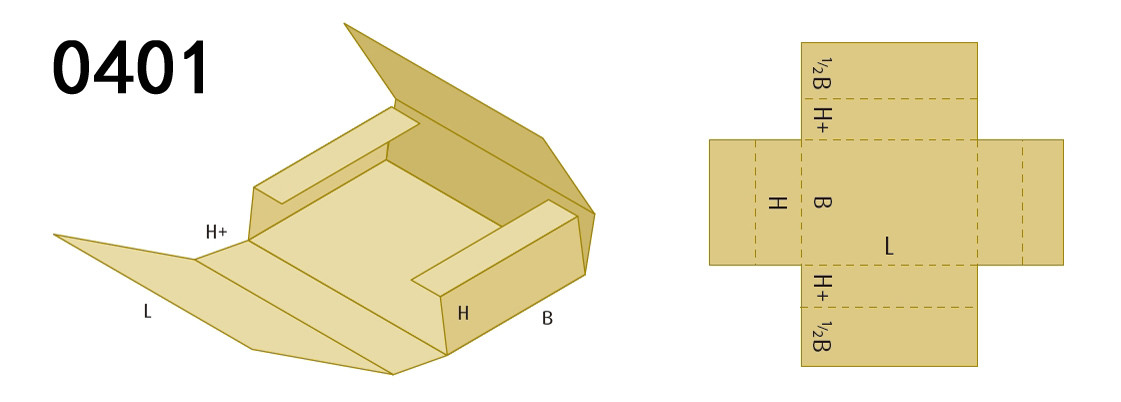

| Box styles | More than 60 Fefco codes | About 27 (36)Fefco codes | More than 60 Fefco codes |

| All the above specifications are for reference only. | |||

| The final interpretation right belongs to Qingdao Aopack On Demand Packaging co., Ltd. | |||

Major Functions Of Carton Box Machine BM2508 Plus

Carton Box Making Machine BM2508 Plus Workflow