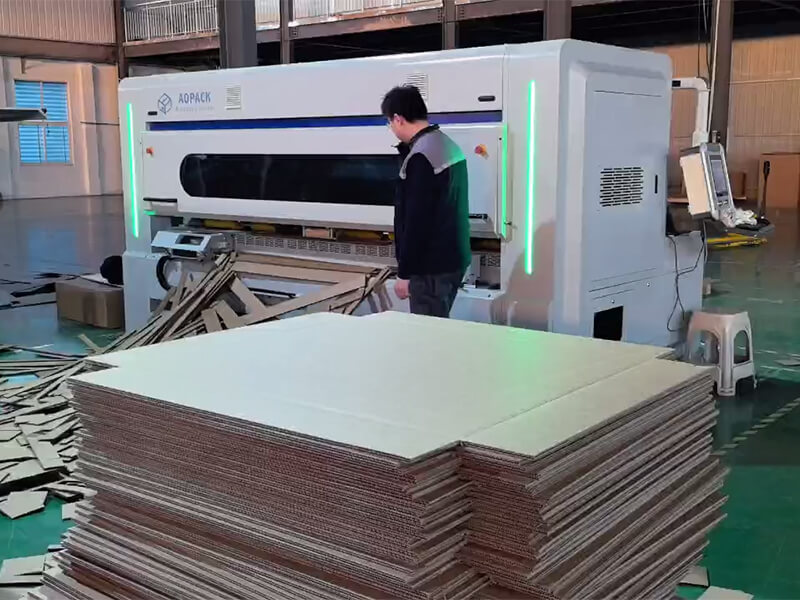

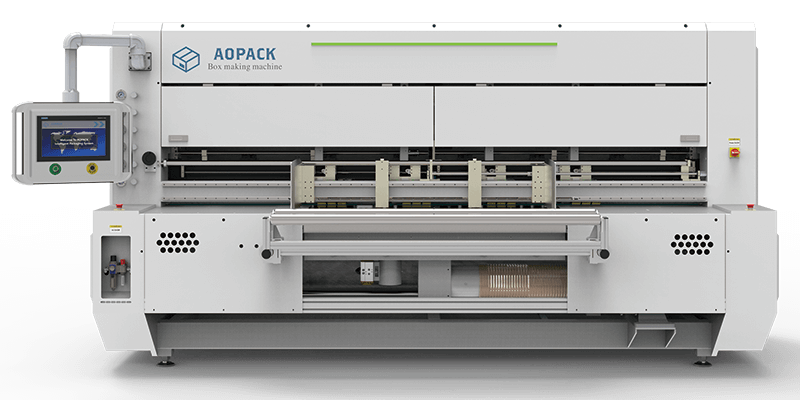

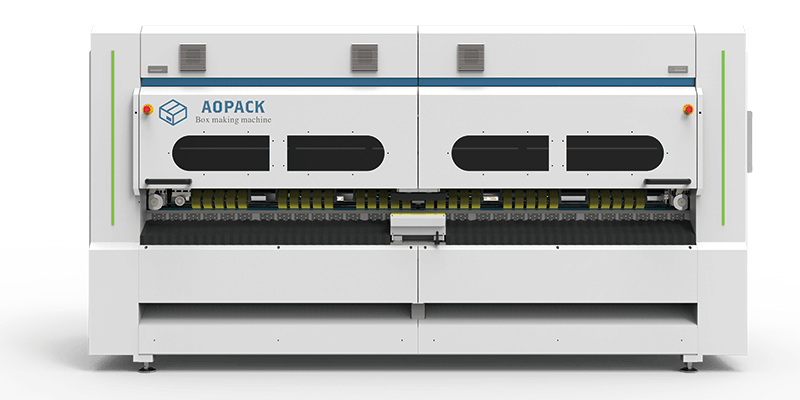

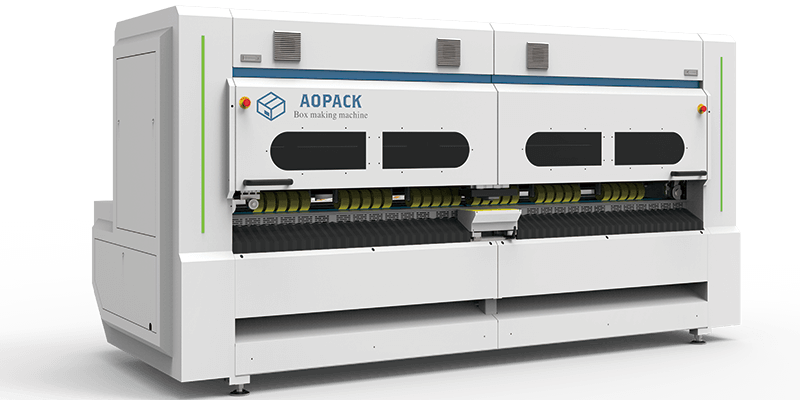

Heavy Duty Box Maker Machine BM3000-HD

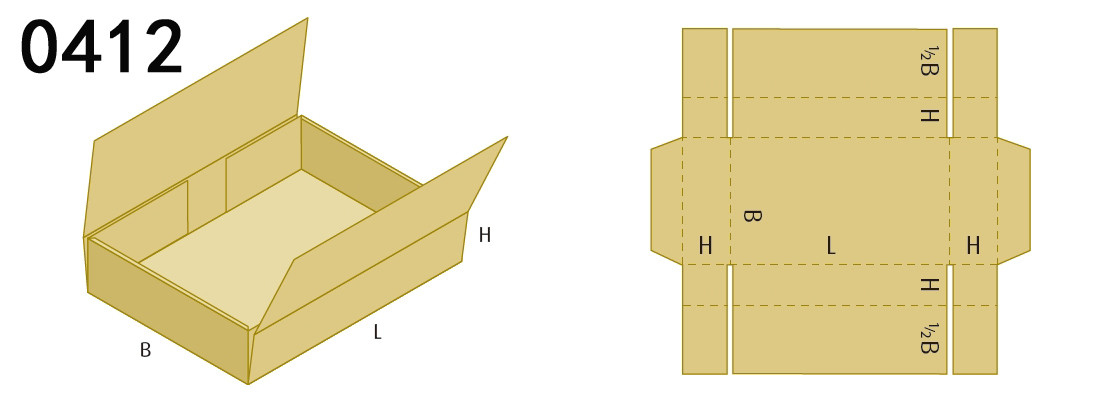

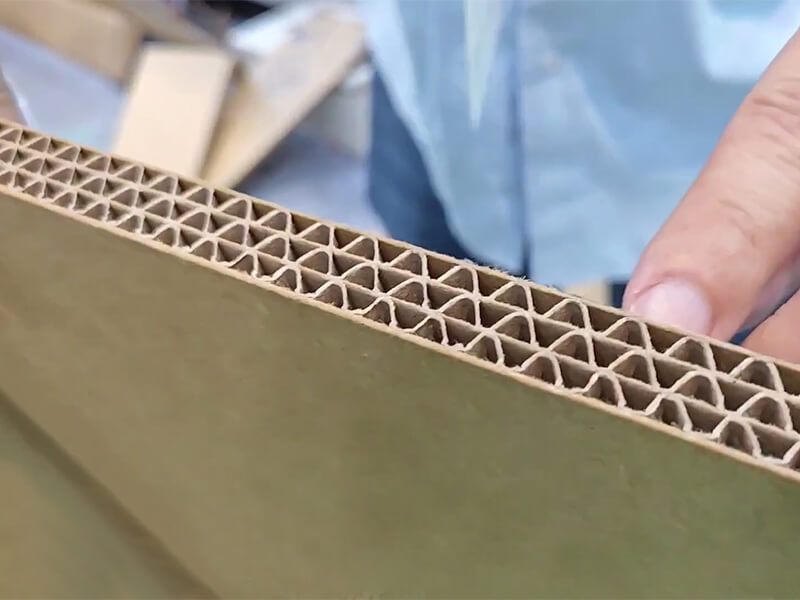

BM3000-HD is a fully automatic slitting, creasing, slotting, and gluing, all in one compact machine. Specialized in low to medium volume heavy duty box production. It can process sheets from E flute to AAA flute. Slotting width from 7mm to 15mm, Excellent cutting performance without any burrs.

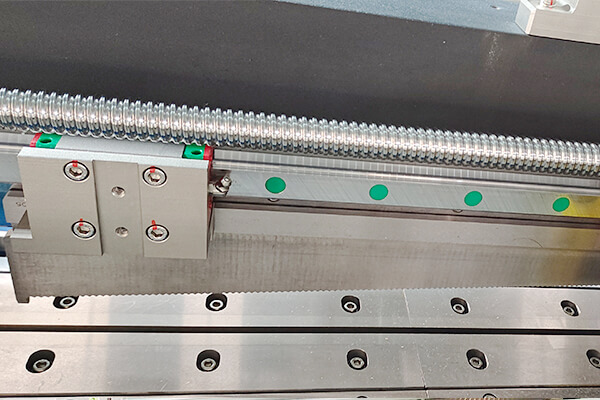

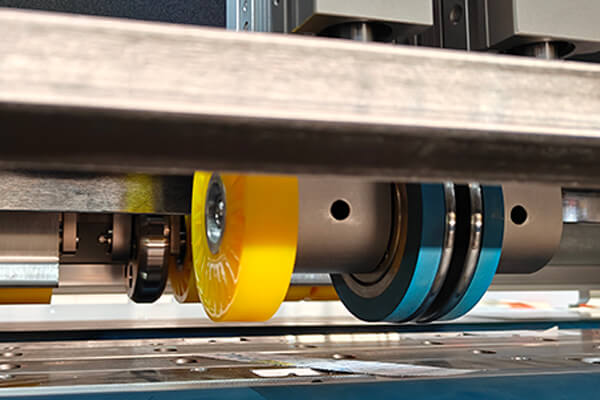

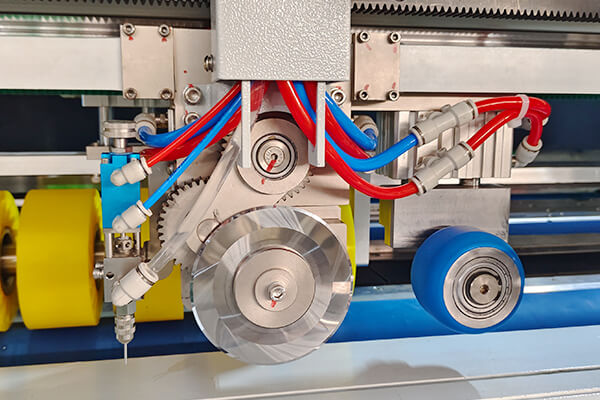

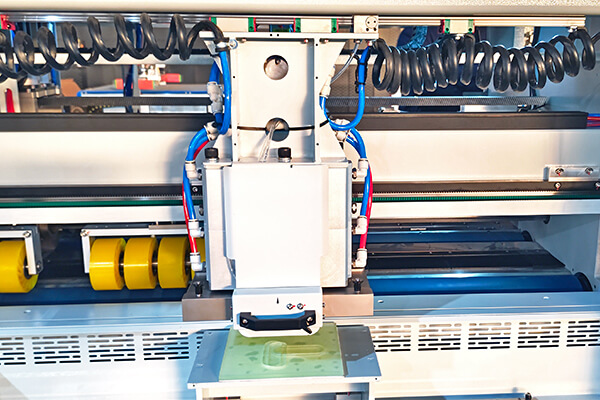

BM3000-HD Product Images

Heavy Duty Box Maker Machine BM3000-HD Specification

| Model | BM3000 HD |

| Corrugated Board Type | Sheets (Single , Double,Triple wall) |

| Cardboard Thickness | 2-16mm |

| Cardboard Density Range | Up to 2400g/m² |

| Max.board Size | 3000mm width x unlimited length |

| Min.board Size | 300mm width x 650mm length |

| Production Capacity | Appr.10-16 pcs/minute |

| Depends on size and box style. | |

| Slotting Knife | 2 pcs *500mm Length |

| Vertical Slitting Knife | 4 |

| Vertical Creasing Wheel | 4+4 |

| Cross Cutting Knife | 1 |

| Power Supply | 380V±10%,Max. 10kW, 50/60 Hz |

| Air Pressure | 0.6-0.7MPa |

| Dimension | 3820(W) * 2060(L)* 1970mm(H) |

| Gross Weight | Appr.4500Kg |

| Handhole on Box Sides | Hand hole module size (150*300mm) |

| Glue Flap Crash | √ |

| Air Consumption | 90L/Min |

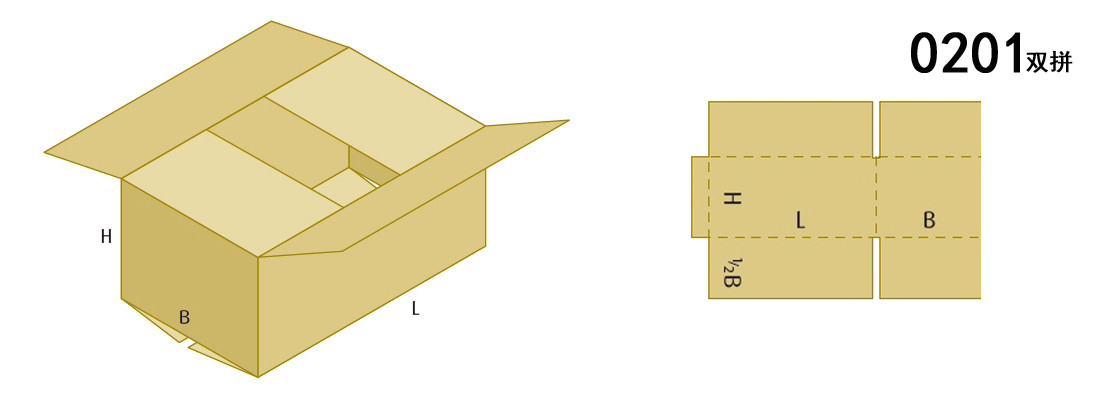

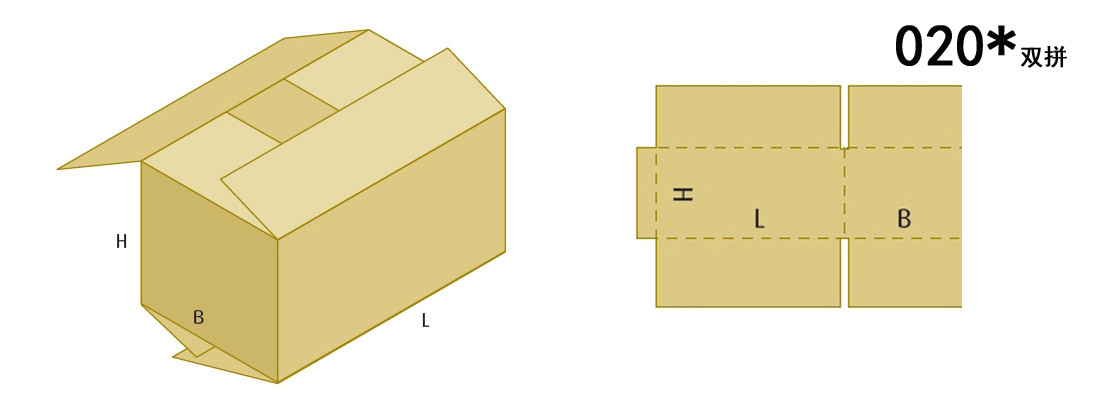

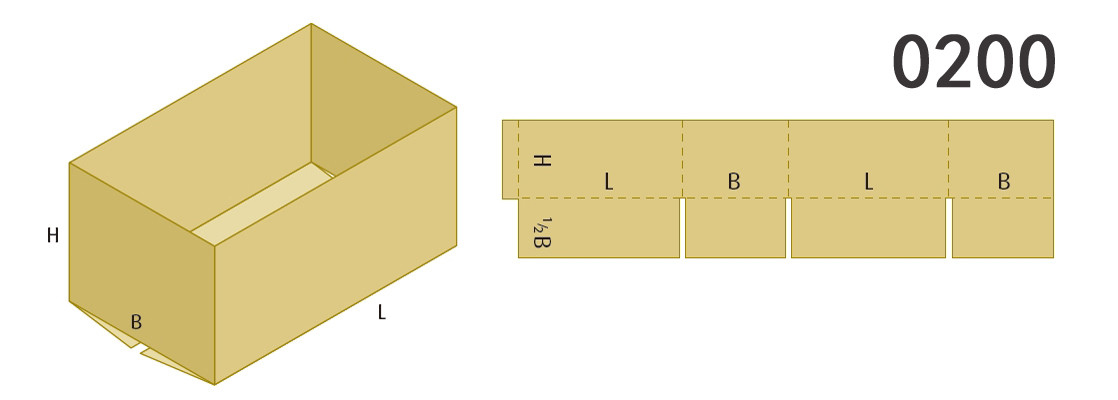

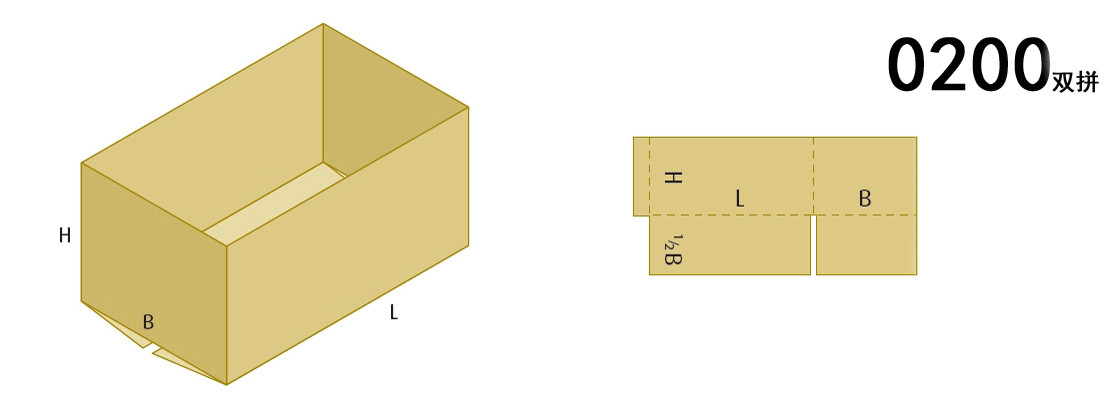

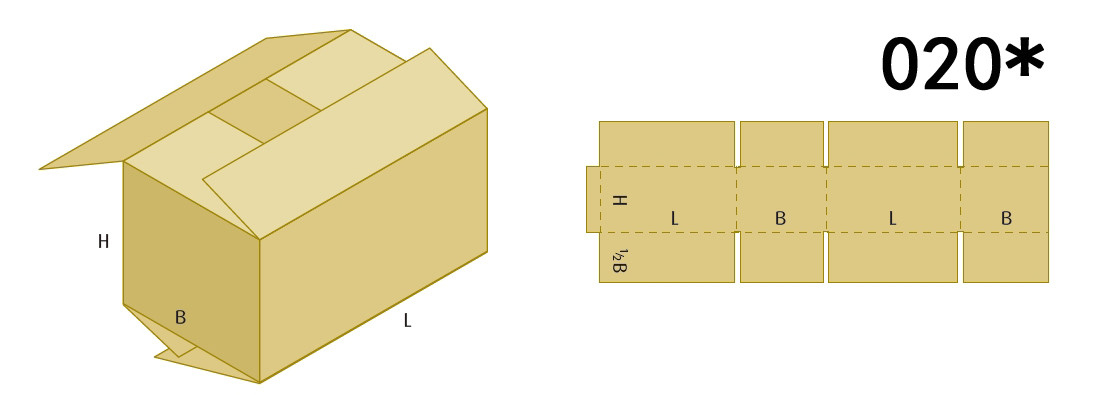

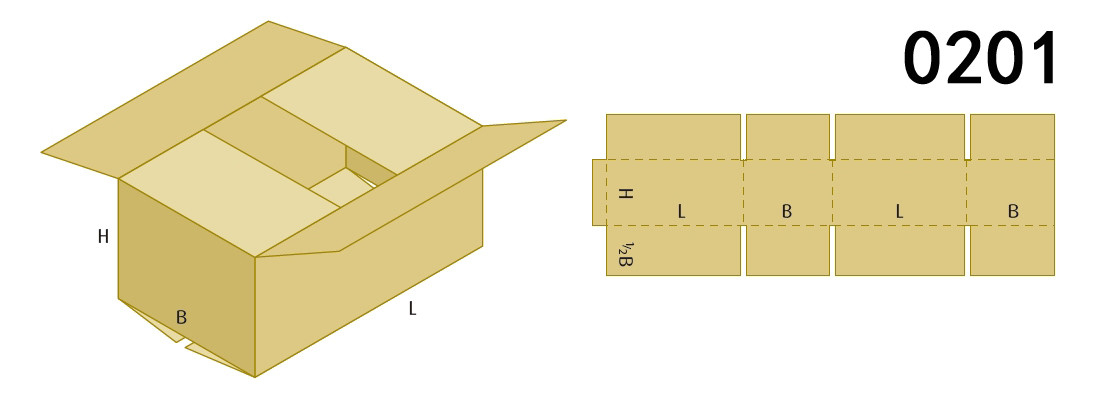

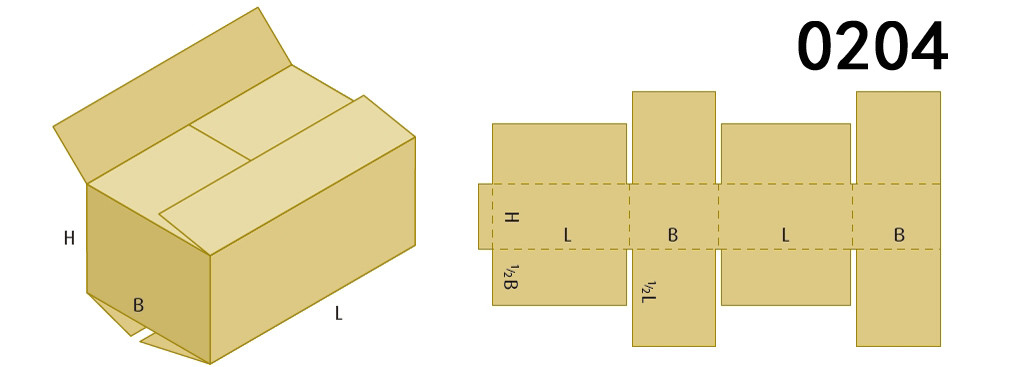

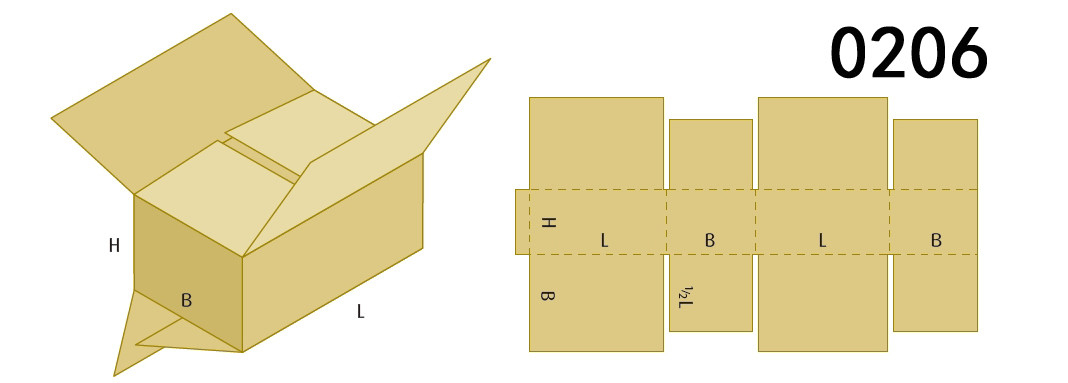

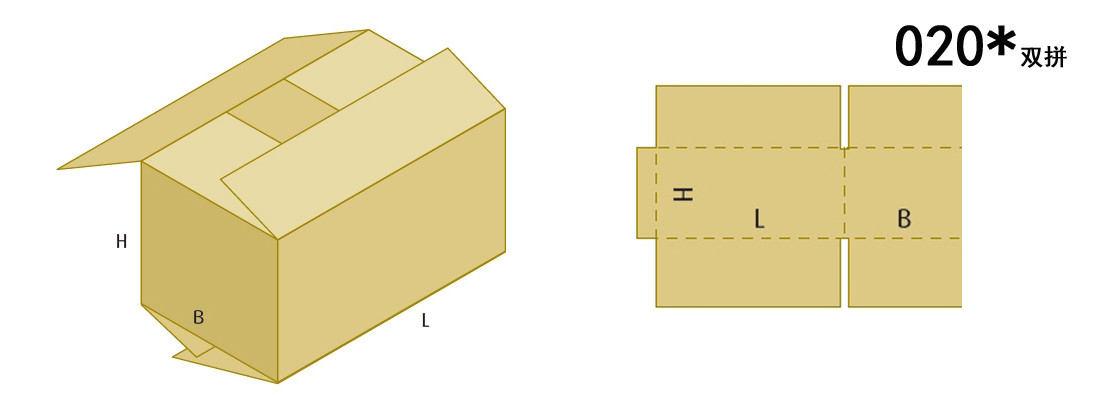

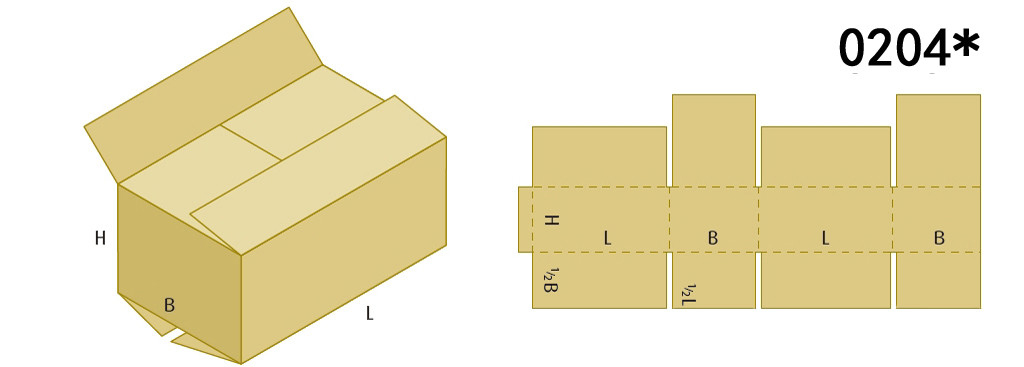

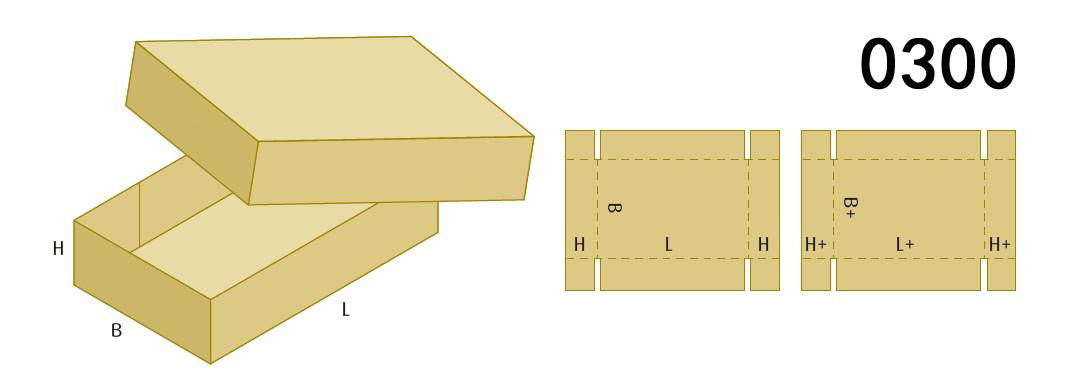

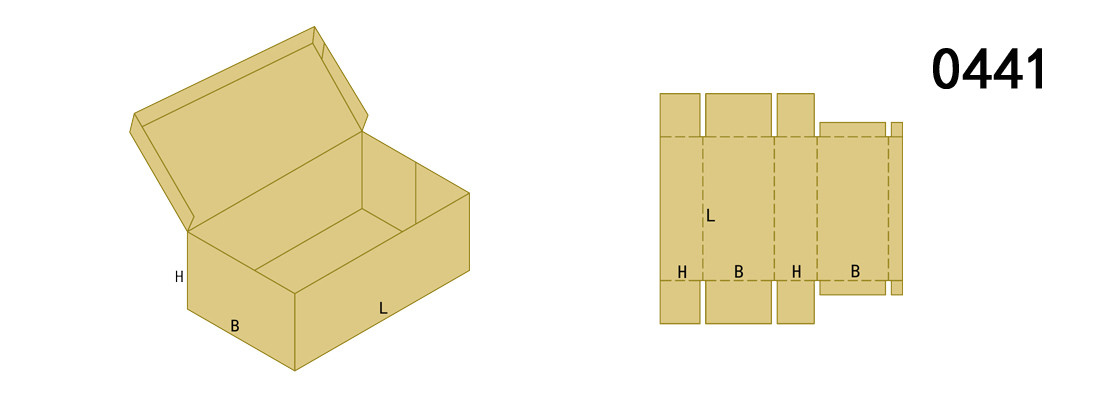

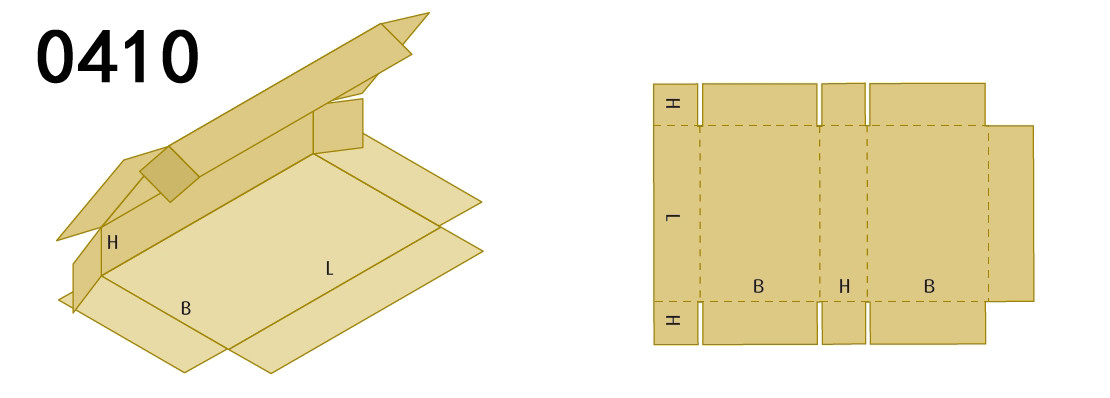

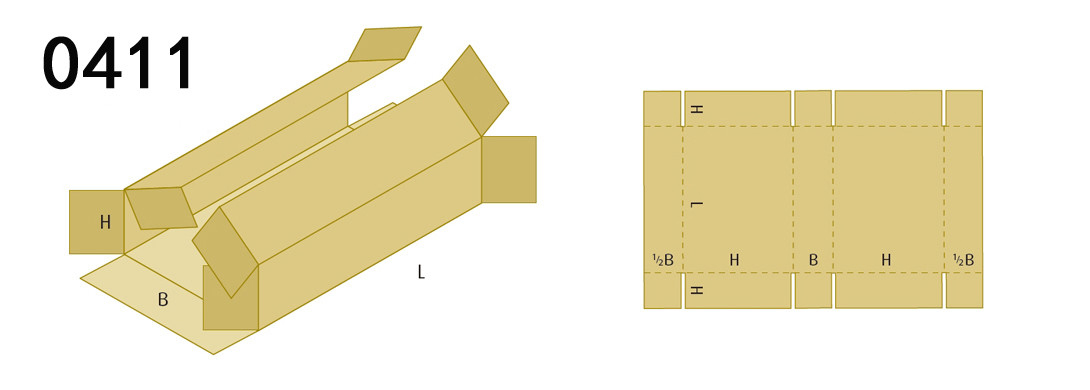

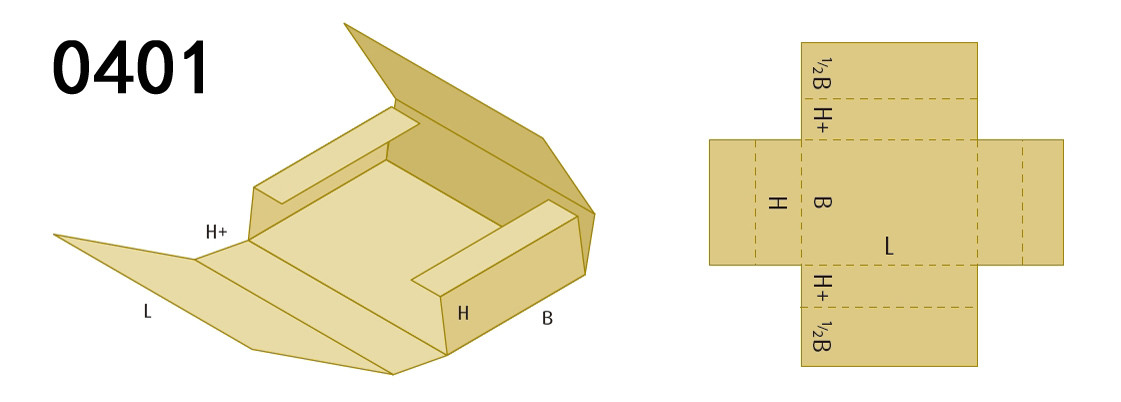

| Box Styles | More than 80 Fefco codes |

| All the above specifications are for reference only. The final interpretation right belongs to Qingdao Aopack On Demand Packaging co., Ltd. |

|