Welcome to this guide, the definitive guide to corrugated board, read on to learn more.

1. Who invented corrugated cardboard?

Corrugated cardboard boxes were first invented in 1890 by Scottish-born Robert Gair. Gail discovered it by accident while making paper bags. He discovered that by cutting and creasing the cardboard he used in one operation, he could make prefabricated boxes.

Since then, corrugated cardboard boxes have become a form of packaging, if not the most popular. They are everywhere, from pizza boxes to cardboard postal boxes for online deliveries to the cardboard knockdown boxes we use when moving.

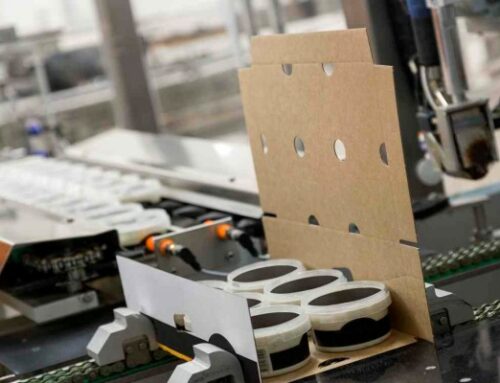

2. How is corrugated cardboard made?

Corrugated cardboard is made from a variety of papers, and the strength of the cardboard depends largely on the material used. Liner and corrugated paper make up a standard sheet of corrugated cardboard. The corrugated paper is sandwiched between the outer and inner linings and then starched to the flat backing paper.

3. Why is corrugated cardboard used for packaging?

According to Amazon, 1.5 billion cardboard packages will be delivered by 2020, making corrugated cardboard the most popular form of packaging for e-commerce. So what are the advantages of corrugated cardboard that make it the first choice for packaging?

1) Corrugated cardboard is light in weight

Corrugated cardboard is lightweight, and rigid and can provide proper protection through shock absorption and temperature protection, which is why people are considering using corrugated cardboard in packaging materials.

2) Corrugated cardboard provides great protection

Cardboard is very effective for protecting fragile and non-breakable items. Sheets of paper are glued to the corrugated interior of the sheet to provide extra strength to the box structure to support heavy loads and resist shocks, shocks, drops, and vibrations. The protective corrugated layer in the paperboard also provides excellent insulation and helps keep the product from getting wet.

3) Corrugated cardboard can be customized easily

Corrugated packaging can increase your brand awareness and serve as a new channel for marketing your products. Adding printed artwork to the surface of the cardboard can significantly increase brand awareness and really communicate your message and brand values effectively.

4) Corrugated cardboard is suitable for environmentally friendly packaging

Corrugated cardboard is environmentally friendly packaging that is easy to dispose of. Over 80% of corrugated packaging and cartons are recycled in the UK, a higher percentage than any other major packaging material. At Boxed-Up, our cardboard waste is recycled using the recycling model. Reduce, reuse and recycle are at the heart of every stage of our manufacturing process, meaning our cardboard offcuts and scraps are used again and again in our products while still maintaining durability! This efficient recycling enables a renewable resource – paper fiber – to be used again as part of a closed-loop recycling process for corrugated packaging.

5) Corrugated cardboard is elastic

Cardboard is a flexible material, especially corrugated, known for its high quality and innovative construction. Paperboard provides an economical and practical way to protect products, stabilize loads and box irregularly shaped goods. Thanks to its flexibility, boxes can be manufactured in various sizes and styles, providing single or double wall protection for your products.

4. Corrugated cardboard characteristics

When searching for corrugated board, you will often see the board described as B125KT, which is an abbreviated description of the board grade, sheet weight and flute size.

B = slot size

125 = paperweight

KT = kraft paper/test paper (Outer/Inner Liner)

To understand this further, we’ll examine what this means.

Corrugated cardboard is made in three parts, including a “fluted” or “wavy” middle section and two paper or card outer liners, which are then glued to the grooves to increase the stability of the board and form a strong structure. The backing paper is made of kraft paper or test paper.

Vellum or test paper – Vellum is a popular choice when making boxes and has a smoother finish, making it ideal for printing. The test uses recycled paper, which is not as good-looking as kraft paper, and is often used inside the box.

There are other types of paper such as clay-coated and bleached, but these are more specialty papers and are not widely used in e-commerce.

Paper Weight – Paperweight is measured in grams per square meter or GSM. Common weights for boxed use are 125 gsm, 150 gsm and 200 gsm.

Corrugated Board – Various types of board can be manufactured using different flute sizes, including double-wall, single-wall and triple-wall. Single-walled consists of two sheets and a middle fluted section, double-walled has an extra lining and fluted, and triple-walled adds another layer of fluted and extra lining.

The grooves can vary in width and size, and the arched shape of the grooves allows air to circulate, acts as an insulator, and provides additional protection against temperature changes. Flute can affect the performance of your box.

- E Flute is used in our die-cut tube boxes, such as our C4 and C5, and smaller cartons, such as our daughter boxes. This type of corrugated paper is ideal for printing due to its high-quality surface, excellent compressive strength and excellent resistance to crushing.

- B Flute is the ideal corrugated paper for shipping packaging. It’s thicker and heavier. This is the flute Boxed-Up uses to make, and it’s a nice all-rounder.

- BC Flute – B Flute is combined with C Flute to provide an even higher level of protection for your product. Boxed-Up uses this grooved profile on all of our double wall boxes, including our moving boxes.

- Z Flute – Also known as the M, S or R Flute®. Due to its high quality surface, it is ideal for printing. This is a smaller, more compact groove while also optimizing the cardboard strength. It is perfect for eCommerce and online sellers and provides the necessary protection for your products.

The benefits of Z-flute are as follows:

- Save more for customers

- neat box

- 20% increase in storage and delivery

- more trays**

- 100% recyclable

- Higher crush resistance than B flute

- Can withstand the rigors of transportation

- Ideal for eCommerce

- reduce carbon footprint

- improve performance

- Does not affect the integrity of the box

- Ideal for FMCG

Leave A Comment