In order for a business to be successful, it is important to get a good return on investment (ROI). Automatic packaging machines can help improve your company’s return on investment in a number of ways. Return on investment is usually defined as the percentage of profits a company earns as a percentage of its total investment. To improve ROI, businesses need to find ways to reduce costs and increase revenue.

Automating the packaging process can help reduce costs in several ways. For example, automated machines can pack products faster than humans, reducing labor costs. In addition, automated packaging machines can usually handle more delicate products without damaging them, reducing product loss and saving money. Interested in learning more about automated packaging machines and how they can help your business? Keep reading this blog post!

1. What is automated packaging?

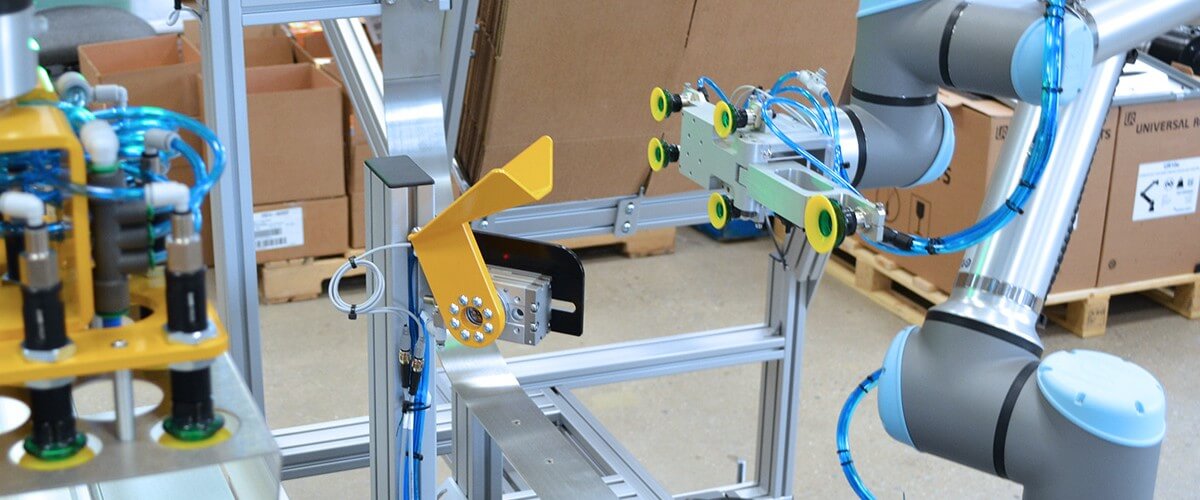

Let’s first establish what we mean by “packaging automation” and then move on to the advantages of automated packaging. We have developed packaging machines that can perform packaging actions on their own in order to fully automate the packaging process.

In some cases, packaging operations may be semi-automated, meaning some activities still require human labor. On the other hand, in other cases, all the packaging procedures can be done by the machine at the push of a button.

2. What is the importance of return on investment?

Many businesses don’t realize the importance of getting a good return on investment (ROI). An investment’s return on investment measures its effectiveness. Businesses need to generate more revenue than they spend in order to make money. ROI lets businesses know how much profit they are getting from their investment. There are many different automated packaging machines on the market that can help improve a business’s return on investment.

3. What are the benefits of an automatic packing machine?

Some benefits of automated packaging machines include:

1) Improve work efficiency

Packaging is a very time-consuming process. The use of automated packaging machines can make this process more efficient, allowing employees to do other tasks instead of packaging. With automated packaging machines, businesses can produce large quantities of items in less time. The improvement of work efficiency helps to improve the profit of the enterprise.

You need to move fast to meet the ever-increasing demands of today’s customers in order to compete in today’s fast-paced marketplace. If you don’t, you run the risk of falling behind your competitors and potentially losing business to those who are more agile than you.

Fortunately, investing in automated packaging technology may help you meet increased demand from this multiplication. This ultimately improves your ability to produce large quantities of packaging to meet customer requirements.

2) The machine can work around the clock

Automated packaging machines can also work around the clock, which is another great advantage. This means companies can ramp up production without worrying about employees working overtime. Additionally, packaging machines are less prone to error than human workers. This helps reduce product loss, which is another added benefit.

In today’s business world, being able to produce items quickly and efficiently is very important. Investing in automated packaging machines can help businesses stay ahead of the competition and improve profits. If you’re looking for ways to increase your business’s return on investment, automated packaging machines could be the answer.

3) Improve customer satisfaction

The modern consumer is more discerning than ever, and it goes without saying that they want value for money. So even the slightest variation in quantity, seal quality, or even the look and feel of your bag can have an adverse effect on your brand and sales. With the help of automated packaging equipment, you can meet and even exceed these consumer demands.

Packaging machines have the capability to precisely dimension packages, fully seal cartons to exact requirements, and ensure a clean and professional overall appearance of the final product. All of these elevate your company’s standing in the eyes of customers to a higher level.

4) Reduce labor costs

The labor-intensive procedure of packing goods can add significantly to the cost. Wages for labor need to be considered, and in some cases the amount of labor required may vary, making it more difficult to allocate a budget for the labor involved in packaging.

Although there is an initial investment cost for introducing packaging machines to provide an automated solution, the price per product packaged can be determined simply and the amount of labor required is greatly reduced. With automation, your employees can be used in other parts of the company where they can do a better job. This way, you don’t need as many people to complete the packing task.

5) Reduce work accidents

In addition to the waste generated by excess packaging, manual labor can also increase the chances of accidents on the job due to the repetitive nature of the duties that must be performed on a daily basis. You should know that employees are the backbone of any company and therefore very important to the success of your company.

If they are injured, there can be a significant negative impact on your company’s revenue, as you will have to pay claims and premiums because of the potential for them to become disabled. By automating your packaging line, you can free up employees who were previously engaged in packaging activities to perform other important tasks within the company.

In the end, this removes any possible liability not only to your employees but also to your finances. In addition, automatic packaging machines are equipped with various safety features to further reduce the risk of accidents in the workplace. Some of these features include emergency stop buttons, automatic sensors, and a failsafe.

6) Reduce material costs

If you are considering automating your packaging line, you must consider the cost of packaging materials.

You might be surprised to know that automatic packaging machines can actually help you save money on packaging materials. For example, automated machines can dispense the exact amount of material needed for each packaged product.

This reduces the amount of waste generated because there is no need to estimate the amount of material required for each product. In addition, automated machines can utilize recycled materials for packaging, further reducing your costs.

7) Reduce product giveaways

Using automated machines can also help you reduce product giveaways. This is because automated machines dispense the exact amount of product needed for each package, reducing the chance of giving away too much product. You can also be sure that each package contains the right amount of product.

8) Increased customer demand

The packaging process can be automated to produce better-looking products, and as a result, customers are more likely to be satisfied. This can lead to increased demand for your product, which can lead to increased sales and ultimately more profits for your company.

In addition, automated packaging machines can also help you save time when packaging your products. This is because automated machines can often pack products faster than manual packaging processes. As a result, you will be able to pack more products in less time, increasing sales and profits.

4. Conclusion

Automatic packaging machines can improve your business in several ways. Not only do they reduce the number of workplace accidents, but they also save on packaging material costs and time. Additionally, automated machines often produce better-looking products, and as a result, customers are more likely to be satisfied with what they receive.

Therefore, automatic packaging machines can help improve your business’ ROI in a number of ways. As a business owner, whether you are just starting out or have been in business for a while, one of your first tasks should be to develop a packaging program that is both effective and productive.

In order to develop a more effective brand, you should strive to enable your company to reliably meet customer expectations, taking into account the latest developments in the relevant industry. Hence, it is very necessary to use the latest technology in order to have a competitive advantage over other organizations. One of the best ways to achieve this is to invest in the right technology to automate your packaging operations. This equipment not only helps you properly manage growing demand but also helps you achieve your packaging goals.

Leave A Comment