As our technology advances, the use of robots and other autonomous applications in our daily lives increases as well. While cheaper robots use stepper or brushed DC motors, more advanced robotics require the use of servo motors. But what is a servo motor and why are they used in most industrial applications?

1. Introduction

In packaging, efficiency, precision, and reliability are key factors for successful operations. A key component that plays an important role in achieving these goals is the servo motor. This article discusses the importance of servo motors in packaging machines and how they can help improve their performance.

2. Understanding servo motors

The following is the definition, basic components, types, and working principle of servo motors:

1) Definitions and basic components

Servo motors are electromechanical devices that convert electrical signals into rotational motion. The system consists of a motor, a feedback sensor (usually an encoder or potentiometer), and a control board. Feedback sensors continuously monitor the motor position and communicate it to the control circuitry, ensuring accurate positioning and motion.

2) Types of servo motors

DC and AC servo motors are the two main types. DC servo motors use direct current, while AC servo motors use alternating current. Both types can be further divided into brushless and brushed motors, depending on their construction.

3) How servo motors work

Servo motors work by receiving an input signal from a controller, usually in the form of voltage or pulse width modulation (PWM). Circuitry processes input signals and sends commands to the motor, adjusting its position, speed, and torque as needed. Feedback sensors constantly measure the motor’s position, providing real-time data to the control circuitry to ensure precise control.

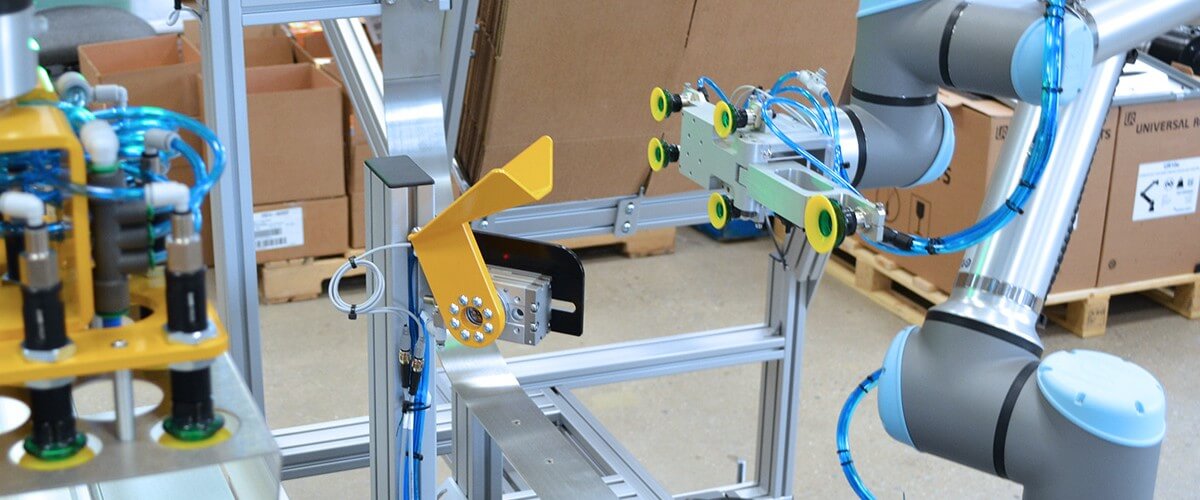

3. Application of servo motor in packaging machinery

The following is about the application of servo motors in packaging machinery.

1) Positioning and motion control

In applications requiring precise positioning and motion control, servo motors excel. Packaging machines can be used to accurately position products, labels, or sealing components, ensuring consistent and high-quality packaging.

2) Speed and torque control

Packaging machines often need to run at different speeds and require different levels of torque to handle different types of products or packaging materials. Packaging machines can adapt seamlessly to these varying demands with servo motors, which provide excellent speed and torque control.

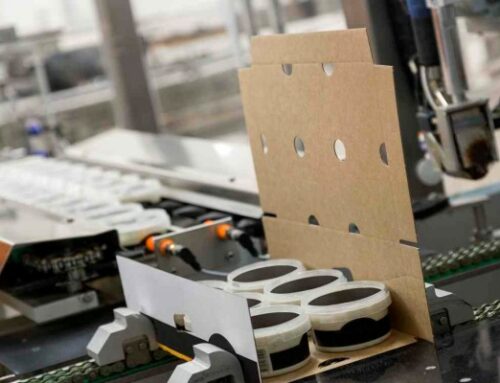

3) Precise filling and sealing

Accurate filling and sealing are critical to maintaining product quality and minimizing waste during packaging. Filling systems, such as auger fillers and volumetric cup fillers, and packaging machines rely on servo motors to ensure hermetic seals.

4. Benefits of using servo motors in packaging machines

Here are some benefits of using servomotors in packaging machines.

1) Improve efficiency and productivity

Servo motors increase the efficiency and productivity of packaging machines by providing precise control. The enhanced precision provided by servo motors reduces errors, minimizing downtime and waste.

2) Improve precision and accuracy

Packaging machines can perform tasks with high precision thanks to servo motors, which provide excellent positioning and motion control. This results in consistent, high-quality packaging.

3) better adaptability and flexibility

Due to servo motors’ ability to adjust speed and torque, packaging machines can easily adapt to different products or packaging materials, thus increasing their versatility and reducing their maintenance requirements for manual adjustments.

4) Energy savings and lower operating costs

Packaging machine operators can save significant amounts of money by using servo motors due to their high energy efficiency. By consuming less electricity and reducing waste, servo motors help reduce operating costs.

5) Improve reliability and durability

In packaging machinery, servo motors are a reliable choice due to their ability to withstand harsh operating conditions. Their durable construction and efficient performance reduce maintenance and extend service life for further cost savings.

5. Servo motors for different packaging machinery models

The following are servomotor models for different packaging machinery:

1) Vertical filling and sealing machine

In the vertical form fill seal machines, servo motors control the film pulling, filling, and sealing processes. Their precision and speed help ensure consistently high-quality packaging.

2) Horizontal packaging machine

In horizontal flow packaging machines, servo motors are used to control the product feeding, film pulling, and sealing process. Precision positioning and motion control contribute to efficient and accurate packaging.

3) Rotary pre-made pouch packaging machine

Servo motors can be found in rotary-preformed pouch packaging machines where they control the pouch picking, opening, filling, and sealing process. Their ability to accommodate different bag sizes and types makes them ideal for these versatile machines.

4) Spiral Filling Machine

The auger filling machine relies on servo motors to control the auger rotation and filling process. A precise speed and torque control ensure accurate filling.

6. Choose the right servo motor for your packaging machine

Here are some suggestions on choosing the right servo motor for your packaging machine for your reference.

1) Determine your application requirements

You should first determine your specific application requirements, such as positioning accuracy, speed, and torque, before choosing a servo motor for your packaging machine.

2) Evaluate Motor Specifications

Identify the servo motor that meets your application requirements by comparing its specifications. Motor type (AC or DC), power rating, torque, speed, and encoder resolution are key specifications to consider.

3) Choose the right motor type

Choose the servo motor type that best suits your packaging machine based on your application requirements and motor specifications. Consult the motor manufacturer or supplier to ensure you are making the right choice.

7. Integration of servo motors in packaging machines

The following is the integration of the servo motor in the packaging machine:

1) Install and configure the servo motor

Proper installation and configuration of your servo motor are critical for optimum performance. Consult a professional if necessary and follow the manufacturer’s instructions.

2) Set up the control system and software

Integrating servo motors into your packaging machine requires setting up a proper control system and software. This may involve configuring a programmable logic controller (PLC) or other control device to communicate with the motor and manage its operation.

3) Maintenance and Troubleshooting Tips

Regular maintenance and inspection of servo motors help ensure their reliability and longevity. Proactively address any problems or anomalies that arise during operation, and consult a professional when needed.

8. Technology trends for servo motors in the future

Based on the current situation, we have made the following prediction on the future technology trend of servo motors.

1) Advances in motor design and materials

As motor design and materials improve, servo motors will become more efficient, compact, and powerful.

2) Smart Motors and Industry 4.0

Smart technologies and the Internet of Things (IoT) will enhance the monitoring, diagnostics, and control of servo motors, contributing to Industry 4.0. Servo motors in packaging machinery will benefit from these advances to improve their performance and adaptability.

3) Energy-saving motor

With energy efficiency continuing to be a priority for businesses and industries, more energy-efficient servo motors will be developed. Operators of packaging machines will be able to reduce their energy consumption and operating costs with these motors.

4) Greater Accuracy and Speed

Technological advancements will enable the production of servo motors with greater precision and speed capabilities. These improvements will further enhance the performance of packaging machines, thereby increasing productivity and product quality.

5) Machine Learning and Artificial Intelligence

Incorporating machine learning and artificial intelligence (AI) techniques into servo motors could lead to self-optimizing systems that can learn from their environment and adjust their performance accordingly. This will make packaging machines more versatile and efficient.

9. Frequently asked questions

Here are some common questions:

1) What are the main advantages of using servo motors in packaging machinery?

The main advantages of using servo motors in packaging machines are their excellent precision, speed, and torque control. These features help improve efficiency, accuracy, and reliability in the packaging process, resulting in higher productivity and lower operating costs.

2) Can I retrofit my existing packaging machine with servo motors?

In many cases, existing packaging machines can be retrofitted with servo motors. Such an upgrade, however, depends on a variety of factors, including the machine’s design, compatibility with servo motors, and desired performance. Consult a professional to determine if retrofitting a packaging machine with a servo motor is feasible.

3) How to maintain the servo motor in the packaging machine?

Regular maintenance and inspections are essential to ensure the reliability and longevity of servo motors in packaging machines. In addition to monitoring the motor’s performance, this may include checking for signs of wear and cleaning and lubricating it. Consult a professional if necessary and follow the manufacturer’s instructions.

4) How do I choose the right servo motor for my packaging machine?

Choosing the right servo motor for your packaging machine begins with determining your application requirements, such as position accuracy, speed, and torque. Find a servo motor that meets these requirements by comparing the specifications of different models. Finally, consult the motor manufacturer or supplier to ensure you are making the right choice.

5) What are the future trends in servo motor technology for packaging machines?

In the future, servo motor technology for packaging machinery will include advances in motor design and materials, smart motors, Industry 4.0 integration, energy-efficient motors, higher precision, and higher speeds. incorporation of machine learning and artificial intelligence. In the packaging industry, these innovations will further enhance the performance of servo motors.

10. Conclusion

Servo motors are an essential part of packaging machines, providing excellent positioning, speed, and torque control. Their integration with these machines helps improve efficiency, accuracy, adaptability, and reliability, ultimately increasing productivity and reducing operating costs. As technology continues to advance, we can expect servo motors to play an even more important role in future packaging machinery, driving industry innovation and setting new standards.

Leave A Comment