When it comes to designing packaging for your brand, you are faced with countless options. When choosing packaging for your brand, cardboard thickness is an important factor to consider.

The following is a complete guide to cardboard thickness:

1. Why is cardboard thickness important?

- it protects content

- it helps survive in transit

- Minimize Shipping Costs

- promote the best printing

At first glance, all cartons look the same; however, cardboard thickness is more important than you might think. The reasons are as follows:

1) Protect the contents of the package

For starters, the thickness of the cardboard determines the level of protection of the box. This is especially important for delicate and fragile items that require extra insulation and protection throughout transit.

The last thing you want is for your product to reach customers in pieces, and thicker cardboard can help you prevent that from happening.

2) Shipping Survival

The thickness of the cardboard also influences the survival rate of the box during shipping. We’ve all received a box that looks like it’s been wrung, with tears and punctures all over it.

The shipping process can be tough and stressful, so make sure your boxes are prepared to be handled by multiple sets of hands along the way.

3) Minimize shipping costs

In theory, thicker boxes mean heavier boxes, resulting in higher shipping costs. At the same time, though, you also need to consider the money you’ll save by using a thicker box if it means you deal with fewer damaged items to return and replace.

4) Promote the best printing

These days, it’s not enough to just use a boring brown cardboard box. Instead, you need to brand the box by printing your brand logo, colors and product on it.

However, the thickness of the paperboard will affect the results of your printing, so this is something to consider if you want high-resolution printing on your branded boxes.

2. Different measurement methods of cardboard thickness

There are several ways to measure cardboard thickness. For example, you can use grams per square meter (GSM), point (PT), flute and board.

Here’s what you need to know about each of the different methods so you can choose the right board thickness for your product:

1) Grams per square meter (GSM)

Grams per square meter or GSM is a unit of measurement used to measure the weight, length, and width of packaging materials such as corrugated cardboard. GSM is one of the most popular and accurate methods of measuring cardboard thickness.

However, converting GSM to units you can actually understand can be difficult.

Here are some examples of different types of paper/board to give you a better grasp of measuring board thickness using GSM:

- 35 to 55 GSM usually used for newspapers

- 90 to 100 GSM typically used for printing paper

- 120 to 140 GSM typically used for posters

- 210 to 300 GSM typically used for brochures

- 350 to 400 GSM typically used for packaging

You’ll want to choose a cardboard product with a GSM above 350 if you’re looking for thick, strong packaging.

In addition, higher GSM does not necessarily mean heavier weight. While GSM does take weight into account, remember it’s only one of three factors.

2) Point system (PT)

PT is also used to measure corrugated paper used in cardboard boxes. Each “point” in the point system represents 1/1000th of an inch. You can find a paper from the thinnest 8 points all the way up to the thickest 16 points.

3) corrugated groove

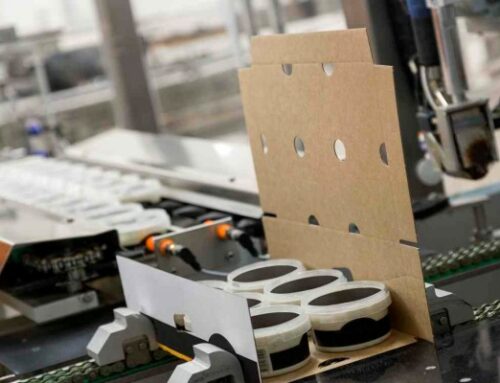

Corrugation flutes are another method of measuring board thickness. Corrugated “flute” refers to the corrugated paper sandwiched between the cardboard liners of corrugated boxes. These flutes are designed to make the box more insulated and protected.

There are several different flute sizes to choose from, from small to large. Flute sizes are not named by thickness, but by the order in which they were invented. Here is a list of some of the different flute sizes available and their corresponding names:

- The flute is 5 mm or 1/4″ thick

- B slot 3mm or 1/8” (0.125”) thick

- C flute thickness 4mm or 11/64”

- D slot thick 2mm or (.085”)

- E-slot thick 1.5 mm or 1/16” (.0625”)

- F groove thickness is 0.6 mm or 1/32”

C flute is by far the most common type of corrugation and can be used in a variety of different products.

4) Corrugated cardboard style

You can use the corrugation board style to determine the board thickness. Corrugated board styles refer to the different combinations of corrugated paper and liner in a corrugated board box.

Most corrugated cardboard boxes are single-wall panels, which means they consist of two liners surrounding a single fluted layer. But there are also single-panel, double-panel, and three-panel.

The single panel consists of backing paper and corrugated paper. Since this type of cardboard is not as durable and strong as other types, it is ideal for inner packaging components.

Double wall panels consist of three linings surrounding two corrugated sheets. For packaging heavy or fragile items that require extra protection during transit, this type of paperboard is ideal.

Finally, the three-ply wallboard consists of four linings surrounding three pieces of corrugated paper. This type of paperboard is ideal for packaging extremely heavy items such as electrical appliances and industrial equipment that require maximum protection during transport.

3. How to choose the best packaging

Consider the following factors when choosing packaging:

- content

- shipping

- Budget

- design

- Who do you design the packaging with

Now that you have a better understanding of why board thickness is important and how to measure it, how can you choose the best packaging for your product?

Step 1: Consider Content

When choosing the best packaging for your brand, you first need to consider the contents of the package. Are your products extremely fragile and need extra protection?

Is your product particularly heavy and requires very strong and durable packaging? These are two important components to keep in mind.

Also, keep the dimensions of the product in mind when choosing your packaging. You want to choose boxes that are large enough to hold your products comfortably, but not so large that they will move around a lot.

Additional packaging such as custom inserts and dividers can be a good idea to help keep your products safe.

Step 2: Consider the Shipping Process

When choosing the best packaging for your brand, you also need to consider the shipping process. Do you pack your orders yourself and use local delivery services?

If so, then you probably don’t need very durable packaging.

However, suppose you use a third-party logistics company to pick, pack, and ship your products. In this case, you have to consider how much your hands are on the package will affect the likelihood of damage in transit.

Therefore, you may want to consider purchasing thick and durable packaging to prevent damage and protect your product.

Step 3: Consider your budget

Of course, budget is also an important factor when choosing branded packaging. Not only do you need to consider the cost of the packaging components themselves, but also the cost of shipping along with those packaged items, since shipping costs are determined by size and weight.

Remember that thickness doesn’t necessarily correlate to weight. Also, keep in mind that sometimes it pays to spend a little more for thicker cardboard because it will provide more protection for your product.

Step 4: Consider the Design

Consumers expect and respond to branded packaging with eye-catching designs that contribute to a memorable unboxing experience. Board thickness correlates with print quality as printing tends to look better on higher-quality paper with a higher GSM. So if you’re looking for photo-quality prints, consider choosing paper with high GSM.

Step 5: Work with a packaging expert

Even with all this information on cardboard thickness, you may want to work with a packaging expert who knows this stuff to help you choose the best packaging for your brand.

Look for an experienced and reputable company that offers custom packaging solutions, volume discounts, and fast turnaround times.

Leave A Comment