For all your packaging needs, corrugated packaging is durable, strong, and flexible. What you need to know about using it in your packaging.

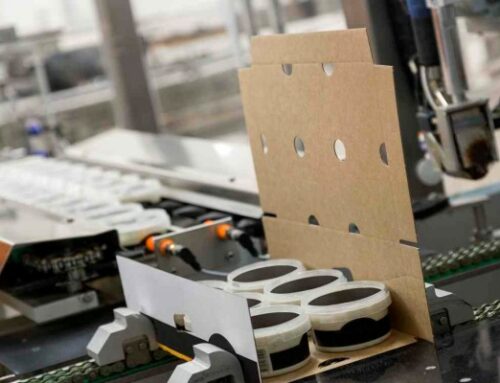

Corrugated packaging is one of the most commonly used packaging types for brands across industries. This type of packaging retains a high value as it protects the packaged items from moisture while maintaining the quality of the food and preventing spoilage.

It is considered one of the most sustainable types of packaging on the market, with a high rate of recovery and recyclability. From fragile to lightweight products, packaging is reliable and easy to use.

This type of packaging comes in many forms, including corrugated kraft mailer boxes for items sent by mail or boxes for those heavy items.

This type of packaging focuses on preservation and comfort while transporting items, while also protecting the environment, as landfill remains a major concern.

Corrugated packaging is also a cost-friendly packaging alternative that allows businesses to increase efficiency while attracting more customers. This is the ultimate guide to corrugated packaging.

1. What is a flute in a corrugated box?

One of the first questions people ask when dealing with corrugated packaging is, “What is the corrugated paper in the corrugated box?” In this case, the flute is not a musical instrument, but it contributes to the way the packaging works as it is used for reinforcement or Reinforced cardboard.

Corrugated is usually classified according to the thickness of the paper used, from smaller foldable single-wall corrugated to larger double-walled corrugated.

The corrugated paper looks like wavy lines, especially when glued to cardboard to form corrugated cardboard.

They provide rigidity to your packages, helping them withstand any crushing during packaging for shipping. In addition to single- and double-wall corrugated boards, there are triple-walled corrugated types that offer more cushioning, making them ideal for shipping.

There are different types of corrugated cardboard, from A corrugated cardboard to F corrugated cardboard. E-flute is a particularly popular branded packaging as it is a tighter, eco-friendly, low-fiber packaging with strong construction and high value.

E-flutes in corrugated packaging are used in custom shipping boxes and retail packaging. For cosmetics, jewelry, and footwear brands, F-flute packaging is especially convenient.

2. Corrugated is sustainable

Brands are increasingly conscious of their social responsibility, creating sustainable products that reduce their footprint without sacrificing product quality.

Consumers increasingly associate sustainability with trust when choosing brands. Therefore, as long as the demand for sustainable, recyclable packaging remains stable, the corrugated packaging market has grown significantly and will continue to grow.

Corrugated packaging like Kraft Mailers is popular because it’s made from recycled kraft material and can be composted or recycled at home. It can handle simple or more complex designs and is extremely durable for shipping items that must remain flat during transit.

To create a seamless unboxing experience, the packaging is made from Forest Stewardship Council (FSC) certified materials and has a tamper-evident closure.

Another benefit of corrugated cardboard such as boxes and F-groove board is that they are always renewable. Corrugated paper materials reduce packaging costs and pose no environmental threat because they can be used multiple times. They are easy to fold and can be disposed of with ease as they are compostable.

3. Compared with cardboard, paper corrugated board is stronger and more reliable

People often confuse corrugated cardboard with cardboard, thinking they are the same material. Cardboard is a heavy-duty paper stock used to make items that fill supermarket aisles, such as cereal boxes, while corrugated is stronger thanks to its corrugated backing and medium.

These materials are bonded together to form multiple layers of fibreboard, adding thickness and uniformity to create a reliable packaging solution.

As mentioned above, corrugation thickness plays a key role in measuring the strength of corrugated packaging. Grooves can be found on the edges of the box and are compressed.

During production, the box is slightly compressed and the grooves on the edges are flattened. To measure the true thickness of the groove, look at the groove in the middle of the box, where there is no compression. You can use the corrugated flute chart to evaluate the thickness of different flute types.

For corrugated boxes, samples are created using samplers that are cut at the edges without any compression. As a result, the samples seem to have taller flutes because they are not compressed.

When corrugated boxes are mass-produced, the edges will appear more squashed than before. Most mailers come with standard E-flute corrugated cardboard, which is lightweight while providing premium protection for items shipped through the mail.

Leave A Comment