In October 2019, we received an order from Poland. It was sold by one of our European agents, Company G. In Europe, there are some similar cardboard box machines, but the customer still chooses us because of our low prices, good quality, and excellent service.

Our machine is expected to arrive at our customer’s factory in Poland on January 7, 2020. On January 5, 2020, our after-sales engineer arrive in Poland on time, we would provide our customers with the most timely after-sales installation and training services.

(Our after-sales service is free of charge, there is no training fee and no labor fee, customers just need to provide our after-sales engineers with round-trip airfare, solve the problem of accommodation and food.)

Our CNC cardboard box machine is a multi-functional and highly integrated equipment, a machine integrated with automatic paper feeding, automatic slotting, longitudinal cutting, transverse cutting, longitudinal crimping, transverse crimping, portable hole die-cutting, and other functions.

However, multi-function not means hard installation. On the contrary, the installation process is very simple. It only needs to make a simple horizontal adjustment, tool adjustment, and then connect the air source and power supply, it can be completed in a day.

Our customer uses the cardboard box machine to solve the problems of order diversification, large carton sizes, and cardboard slitting. The BM2508-Plus CNC cardboard box machine has the function of fast order change, whether the carton size change or box type change, it can complete the order change in 20-50 seconds.

Besides, using the leading edge feeding structure, the feeding efficiency is very high, there is no problem of the cardboard slipping and cannot be fed in.

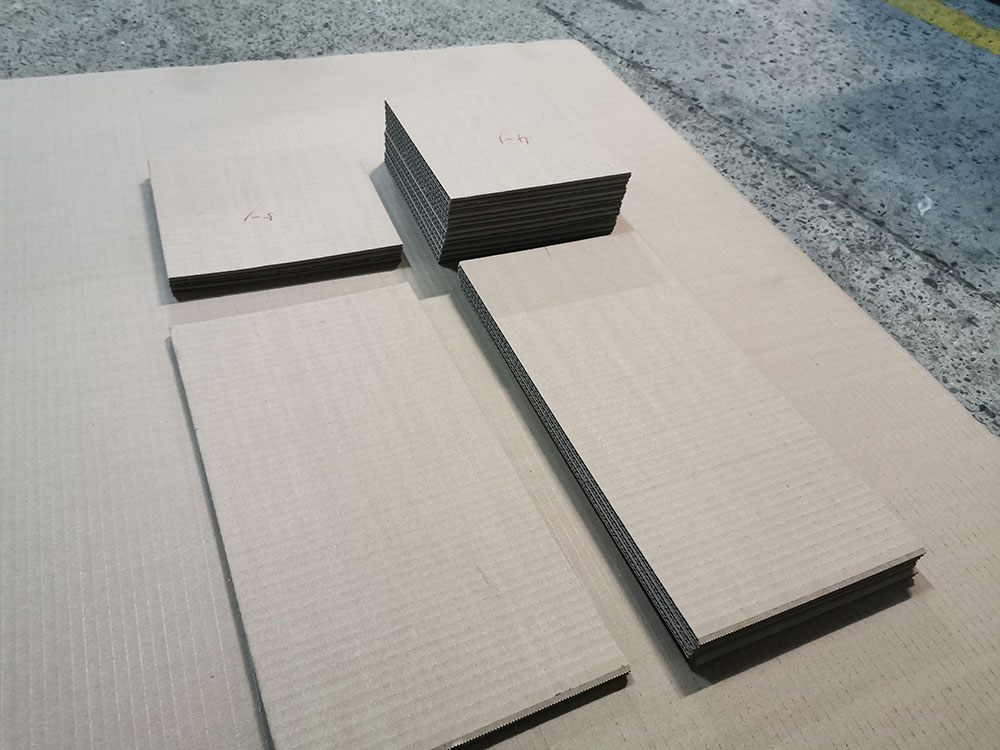

It can meet the feeding needs of different widths of cardboard, from 200mm width to 2500mm width, it is suitable. Especially large cardboard, it can also place many sheets at once, which is greatly reducing labor intensity.

After the installation of the box machine was completed, it soon entered the pilot production and staff training phase. The equipment is operated by two young men, who receive the knowledge very quickly. Plus the equipment is relatively simple to operate, they know how to operate the equipment less than an hour.

After a week, the operator has fully mastered the operation, maintenance, and parts replacement of the equipment. During this time, their daily orders are slowly filmed, very satisfied with the quality of the carton boxes made by our equipment, their boss highly praises our equipment.

Leave A Comment