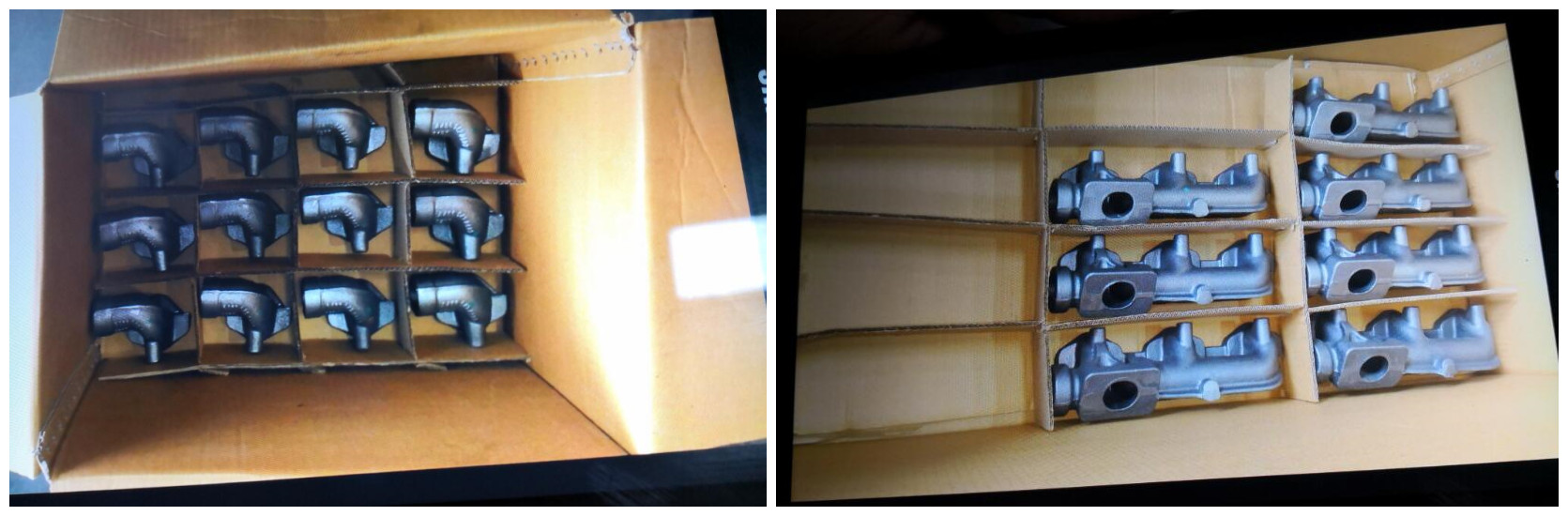

Singh comes from a reputable family in India, who runs a carton box company in Pune, Maharashtra. They supply different size carton boxes to package the car accessories. As the car accessories have different sizes, and the quantity is often too small, they can’t use the traditional die-cutting box machine to produce it. Besides, the delivery time is also too tight, sometimes the order was just placed today, the carton boxes are needed the next day.

This was a really big headache for Singh because he took large orders from these car factories and small orders had to be made or large orders would be lost. He had already lost many customers due to untimely deliveries, so he wanted to find a carton box building machine that could make small batches of cartons boxes quickly.

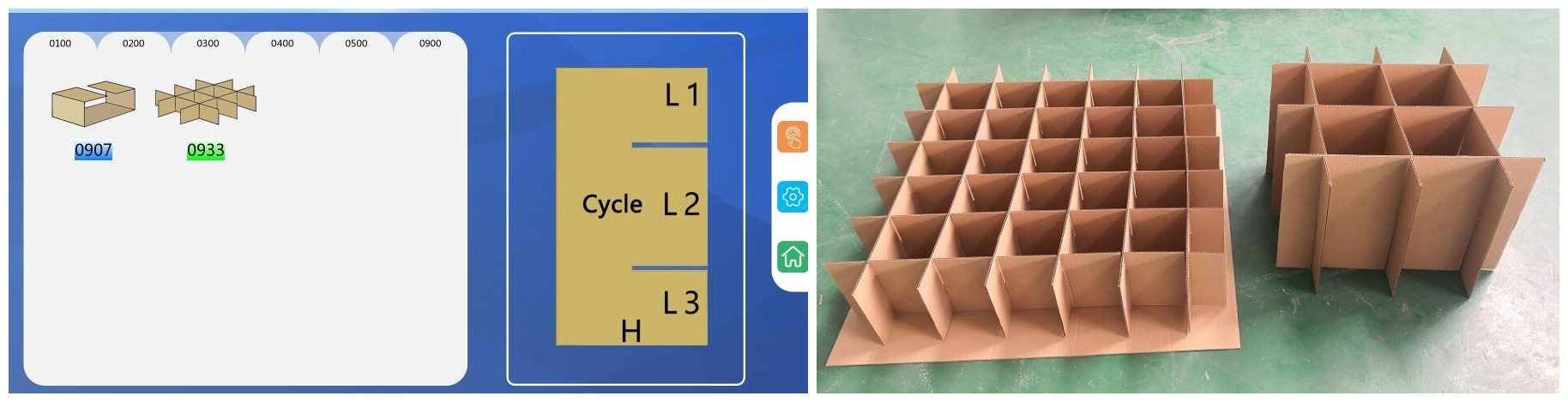

At the 2019 International Corrugated Packaging Show in Shanghai, Singh saw our Carton box building machine BM2508-Plus. We showed him how to make carton boxes and replace the order. The quality of the carton boxes is the same as the box from the traditional die-cutting box machine. However, our machine can replace the order in a minute.

All of these functions are in line with his expectation, later, Singh used all the boxes in our machine library. Especially the 0933 grid box, this is the most headache for him before, itis difficult to make such carton boxes for them.

Our engineer demonstrated how to make a grid box with our machine on site. We can produce about 8 pcs boxes in 1 minute, and changing one order in less than a minute. According to this efficiency, Singh roughly calculated that he can complete the small batch of orders per day to 5 to 10 times more than before. It can bring him great benefits, and help them to receive many new customer orders.

After confirming that our BM2508-Plus carton box building machine was able to solve all his problems, Singh spoke to our sales and technical staff in detail about the delivery, packaging, power supply, air supply, etc., all as per Indian standards, and made an appointment with us to order one machine.

After 10 days back to India, Singh signed a formal contract with us and called us for the equipment. Two months later, the equipment ordered by Singh was shipped to India.

After-sales on-site in India

Normally, our agent will responsible for the after-sales work, such as machine installation, debugging, training, etc. If we don’t have any agents in this country, we will send our factory engineer to finish the after-sales work.

All the after-sales work is free, it includes labor, installation, and training. All you need to do is to provide us with the cost of airfare and room and board for our engineers. At present, we don’t have an agent on the Indian, so we send engineers to serve our customers.

Our India client prepared the power supply, air source, crane, etc. in advance. The floor is very flat, our installation job is smooth, in the end, we use morning time to finish this installation.

After the installation, the next job is training. The client arranges two young men to operate the this carton box building machine They have only a junior high school degree, but they know a little English, so the client arranged for them to learn the equipment.

Although it is a bit difficult in language and communication these two operators still mastered the operation of the equipment in 2 days.

After a week, all the training was complete and both the staff and manager were very satisfied with the equipment.

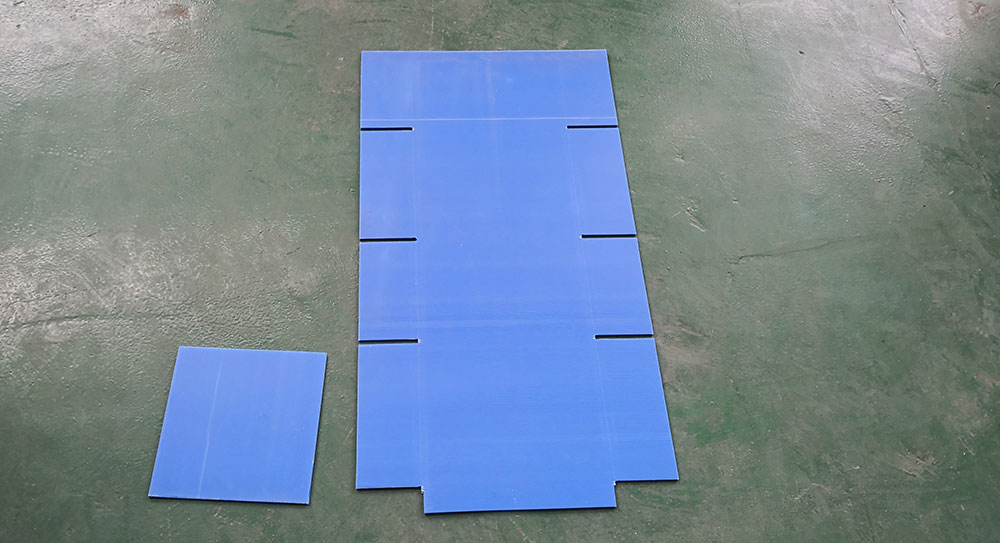

Sometimes, they have some special needs. For example, they use hollow plastic sheets to make boxes, it also works well.

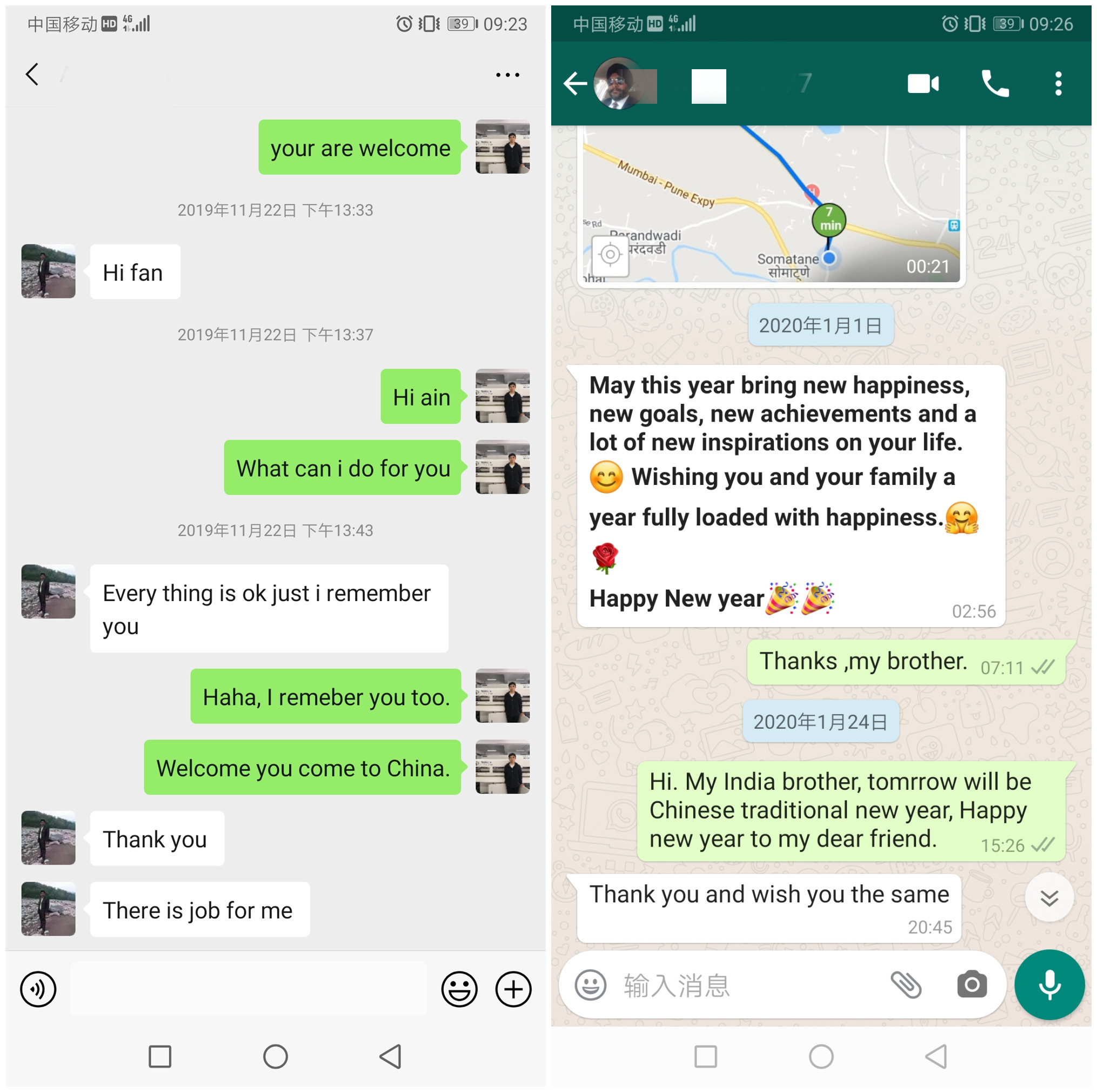

After we finish the after-sales work successfully, on the basis of the benefits to both sides, we have also established a deep friendship. Win-Win is the purpose of our AOPACK Boxmaker.

Our Carton box making machine has been working well in the customer’s factory. We keep a good relationship with our friends.

Leave A Comment