Aopack Boxmaker intelligent packaging system uses the human-machine interface, we take 0201 box type as an example to introduce the normal box production process.

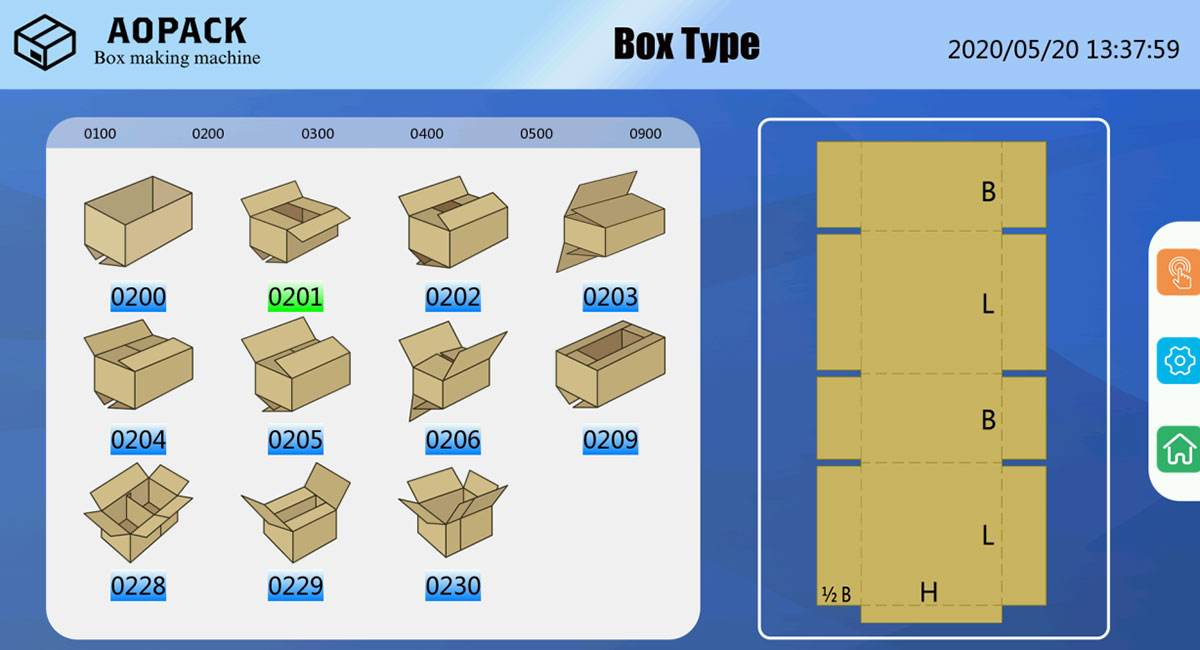

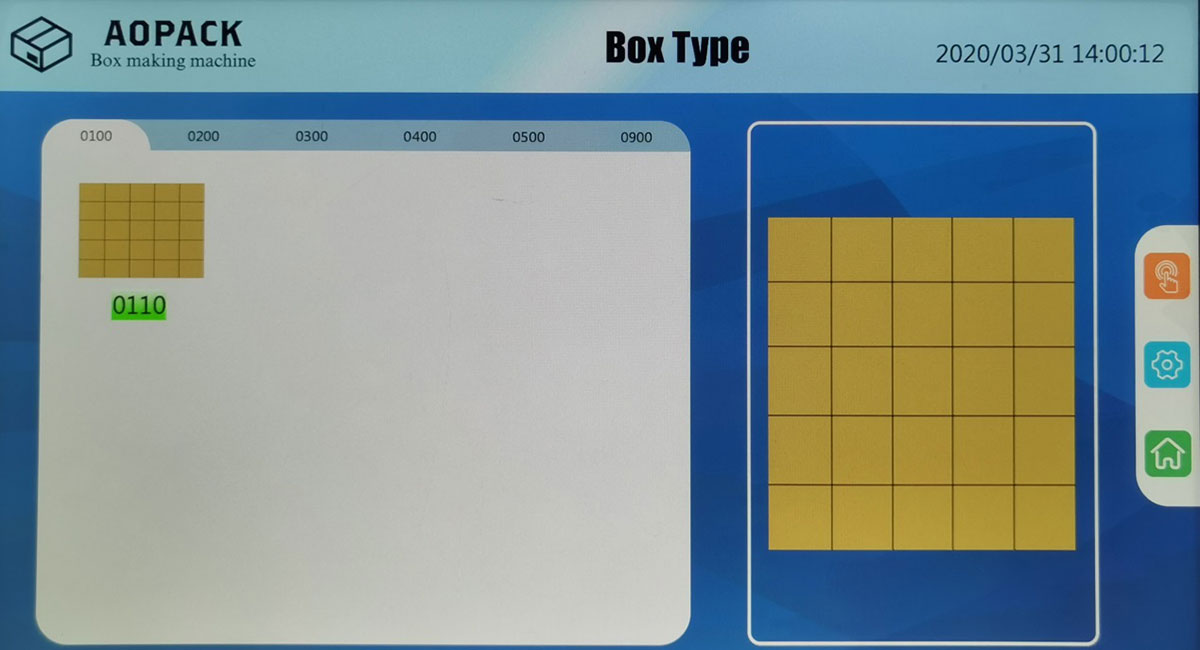

Step 1: Choose 0201 box type

Click the “Box type” button on the touch screen, select the 0200 code base, click the 0201 code, the touch screen will display the schematic diagram of the box type code, click the box type diagram to enter the operation interface.

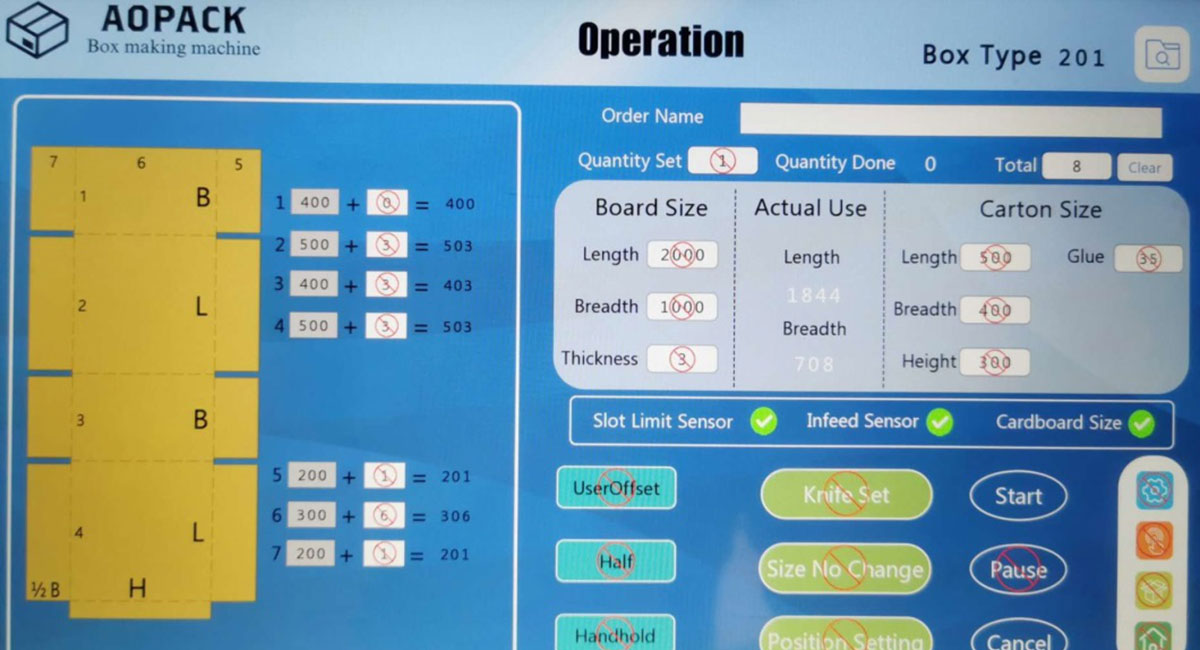

Step 2: Data Input

The data that need input include Quantity Set, Input Board Size, Carton Size. When you finished the Carton Size input, the screen will display the Required Board Size automatically.

Step 3: Knife Set

Click “Knife Set”, it needs about 50 seconds to finish knife set. Then adjust the distance between the front stop and the infeed table(the distance should be 1.3~1.5 thickness of the cardboard, next you can place cardboard, and lock left side guide, the cardboard need close the front stop.

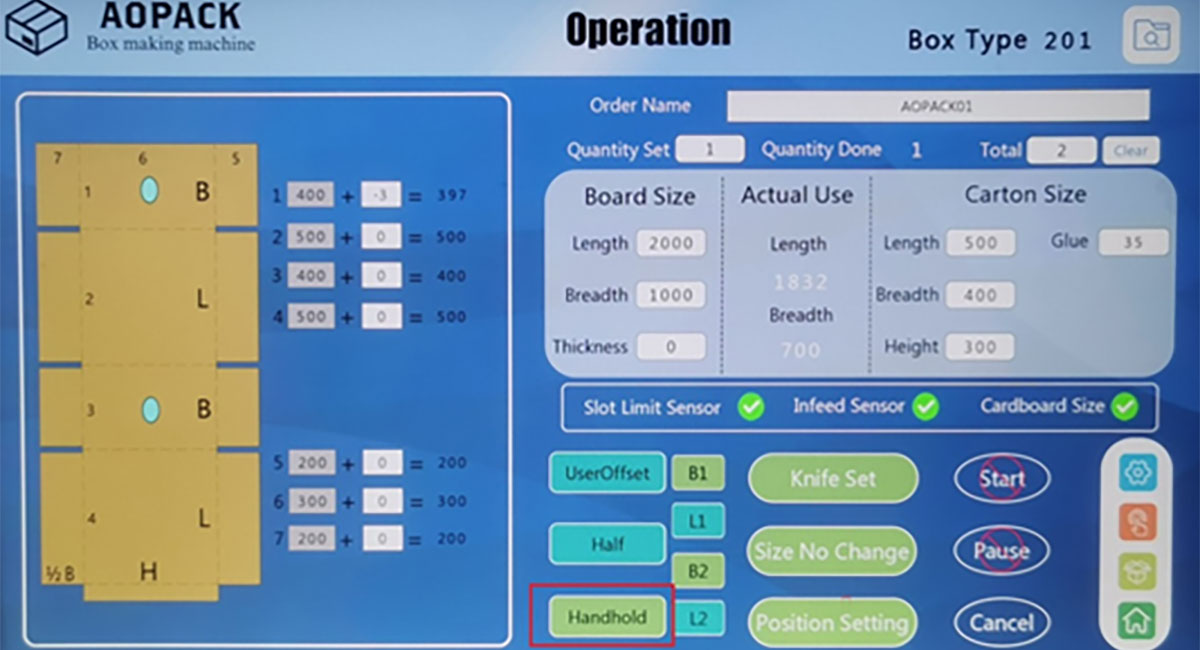

Step 4. Handhold

If you need handholes on the box sides, Click the button to select the handhold punching position.

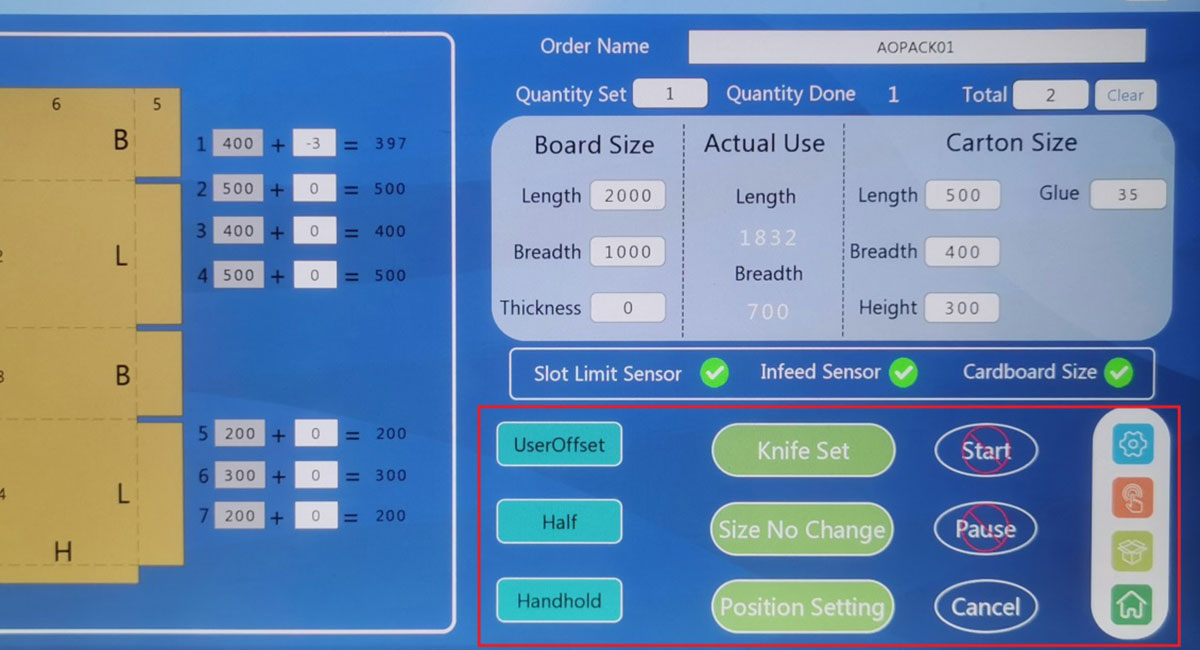

Step 5. Box making

After finishing all the settings, machine will do cardboard feeding, slotting, creasing, cutting, slitting automatically, then a box is made successfully.

For special box production

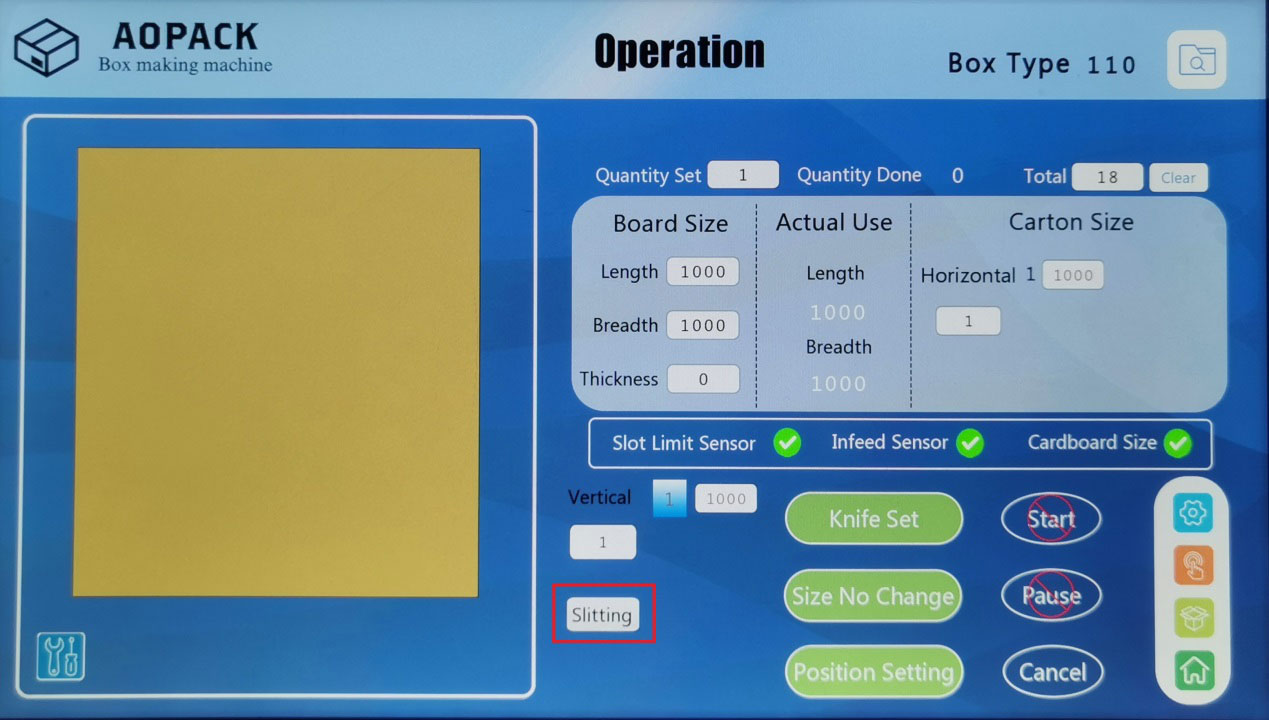

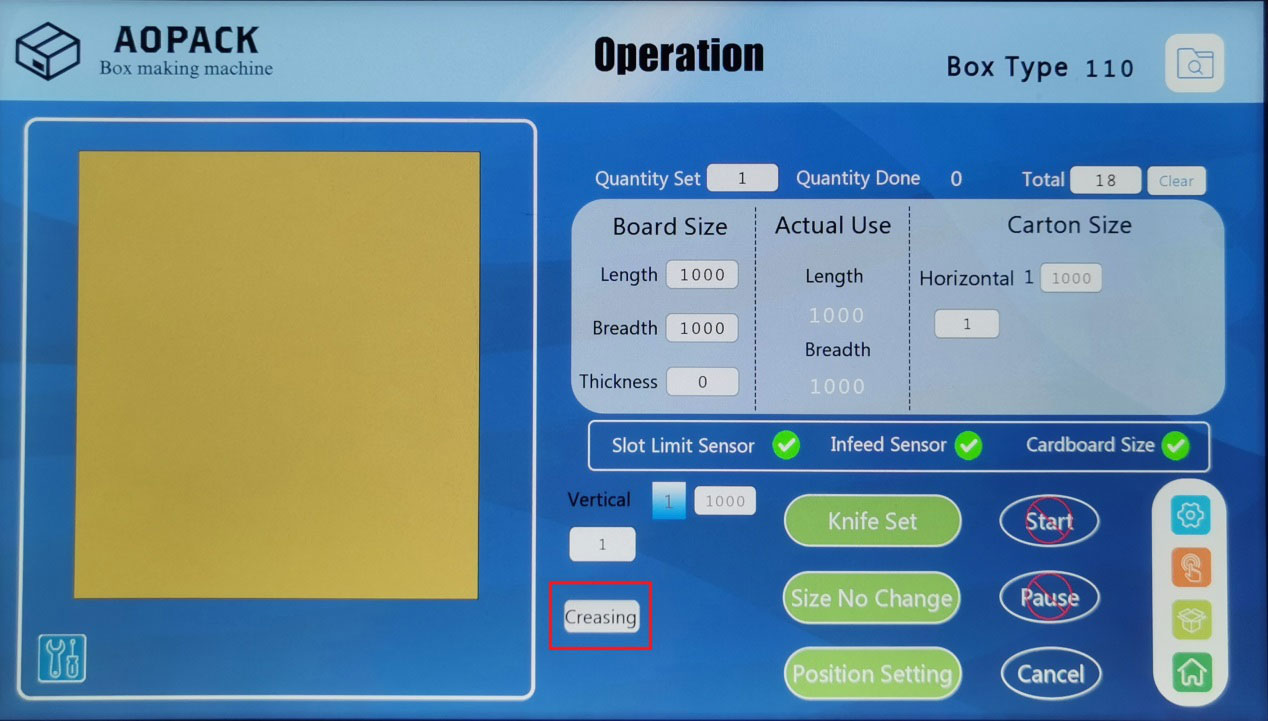

For special box production, we take 110 types as an example, the main difference is slitting or creasing.

Click the “Box type” button on the touch screen, select the 0100 codebases, click the 0110 code, the touch screen will display the schematic diagram of the box type code, click the box type diagram to enter the operation interface.

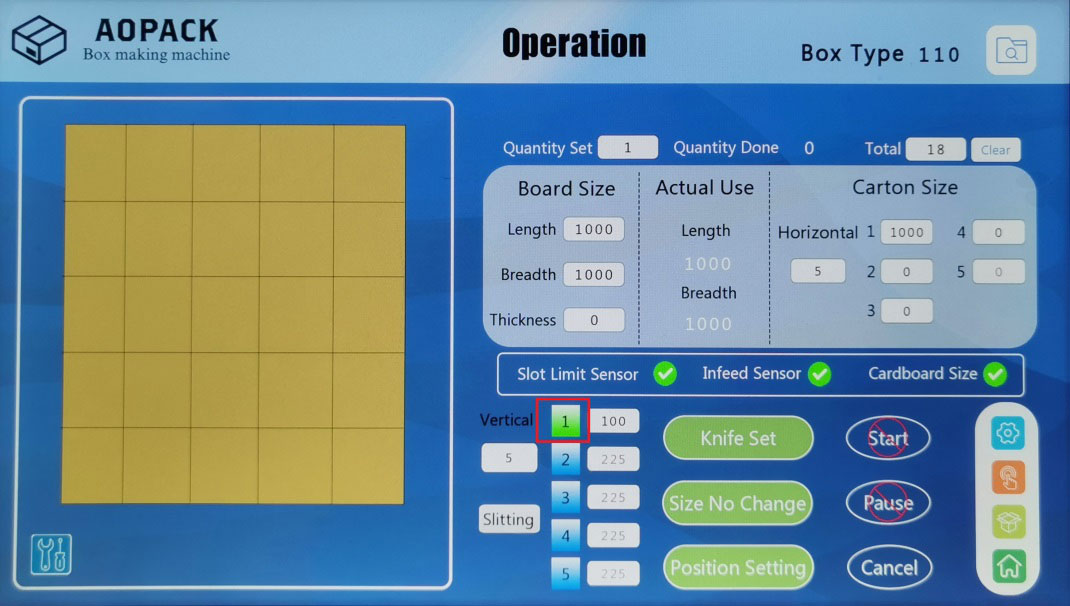

Enter the 0110 box-type operation interface, select the “slitting”or “Creasing” function

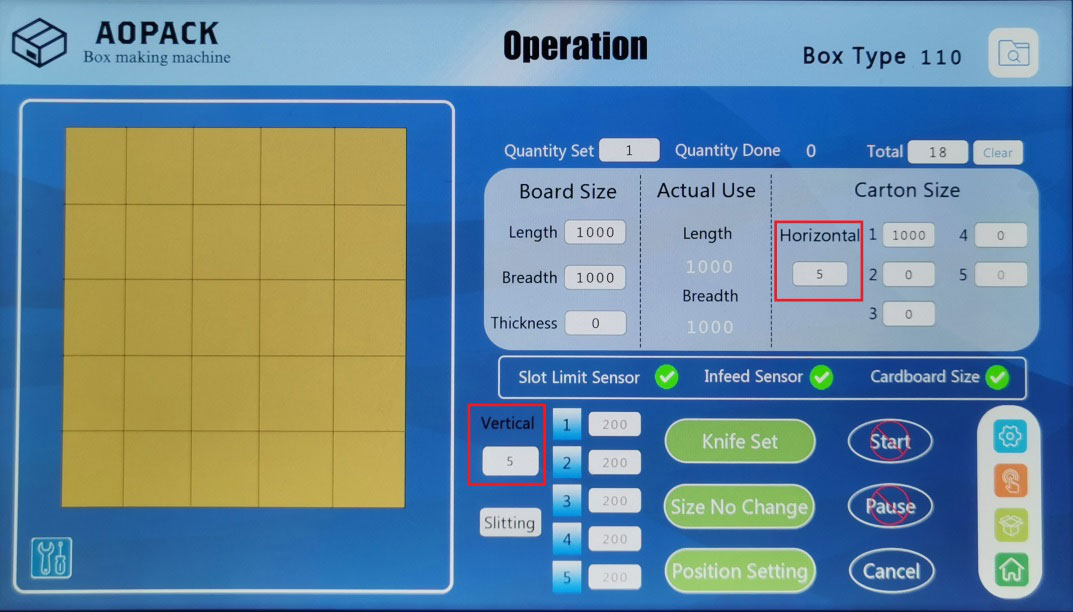

Set the number of sections in Horizontal and Vertical (Max 5)

Horizontal: Enter the number of sections you want to cut the board horizontally and the length of each section.

Vertical: Enter the number of segments that you want to divide the cardboard vertically. The system automatically calculates the average value of each segment. Click the number in front of the data frame. The number turns green to indicate that you can manually rewrite the data. Blue means to restore the default average.

For example,divide one cardboard vertically into two sections.

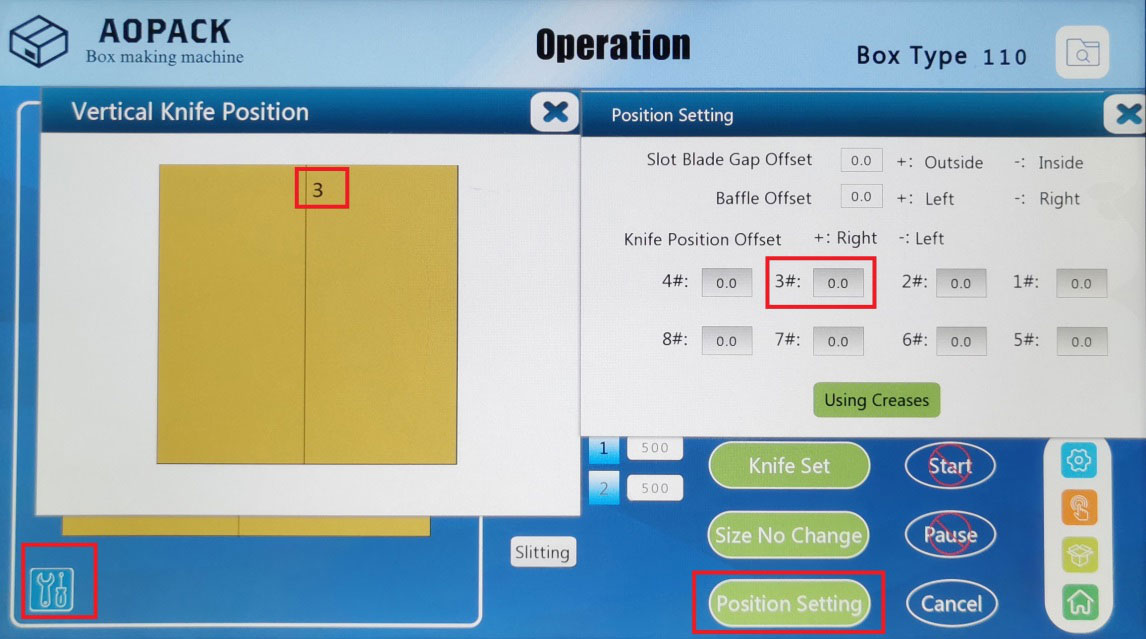

If the cardboard is not divided in the middle, you can click the icon ![]() in the lower-left corner to confirm which knife is used for creasing or slitting, and then go to “Position Setting” to manually adjust it. The adjustment will be canceled after the order replaced.

in the lower-left corner to confirm which knife is used for creasing or slitting, and then go to “Position Setting” to manually adjust it. The adjustment will be canceled after the order replaced.

After setting the size, click “Knife Set”, then turn on the fan, and click ” Start “.

Leave A Comment