Welcome to this article, which is an in-depth guide to cardboard packaging machines, and if you’re looking for any information about cardboard packaging machines, you’ll find it here. So read on to learn more.

1. What is a cardboard packaging machine?

The cardboard packaging machine adopts formed cardboard, which can automatically and continuously package glass bottles, PET bottles, cans, large-mouth bottles, etc. Suitable for automatic production lines of beer, beverages, condiments, food, etc.

2. What are the characteristics of the cardboard packaging machine?

There are some characteristics of the cardboard packing machine below:

- Using automatic bottle separation technology, and online continuous operation; the whole machine adopts PLC control and fully automatic operation.

- Frequency control main drive; container grouping brushless servo motor.

- Standard chains and internationally renowned hot melt devices; self-lubricating chains and permanently lubricated bearings.

- Evenly apply glue according to running speed; electronically adjust glue length.

- Simple touch operation; multiple security protection.

- Slim body design and large sliding doors for easy entry and exit

- Adapt to a variety of bottle types, easy to adjust;

- Motors, cylinders, and electronic controls use imported brand components and standard parts to reduce spare parts inventory;

- Try to use 304 material, the whole machine is beautiful and generous.

3. What is the working principle of the cardboard packaging machine?

The main principle is divided into four modules: container inlet, container divider, cardboard inlet, and package forming device.

1) Container inlet

On the inlet conveyor belt platform, cylindrical containers are divided into multiple lanes by partition plates and pneumatic vibrating rails, while single-lane containers with special shapes are divided into multiple lanes by lane dividers.

2) Container Divider

The container divider is driven by two servo motor drives to separate containers gently and evenly. To handleless stable containers, such as five-jaw PET bottles, transition lanes can be used between the conveyor chains. After the containers are grouped, they are pushed out by the push rod.

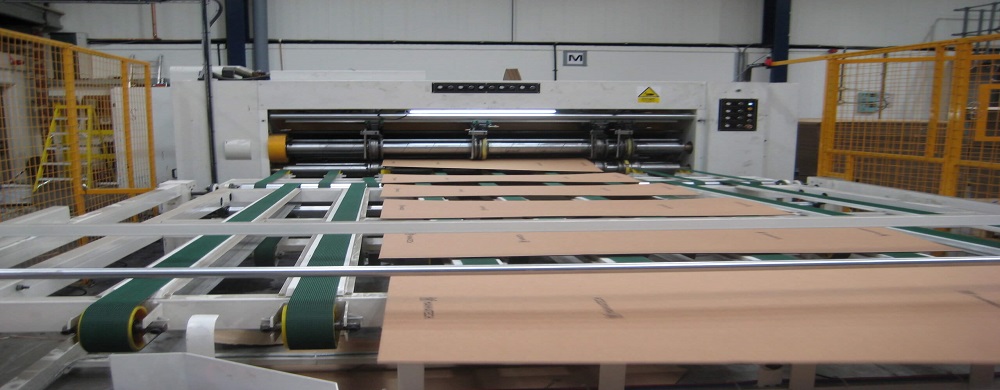

3) Cardboard inlet

The cardboard is neatly stacked on the roller conveyor and then automatically guided into the lifting cardboard storage located below the container inlet. The vacuum claws pick up the uppermost cardboard from the lifting storage and place it horizontally on the cardboard inlet.

4) Package forming unit

The cardboard is conveyed under the container group and the ends are folded by a mechanical device. The side cover is folded in with a rotary crimper, coated with hot glue by the spray nozzle, and pasted to the bottom cover. The endless sealing chain presses against the bottom lid and takes the package through the wrapping machine. Then, the top cover is folded off and glue is applied to the sealing edge. Finally, the sealing chain closes the top cover from above. Since the package runs lengthwise and the bottom is already firmly glued, the top cover can be glued very accurately

4. What Is cardboard packaging used for?

Cardboard packaging is incredibly versatile and offers a fantastic range of uses. The main purpose of cardboard packaging is to protect the goods (usually solid items) that need to be stored and transported.

This is a broad way of looking at cardboard packaging because the reality is that cardboard can be used to store everything from electronics to household items. Companies use cardboard boxes to ship products in bulk, while businesses pack orders in cardboard boxes to ensure that the goods reach customers intact. Cardboard can be used to store food and drink (e.g. cartons), and in specific cases, it can even be used to carry dangerous chemicals, medicines, and hazardous waste.

The list goes on and on – individuals, small businesses and large industrial companies use cardboard boxes.

If an item needs to be shipped, it probably can be shipped in a cardboard box!

5. What are the drawbacks of cardboard for packaging?

Of course, nothing is perfect. Sometimes one carton doesn’t fit all your packaging needs and you have to look for other options.

Perhaps the biggest disadvantage of cardboard boxes is that they are not designed for shipping. Sometimes, carton packaging works well with your shipping and fulfillment needs, but please note that cartons are not intended as self-contained or strong outer packaging.

The cardboard box is lightweight and easy to store. Unfortunately, to do this, they have to sacrifice some power. The maximum thickness of cartons is usually 0.032 inches (0.81 mm), so they can only hold a few pounds at most.

The folded carton is strong enough to stand on a shelf, but if you toss the carton in the mail, it might not be so good. Cartons are usually meant for retail display, not clanking in the back of a delivery truck.

Most companies cannot rely solely on cardboard boxes for their shipments. Carton boxes can hold individual products, but suppliers will need to choose something sturdier for shipping from the manufacturer to the store shelf.

6. What are the suggestions for choosing a cardboard packaging machine supplier?

Here are four suggestions:

1) Know your suppliers

When you approach a machine supplier, be prepared to ask as many questions as possible. You should know their distributors, team, and sales reps. Remember, buying a cardboard box packer is not a once-in-a-lifetime event. This is an ongoing process that includes the stages of purchase, maintenance, repair, and replacement. In order to experience a smooth workflow, you should have a good time with your dealer.

Investigate more about the vendor’s experience, nature, and mission. understand these factors

Helps you decide if a supplier is a pleasure to work with.

2) Visit them

It is difficult, or rather impossible to buy a cardboard packaging machine without visiting a supplier.

That’s why you should choose a company that works in your area. Never settle on a dealer over the internet or over the phone. Call them and stop by their office. These visits will help you learn more about their customer service and reputation.

3) The right product

As mentioned earlier, cardboard packaging machines require a wide range of machines. It is important to choose a supplier that offers a large selection. They must have interesting products

Wire. Also, they should have reliable brands to choose from. Always exclude suppliers that do not use state-of-the-art technology. Don’t choose a vendor that sticks to old, outdated methods. On the contrary, companies with newer equipment, better functions, and complete automation functions should be selected.

4) Talk about the service

What do you do when your machine stops working? Always discuss repair and maintenance issues with your supplier. Learn more about their service packages. If they don’t offer full service, stay away from them! Service (alias maintenance) should be part of the initial price negotiation.

Repairs are very important because a faulty machine can bring your productivity to a halt. And, when production stops, your paperboard packaging business won’t see any profit.

7. Conclusion

This is the Carton Packing Machine. I hope this information will be of assistance to you.

Leave A Comment