Welcome to this article, which is an in-depth guide to paper feeding machine, and if you’re looking for any information about paper feeding machine, you’ll find it here. So read on to learn more.

1. What is a paper feeding machine?

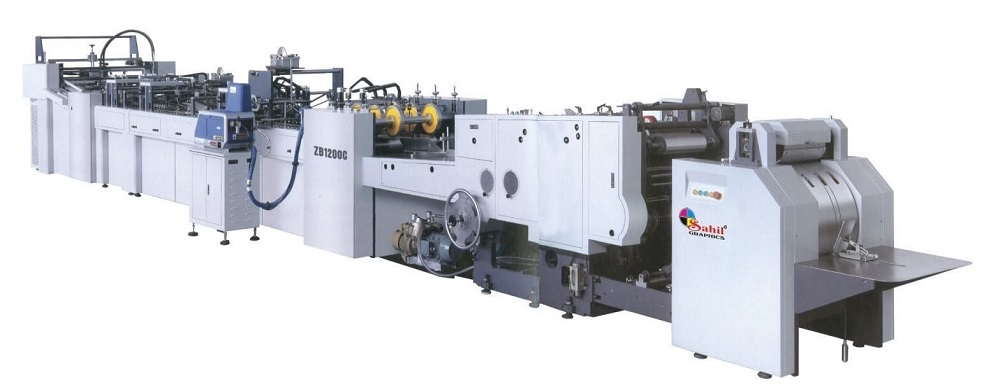

The paper feeding machine itself is a machine that helps the production process to run effectively and efficiently. The working principle of the paper-feeding machine is to send out the paper or objects one by one, and then convey them back by the belt conveyor.

When printing cartons, many carton factories traditionally use chains to feed paper, but forming machines cannot achieve continuous mass production. This paper-feeding device will continuously feed paper, and traditionally people only feed one paper at a time. In addition, this product is able to keep the corrugated board moving on the right track. It can not only improve work efficiency but also significantly reduce labor intensity and scrap rate.

2. What is the operation of the paper feeding machine?

A stack of paper is deposited by a powered preload conveyor. The conveyor incorporates a tailgate so the stack can be positioned squarely before individual chain-driven rollers transport the stack onto a 12,000-pound-capacity lift table. The lifting platform is a continuously working hydraulic oil pumping platform, which automatically maintains a constant oil pipe height through photoelectric cells. When the stack of paper is raised to the predetermined line height, a cylinder lowers a vacuum head, so that the four vacuum cups touch the uppermost paper.

The vacuum cups lift the trailing edge of each board, which activates a second air cylinder to provide horizontal motion and push the board into a set of feed rollers. As the sheet moves onto the feed roller, the vacuum automatically shuts off on the cup, releasing the sheet. Air separator and a flexible roller to ensure single-sheet feeding. As the sheet moves through the feed rollers, a sensor mounted on the back of the feed rollers sends a signal to the vacuum head to feed the next panel. This machine can load 15 boards per minute.

When a stack is complete, a switch built into the lift table is activated and the lift table is automatically lowered, ready to accept a new stack. Sheet feeders are just one of many different types of vacuum sheet feeders.

3. What are the characteristics of the paper feeding machine?

It has the following characteristics:

- The automatic suction cup feeder is combined with testing equipment, cutting equipment, packaging equipment, etc. to realize the automatic feeding function.

- The paper-feeding machine adopts a PLC control system. Feed paper according to the signal of the main equipment, the operation is stable and reliable, and the paper feeding speed is the fastest, 2 seconds per sheet.

- When the paper feeding fails, the equipment stops automatically and outputs a failure signal to the main equipment system. There is an emergency stop switch on the equipment, and the operation panel can directly deal with faults such as paper jams.

- The device adopts 220v voltage and has a built-in vacuum pump to meet the separation requirements of paper, and the paper supply works by itself.

- This equipment is suitable for 90 ~ 500g paper, and the paper does not need to be adjusted and replaced. It is convenient to adjust the size of different papers and adjust the position of a marking scale.

- The tray of the paper loading station automatically raises the paper, and the maximum paper thickness is 52CM.

- The equipment can be equipped with a small amount of paper alarm function; it can be configured to work normally when changing paper and has the function of adding paper without stopping and adding straight paper without stopping the machine.

4. What are the benefits of the paper feeding machine?

Our paper-feeding machine has the following advantages:

- The automatic feeding device system

- Simple, easy-to-operate models.

- The feeding speed is adjustable.

- Product size can be adjusted according to your needs.

- Can be integrated into other machines such as labeling machines, folding, and injection printing.

- Easy to clean and lasts a long time.

- Made of all stainless steel, the machine is rust-proof and more solid in use.

- Friction pagination

- Energy saving

- Long-lasting

- Vacuum adsorption

- Low noise

- High precision

- High scalability

- High-security level

- Competitive price

- High reliability

- Automation

- Sustainable Development

- High productivity

- Multifunction

- Double inspection

5. What are the two types of paper feeding machines?

There are two main types of paper feeding machines. Continuous feed and friction feed are two types of paper-feeding machines.

6. Which industries are paper feeding machines suitable for?

The pharmaceutical industry, printing industry, packaging industry, food industry, cosmetics industry, seed industry, the pesticide industry

7. Conclusion

The paper feeding machine is an efficient and necessary equipment machine that can save costs and increase production. The above is the whole introduction about the paper feeding machine, I hope you can read this article

Leave A Comment