Welcome to this article, which is an in-depth guide to box packing machine, and if you’re looking for any information about box packing machine, you’ll find it here. So read on to learn more.

1. What is a box packing machine?

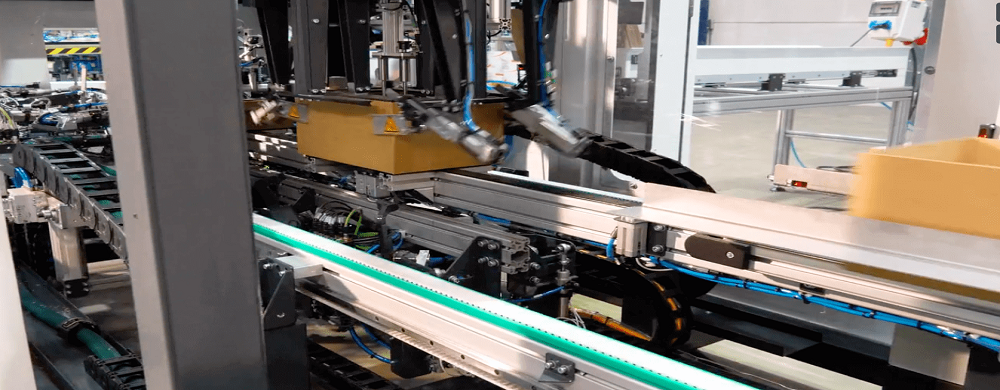

A box packing machine is a device that semi-automatically or automatically packs unpacked products or small packaged products into transport packages. Its working principle is to pack the products into cartons (corrugated boxes, plastic boxes) according to a certain arrangement and quantity, and close or seal the opening of the box. According to the requirements of the carton packaging machine, it should have the functions of carton forming (or unpacking), metering, packaging, etc., and some are also equipped with sealing or binding functions.

2. What are the characteristics of a box packaging machine?

There are some characteristics below:

- It can automatically sort and arrange products according to packaging requirements.

- Novel design and compact structure.

- A wide range of applications can be used for the packaging of various products.

- Especially suitable for matching with packing line, easy to move.

- Computer program control, simple operation, stable action.

3. What is the function of the box packing machine?

The box packaging machine can operate small boxes (such as food and medicine packaging boxes), glass bottles, plastic bottles, plastic barrels, metal cans, flexible packaging bags, and other packaging forms. The basic requirement is the process of being able to take box boards → box forming → bottom folding → carton transfer → product collection and packaging. In the actual operation process, take out the box plate, form the box, and cover the back in sequence, so as to complete the form box. After the rigid packages such as bottles and cans are collected and sorted, the gripper of the carton machine grabs a certain amount, and then directly puts them into cartons, plastic boxes, or pallets. If the carton has partitions, the packaging accuracy of the camera is required to be higher. The packaging of flexible packaging products generally adopts the method of forming boxes, receiving materials, and filling at the same time, which can increase the packaging speed. The automatic box packaging machine is equipped with auxiliary equipment such as box sealing and bundling, which automatically seals and bundles the boxes to complete the final process.

4. What is the principle of a box packing machine?

The box packaging machine can automatically form and arrange the packaging, put it into the opened carton, and complete the self-adhesive sealing and other packaging equipment. All actions are fully automatic. Most automatic case packing machines adopt a new type of combined structure, including functional units such as packing case forming device, centering device, filling device, packing case sealing device, etc., which respectively complete the corresponding functional actions and each device is installed on the same host on the shelf.

The box blank frame of the box-forming device is above, the filling device is directly below the box-forming device, the alignment device is in front of the filling device, and the box sealing device is behind the filling device. Adopt PLC + touch screen control. It is equipped with an alarm stop for lack of bottles, and a safety device for no bottles and no packaging. It greatly facilitates operation and management, reduces production personnel and labor intensity, and is indispensable equipment for automated mass production.

5. What are the parts of the box packing machine?

There are mainly belt conveyors, separation devices, centering devices, gap conveying and filling devices, box forming, and glue spraying devices.

1) Belt conveyor

It consists of two flat belt conveyors (A, B), the inlet of which is connected to the previous process, and the other end is input with workpieces.

2) Separation device

Including separation frame assembly, upper belt assembly, lower belt assembly, upper transition roller assembly, lower transition roller assembly, width adjustment assembly, height adjustment assembly, wherein the width adjustment assembly is fixed at the bottom of the separation device frame assembly, and other components are fixed at the separation side panels of the shelf assembly.

3) Arrangement device

Including transmission and frame assembly, small trough assembly, pushing surface moving assembly, guide mechanism assembly, small trough assembly, pushing surface moving assembly, and guiding mechanism assembly are respectively installed on the frame assembly of the centering device; the alignment device and The gap conveying and filling device is connected.

4) Gap conveying and filling device

It includes a frame assembly and a conveying drive assembly, and the conveying drive assembly is fixed on the frame assembly.

5) Forming glue spraying device on the packing box machine

Including carton blank frame, lower carton assembly, filling door assembly, conveying frame assembly, top folding body assembly, sealing assembly, and conveying drive assembly.

Each component in the box body forming and glue spraying device is respectively fixed on the frame component.

6. What is the type of box packing machine?

A packing box machine is a kind of machine used for product sales packaging. It packs a certain amount of material into a box and closes or seals the opening of the box. Both the carton machine and the carton machine have the functions of forming (or unpacking), measuring, filling, and sealing. The classification of carton machines includes carton machines, carton machines, soft bag carton machines, fully automatic carton machines, semi-automatic carton machines, and fully automatic carton machines for pillow bags.

7. How to choose a box packing machine?

The choice of carton packaging machine can generally be considered from the following aspects:

1) Mechanical structure

The collection, sorting, and clustering of products are the key to the packaging machine, so users should pay attention to whether the mechanical structure of the packaging machine can meet the user’s production needs before purchasing. In addition, according to the different packaging methods of the product, there are generally four packaging methods: grabbing, clamping, sucking and pushing. Users should choose the best packaging method according to their needs before purchasing.

2) Automatic control

The control system is the guarantee for the normal operation of all functions, and it is also the automatic protection for faults and accidents, so the user should know in detail how the control system is set up when choosing.

3) Production speed

Whether it can meet the production requirements.

4) Internal configuration

Only a good configuration can guarantee a good product, so users should pay attention to whether the internal configuration of the packaging machine has selected better quality accessories when purchasing a packaging box.

8. What are the precautions for using the packaging machine?

For cartons packed by automatic packaging equipment, the following issues should generally be paid attention to:

1) The crimping line should be clear, and the crimping line and slotting position should be accurate

Different from manual packaging, automatic packaging equipment has relatively high requirements for crimping and slotting cartons. In the process of manual packaging, it is possible to manually correct the unfavorable factors that affect the natural formation of the carton, such as shallow indentation, indentation, slotting, etc.

The automatic packaging is mainly completed by the cooperation of the suction nozzle, the blocking rod, and the clamping rod, and does not have the function of forming correction. Therefore, when processing cartons, it is necessary to ensure that the indentation of the carton is clear, and when the carton is folded, it must be easy to bend, so that there will be no defects such as broken lines and crow’s feet. In addition, the accuracy of grooving and crimping must be guaranteed. Generally, the slotting or blanking movement does not exceed 2mm.

In order to facilitate the upright formation of cartons by automatic packaging devices, some foreign carton machinery manufacturers have recently introduced a process called pre-folding. The pre-folding process is to install a pre-folding device on the automatic gluer to pre-fold the first and third crease lines of the cardboard once. Doing so reduces the resistance to refolding on the crimp line, making it easier for automated packaging lines to erect the cartons.

2) The hole in the corner of the box should not be too large

Generally, automatic box packing machines have two sealing methods: glue sealing and tape sealing. Unlike the manual “I” sealing method, neither the rubber seal nor the tape seal will seal the four corners of the box. If the hole in the corner of the box is too large, it will weaken the waterproof and moisture-proof function of the carton. Especially for some export goods, most of them are transported to the delivery place through containers. During sea transportation, the air humidity in the container may be as high as 93%. wet. In general, for self-sealing cartons, the diameter of the box corner hole should not exceed 5mm.

Leave A Comment