Before you buy a new cardboard die cutter, check out our guide covering everything you should consider in order to find the best machine for you.

1. What is a cardboard die-cutting machine?

A cardboard die-cutting machine is used to die-cut out different shapes of cardboard or boxes. Die cutters use a combination of rollers and cutting plates to apply pressure to a die and push it through the cardboard or paper to create neatly contoured, precise shapes—called die cuts.

2. Why do you need a cardboard die-cutting machine?

Packaging has been an important issue for all types of businesses for many years, mainly because it is the primary means of ensuring the safety of products once they are shipped. For this reason, companies have long sought to create packaging that is strong, reliable, precise in form and function, and most importantly, affordable. One of the most efficient ways to make cardboard is to use die-cut forms.

Die-cutting allows obtaining extremely complex parts not normally possible with scissors or a box knife.

Die-cut cardboard is highly customizable corrugated cardboard boxes designed to fit any shape, size, or need. Since fully custom boxes are usually a little more expensive than standard-sized and shaped boxes, it’s a little counterintuitive to think that they could actually save your company money. However, when you consider the big picture, die-cut cardboard can save you a ton of money.

Die-cut cardboard is shaped to fit your product better than a standard shipping box. Not only does this minimize wasted space during shipping, but it also eliminates the need to additionally wrap the product – like bubble wrap peanuts to fill the extra space; This is another factor that can help save you money.

3. What are the advantages of a cardboard die cutting machine?

Die-cut forms offer many advantages over traditional cardboard-making methods. Here are some benefits of die-cut forms:

1) Accuracy

When precision cutting is required, there is no other method like die-cut forms. Die-cutting ensures that each box is properly formed, contributing to its overall stability and overall durability. It also helps reduce material waste by ensuring that only a preset amount is removed in a designated area with each cut.

2) Efficiency

The die-cut format can also cut large stacks of cardboard in one go, which can cut the work done in half and increase output by up to ten times. This makes it possible to produce a large number of boxes in a short period of time without having to sacrifice uniformity or durability.

3) Convenience

As companies are always looking for more efficient ways to save money, die-cutting forms eliminate manual labor, not all, but at least the minimum, as it is fully automated and can be programmed to perform any easier simple or repetitive tasks sex task. Most of the quality control is left to a selected number of workers who inspect and form the final product and are responsible for maintaining the machines.

4. What are the disadvantages of cardboard die cutting machines?

Cardboard die-cutting machines have the following disadvantages:

1) Inaccurate cutting

A common die-cutting problem today is increasing inaccuracy when cutting cardboard and cartons. Some cardboard templates can get complicated. Due to the increased complexity of the die-cutting process, the cutting accuracy of packaged products can be significantly affected. Due to the margin of error exceeding the recommended limits, the appearance of the board is expected to be non-uniform and precise. Fortunately, this problem can be avoided with the correct choice of die cutting tools.

2) mediocre cut

The die-cutting process can also produce poor-quality cardboard and boxes if the operator does not employ the correct preparation methods. During this process, it is necessary to gradually increase the pressure on the knife to make the product thinner. A mediocre cut can likewise be avoided if the blade is aligned effectively. Finally, the quality of materials and cutting tools must be thoroughly checked in order to effectively maintain the results of the die-cutting process.

3) Wrong indentation line

Most cardboard has creases so it can be folded and glued. But for indentation lines to be effective, they must be properly positioned and applied to the workpiece. They also work if the crease lines have the correct height and width. Failure to meet these requirements will simply result in poor creasing lines for cartons and boxes, making it difficult for the industry to fold them accordingly and use them efficiently.

4) Uncut product

Die cutting tools may be able to cut a variety of materials. But if the workpiece becomes too thick, the tool may have difficulty cutting all of it. Even if some of these materials are cut, they may bear some noticeable marks due to sudden warping and denting of the blade. Once the blades become deformed or dented, the industry may be forced to stop operations, replace them, and regain access to new workpieces. Doing so can be costly, which is why these elements must be checked efficiently.

5. What is the working principle of the cardboard die cutting machine?

The working principle of the cardboard die-cutting machine is to use a steel knife, a metal mold, and a steel wire (or a template carved from a steel plate) to apply a certain pressure through the embossing plate, and die-cut the printed matter of the cardboard into a certain shape.

If the entire printed matter is pressed into a single graphic product, it is called die-cutting;

If a wire is used to mark a mark or leave a curved groove on a printed matter, it is called an indentation;

For example, if two yin and yang templates are used, by heating the mold to a certain temperature, a pattern or font with a three-dimensional effect is hot stamped on the surface of the printed product that is called hot stamping;

If one substrate is laminated on top of another, it is called lamination;

The rest except genuine products are called waste disposal;

6. What are the types of cardboard die cutting machines?

Here are some cardboard die-cut types:

1) Rotary die-cutting machine (suitable for thicker corrugated cardboard)

A rotary die cutter has a cylindrical anvil and a die made from a single piece of tool steel. As the sheet passes through the machine, a series of quick and accurate cuts modify the metal. This process is best for high-volume projects or “kiss-cutting,” where the perforations must go through the material without piercing to make the lining. In high-volume production, rotary die-cutters can increase productivity while reducing material waste. The machine is ideal for precision cutting with low tolerances and can also be combined with other processes.

2) Cover Die Cutting Machine

The pressure clamshell die-cutting machine usually has a knife die, which is fixed at the position where the motor drives the pressure plate into the mold, and the mechanism opens and closes like a clamshell. The cutting action of the mold can be controlled by electric, hydraulic, pressurized, or manual. Depending on the application, the die can cut and form a single piece of material, or the material can be stacked to produce multiple copies simultaneously.

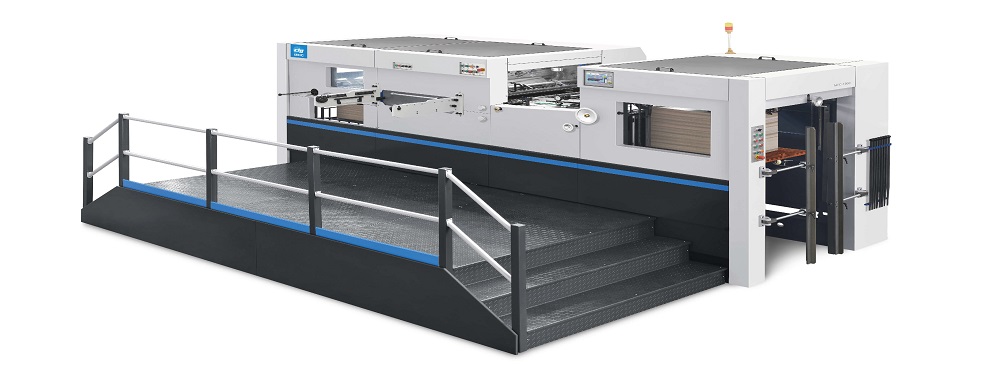

3) Automatic flat die cutting

Flat die cutters use varying degrees of hydraulic pressure to stamp shapes with steel ruler dies. These machines are very effective for precision cutting, halves, and die cutting of sheets and laminate. Benefits of flat die cutting include lower tooling costs, wider tolerances for materials thicker than 1/8 inch, and high design flexibility. Flat die cutters are ideal for small batch orders, projects involving many different shapes, or bending applications that don’t require the material to be very efficient.

7. What is the purpose of the cardboard die-cutting machine?

The cardboard machine mainly cuts flexible materials such as cardboard, self-adhesive paper, coated paper, plastic board, and PVC board. It is mainly used for die-cutting, creasing, and cold pressing of trademarks, cartons, and greeting cards in the paper packaging industry. It is an important piece of equipment for post-press packaging processing. Die-cutting machines are not only used to facilitate transportation, but also to attract consumers’ purchase needs, and their market share has increased accordingly. They ensure maximum productivity during die-cutting.

8. What are the maintenance tips for the cardboard die-cutting machine?

Here are some tips:

1) cleaning

Empty the chamber of the die cutter, clean the cylinders, and remove any debris. As paper or cardboard is moved from one station to another, paper fibers can become lodged in the hardware. If they pile up, they may displace the paper in the die-cutter. The slightest change in angle or position can affect the accuracy of cuts, folds and creases, so keeping your die cutter clean inside and out is critical.

2) Hardware detection

Regular inspection of the machine’s loose and connected parts can prevent equipment damage. In addition to debris buildup, look out for blunt burrs, loose wheels and fasteners, worn belts, broken rubber parts, and any damaged or missing parts.

3) Alignment, recalibration, and troubleshooting

A short calibration test between work days will ensure your die cutter is in top condition for the days you put it into work. Here are some things to check:

Replace worn timing belts, anvil springs, and other parts prone to rapid aging.

Check the precision of dies, guide posts, creasing, and folding stations.

Check that you are using enough spacers (card stock inserts are used to reduce the chute gap and raise the paper so the die can cut it properly).

Review the settings and instructions programmed into the machine, namely depth of cut and pad impact.

Run QA tasks and check for recurring defects such as piercing breaks.

Check the burr height and clearance ratio (pro tip: increasing punch-to-substrate clearance increases hole size, reduces stripping friction, and increases overall tool life).

4) Pressure and heat check

Die cutters heat up as they operate. Measure and record the pressure and peak temperature of the machine and note anomalies. They usually indicate electrical and hardware problems.

Leave A Comment