Welcome to this article, which is an in-depth guide to printing houses, If you’re looking for any information about printing houses, you will find it right here. So keep reading to learn more.

1. What is a printing house?

Printing is a technology in which text, pictures, and other original documents are transferred to the surface of paper, fabrics, leather, and other materials through the process of plate making, ink application, pressure, and other processes, and the content of the original manuscript is copied in batches. There are many forms of printing, which can be divided into traditional offset printing, screen printing, digital printing, etc. Hole printing, letterpress printing, gravure printing, and lithographic printing are also known as the four major printing technologies of modern times. The printing house is a comprehensive institution integrating design, proofing, plate making, printing, binding, packaging, and transportation. Of course, the most important thing is that the printing house must have printing equipment to be called a printing house, and the printing machine is the most important, some simple printing can also be printed with a screen print, only a screen can be completed printing, but the effect is not better than the printing of the large machine.

2. What is the basic introduction of a printing house?

The printing house must have printing equipment to be called a printing house, and the printing machine is the most important, the printing machine has a single color, two colors, four colors, etc., according to the specifications of 8 boots, 4 starts, double start, and full boot, etc., some simple printing machine can also be used for screen printing, only a screen can complete printing, but the effect is not better than large machine printing.

Larger printing plants will also have some other printing equipment, such as glue machines, carbonless copy bill printing machines, automatic die cutting machines, high-speed folder-gluers, etc., and add a hair room, a laser knife mold room, and a binding paste workshop. There are also small printing, such as screen printing, which can be printed with only a screen, but the effect is not as good as large-scale printing.

3. What is the operating scope of the printing house?

Printing houses can do a lot of things, such as promotional brochures, samples, books, newspapers, magazines, bills, cartons, cartons, paper pockets, wall calendars, desk calendars, envelopes, rolls, books, posters, etc. In short, printed products can be seen everywhere in our life and work, and because of this, there will be printing technology exchanges, printing recruitment, printing publicity, printing exhibition activities, etc.

The technology of transferring the ink to the surface of paper, fabrics, leather, and other materials through the process of plate making, inking, pressurization, etc., and batch copying of the original content is called printing. There are many forms of printing, divided into traditional offset printing, screen printing, digital printing, etc.

Screen printing is a mainly manual operation and is mainly used for PET label printing. Generally, printing plants based on printing electronic labels are generally equipped with web screen printing machines. In addition, web flat flattening die-cutting machines and small slitting machines are also necessary equipment for such manufacturers.

In the national standard “Printing Technical Terms”, the definition of printing is the process technology of using printing plates or other means to transfer the graphic information on the original document to the substrate.

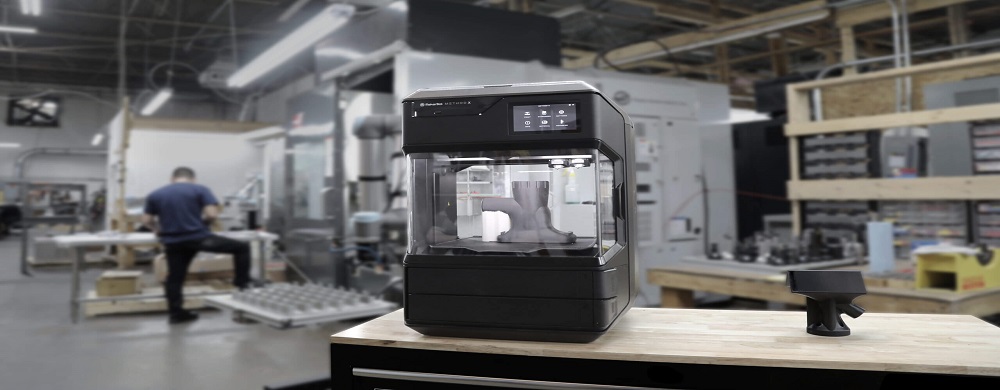

4. What equipment does a printing house need?

The printing machine is the most important type of printing production machine. Among them, the printing machine has single-color, two-color, four-color, and eight-color, according to the specifications are divided into 8 starts, 4 starts, half open, and full start.

In addition to the printing machine, there is some printing processing equipment that also needs to be spared, including glue binding machine, carbonless copy bill printing machine, automatic die cutting machine, high-speed folder-gluer, etc., and at the same time, there is also an operation room such as a hair room, a laser knife mold room, and a binding and pasting workshop. These printing production conditions are the production conditions that regular printing plants should have.

5. What formats are available for the printing business?

Different types of printing businesses have different usages. And, it mainly includes the following four types of printing: Self-adhesive printing, label printing, sticker printing, label printing, etc. (Mainly matt paper materials, such as thermal paper, heat transfer paper, matt paper with (or without coating) and a small amount of coated paper, mirror coated paper.) The film is mainly sub-silver PET material, and a small amount of BOPP, PVC, etc. )

- Packaging printing: such as book printing, news printing, advertising printing, and letterpress rotary machine printing. The printing of books and magazines used to use letterpress printing. News printing, which used to be printed by letterpress rotary machines, was also printed in large quantities because of its speed and large print volume. Recently, in order to adapt to the needs of color, lithographic or photographic gravure rotary printing was used.

- Advertising (inkjet) printing: including color pictures, pictorials, posters, etc., most of them are used lithographic printing, and occasionally letterpress, gravure, or hole printing is also used.

- Stationery printing: such as envelopes, stationery, invitations, business cards, account books, workbooks, etc., the price of a large amount of printing work will be cheaper.

6. What is the workflow of a printing house?

- Customers consult online or hotline

- Professional business personnel to communicate door-to-door

- Sign the printing and processing contract and pay the advance payment

- The preliminary graphic design

- Customer proofreading and modification

- The customer’s final signature is finalized

- Publish the film, proof it, and then let the customer review the final draft

- Imposition, resin version, or PS version

- Machine printing

- Post-processing

- Binding (glue, hardcover, horseback binding, flat binding, simple binding, adhesive finish)

- Fold (two, three, four, five, etc.)

- Coating (bright film, matte film), varnishing, oiling (partial, all), UV (partial, all)

- An ordinary cutting (right angle, rounded corner, circle, oval), special-shaped cutting, hot stamping (gold, silver), convexity

- Mounting (envelopes, tote bags, packaging boxes, hardcover book covers, card boxes)

- Inspection of finished products

- Finished product packaging and transportation door-to-door.

7. How to open a printing house?

There are some steps below:

1)Invest in the establishment of a printing house business

If you have land where you can set up your printing machinery, you’ve saved some huge investments, but beyond that, it’s clear that capital is required to start any type of business.

Some of the big investments in this business are the purchase of equipment and machinery. Depending on the size of this paper plant you have to start, you need to invest accordingly. Other investment terms, including building factories, labor, transportation units, etc., are discussed below.

2) Registration

Registering a business name is essential for every business in any country. You will earn money from this paper printing house, and according to the rules of your country, you will need to pay income tax. The business registration process can take up to 1 month, depending on the laws of your country of residence. You need to comply with all legal formalities and obtain approval from an authorized person.

3) Purchase the machine

Purchase the required machine from an authorized seller in your country. There are many machines available, and the price of each machine depends on the production capacity.

If you’re willing to start with a small printing house, they have a lower production capacity compared to heavy-duty high-output units. You can also import machines from China, from where you can get the best deals on small machines. Visit two or three suppliers in your city and compare prices, then make a decision based on your budget.

4) Hire employees

You will need labor to operate the machines and do some other tasks such as loading and transporting raw materials. Train your staff to operate paper machines correctly. In the beginning, you’ll be incurring labor costs, so make sure you use them effectively. Make experts in operating machines.

5) Paper plant raw materials

Contact a distributor in your city who supplies raw materials. The raw material comes from wood fibers from saw plants, and conifers (also known as a cork in the paper industry). Get information about raw materials for the production of strong paper. The quality of the final product will depend on the raw materials used. You need to buy all the materials you need to make paper. Upon request, you will need to order materials.

Don’t order too many materials just in case you fail to make a sale, then excess materials will be wasted. You need the help of professionals who can help you understand the demand and availability of your products. Visit several paper plants in your area and get information from there.

6) Competitor analysis

You need to understand the printing business market; You need to know your competitors. After knowing who your competitors are, you need to come up with better strategies to fend off the cutthroat competition from them. You need to innovate in the market, otherwise, you will have a hard time surviving. You need to follow an effective business plan and work accordingly.

7) Mechanical equipment analysis

Making paper is not child’s play, you need to buy large machines that can make paper of any size in less time, i.e. with high productivity. There are various machines available on the market for different purposes and to produce different types of printed products.

You need to do extensive research to understand what kind of machinery and equipment you need. After research, you need to spend money on the most suitable machine, otherwise, you will overspend and end up wasting money.

8) Promote your business

Contact your local distributor and supply them with paper. Research the pricing and offer them your products at competitive prices. After buying machines, and equipment, and hiring labor, you need to focus on advertising and marketing. Consider hiring a salesperson and giving him a percentage of every lead they bring to you, which is an important process to help you sell your products.

In addition, you need to run ads in newspapers, TV, magazines ads, and internet ads to reach plants of people across the country. You need to advertise your products in the most creative way possible to attract customers. You need to ensure the quality of each sheet to win the hearts and minds of your customers. Without advertising, you can’t achieve your goals.

7. What are the precautions for operating a printing house?

There are some precautions below:

- If working in a dark place, the workplace must have adequate lighting.

- If working in a closed container or in an air-circulation environment, workers must carefully check the rear for hazards and, if necessary, designate personnel to take care of them.

- In the workplace or machine aisle, a product must not easily slip or interfere with other objects.

- The groove cover must not be opened casually. If it needs to be opened, protective measures should be taken, and it should be covered immediately, and the pit pool and trail should have a fence or cover plate.

- For dangerous places, warning signs must be hung and no random approach or warning places are allowed.

- Smoking is prohibited in the factory to avoid fire.

- The oil part is flammable and must not be in the working atmosphere or cooking to avoid slipping or catching fire.

- If the machine stops inspecting, workers must hang a warning sign at the switch and contact an electrician to turn off the power at the same time.

- During equipment maintenance, all machines must be thoroughly inspected to see if the individual parts of the equipment are completed according to the provisions of the start-up steps, and then start production.

- Do not touch or repair running machines.

- There are no protective devices for rotating equipment, and little work from above, near, or in hazardous areas.

- Do not use inert force to stop until the machine is ready to stop.

- Do not throw transfer tools or materials.

- The loading and unloading of the rotating belt must be stopped and the belt oil applied to the belt in the direction of transmission.

- It is necessary to check the tool to be used in advance.

- The drum, gears, and rotation at the entrance of the machine are the most dangerous, and contact near the entrance is not allowed.

- A switching gate must stand on one side of the gate and open slowly.

- Do not put water on electrical equipment.

- Wet hands and wet bodies may not allow the operation of electrical equipment.

8. What is the trend of printing houses?

Since 2020, printing companies are in an unprecedented period of change, with gradually reducing unit volume, increasing quality requirements, and low unit prices. So this is undoubtedly a wake-up call for traditional printing houses. If printing companies want to survive the fittest in this change, they must fundamentally improve the status quo within the enterprise, and achieve the purpose of enterprise open source and cost reduction with process standardization, management standardization, information intelligence, and channel diversification.

Leave A Comment