Welcome to this article, which is an in-depth guide to paper plant, If you’re looking for any information about a paper plant, you will find it right here. So keep reading to learn more.

1. What is a paper plant?

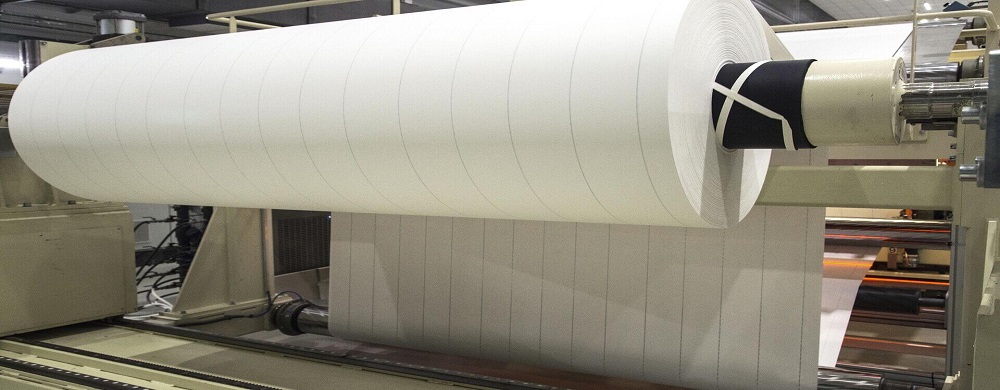

A paper plant is a plant that produces paper through a mechanical assembly line. Paper-making can be divided into mechanical and manual forms. The mechanism is carried out continuously on a paper machine. Dilute the pulp suitable for paper quality with water to a certain concentration. The net part of the paper machine is initially de-watered to form wet sheets, which are then dehydrated by pressing and dried into paper. Frames with bamboo curtains, polyester mesh, or copper mesh are used by hand.

2. What equipment does a paper plant need and how much does it cost?

The basic equipment required for a paper plant includes transformers, steam pipes or boilers, water intake equipment (surface water such as groundwater or rivers), sewage treatment equipment, etc. In addition, paper machines, pulping equipment, damaged paper-making equipment, pulping pumps, water pumps, workshops, pulping pools, etc. are also needed.

For example, pulping machinery and the whole paper-making machinery include mesh folding part, pressing part, drying dry section and paper machine, rewinder and some need sizing machine, etc.

According to the needs of the pulp and the production of different types of machines are also different, the raw material is environmentally friendly imported wood pulp. The price of the equipment is determined by your requirements, if you take a small paper equipment investment of 100,000-200,000, your factory can mainly produce toilet paper and burning paper. First of all, you have to have a production line. Regular equipment is estimated to be not tens of plantations of dollars. Used or small should be cheaper.

Secondly, sewage treatment facilities. At present, under the strict monitoring of national environmental protection, it is not very realistic to have no sewage treatment.

Then, all kinds of accessories, and facilities are needed.

Finally, wood chip raw materials are supplied. Usually, many people want to open a pulp plant, the first thing is that they have a lot of wood chips available.

Due to the different sizes of various types of pulp plants, the demand for investment gap is quite large. Large ones often cost billions, and medium-sized ones also need more than 100 plantation funds. In general, tens of plantations are always needed.

3. How to start a paper plant business?

There are some steps about start a paper plant business below:

1) Invest in the establishment of a paper plant business

If you have land where you can set up your papermaking machinery, you’ve saved some huge investments, but beyond that, it’s clear that capital is required to start any type of business.

Some of the big investments in this business are the purchase of equipment and machinery. Depending on the size of this paper plant you have to start, you need to invest accordingly. Other investment terms, including building factories, labor, transportation units, etc., are discussed below.

2) Registration

Registering a business name is essential for every business in any country. You will earn money from this paper plant, and according to the rules of your country, you will need to pay income tax. The business registration process can take up to 1 month, depending on the laws of your country of residence. You need to comply with all legal formalities and obtain approval from an authorized person.

3) Purchase the machine

Purchase the required machine from an authorized seller in your country. There are many machines available, and the price of each machine depends on the production capacity.

If you’re willing to start with a small paper plant, they have a lower production capacity compared to heavy-duty high-output units. You can also import machines from China, from where you can get the best deals on small machines. Visit two or three suppliers in your city and compare prices, then make a decision based on your budget.

4) Hire employees

You will need labor to operate the machines and do some other tasks such as loading and transporting raw materials. Train your staff to operate paper machines correctly. In the beginning, you’ll be incurring labor costs, so make sure you use them effectively. Make experts in operating machines.

5) Paper plant raw materials

Contact a distributor in your city who supplies raw materials. The raw material comes from wood fibers from plants, and conifers (also known as a cork in the paper industry). Get information about raw materials for the production of strong paper. The quality of the final product will depend on the raw materials used. You need to buy all the materials you need to make paper. Upon request, you will need to order materials.

Don’t order too many materials just in case you fail to make a sale, then excess materials will be wasted. You need the help of professionals who can help you understand the demand and availability of your products. Visit several paper plants in your area and get information from there.

6) Competitor analysis

You need to understand the paper business market; You need to know your competitors. After knowing who your competitors are, you need to come up with better strategies to fend off the cutthroat competition from them. You need to innovate in the market, otherwise, you will have a hard time surviving. You need to follow an effective business plan and work accordingly.

7) Mechanical equipment analysis

Making paper is not child’s play, you need to buy large machines that can make paper of any size in less time, i.e. with high productivity. There are various machines available on the market for different purposes and to produce different types of paper.

You need to do extensive research to understand what kind of machinery and equipment you need. After research, you need to spend money on the most suitable machine, otherwise, you will overspend and end up wasting money.

8) Promote your business

Contact your local distributor and supply them with paper. Research the pricing and offer them your products at competitive prices. After buying machines, and equipment, and hiring labor, you need to focus on advertising and marketing. Consider hiring a salesperson and giving him a percentage of every lead they bring to you, which is an important process to help you sell your products.

In addition, you need to run ads in newspapers, TV, magazines ads, and the internet ads to reach the plantations of people across the country. You need to advertise your products in the most creative way possible to attract customers. You need to ensure the quality of each sheet to win the hearts and minds of your customers. Without advertising, you can’t achieve your goals.

9) Transport vehicles

Once you start a paper business, then the next step will be distribution. You need to arrange for the paper to be shipped to buyers who want to buy paper from you in bulk. You need to supply paper to any distance to survive in the market. You should never ignore any order. You need to fulfill every order, regardless of quantity.

Consistently meeting your goals and meeting your customers’ needs, a timely supply of inventory can help you survive in the market. You need to know your competitors and you should always be one step ahead of your competitors. You should never forget that quality is the ultimate weapon to survive in the market. If the paper you manufacture is of poor quality, then you will be overlooked and you will not be able to sell what you want.

4. What factors should you consider before starting a paper plant?

Paper machine hazards

Many hazards are common around paper machines. Knowing the types of hazards will help you identify, control, and/or avoid harm caused by specific instances of each hazard.

We will list some of the most common.

- Pinch points

A pinch point is a place where the device moves to grab or crush a person or body part.

Pinch hazards can be identified:

- Between moving machine parts

- Between moving and stationary parts

- Around or under goods being transported or lifted

- Between the mobile device and other machinery or objects

It is common practice to install single-point or barrier guards, or other engineering measures, to prevent pinch-point injuries. Identifying, properly reporting, and addressing potential hazards should be an ongoing effort for all employees.

- Pressure zone

A pinch point is a pinch point that is usually associated with adjacent rotary rollers, moving ropes or nets (such as fabric or paper), or moving ropes and rope pulleys. Pressed zones are dangerous for fingers and hands, as they often occur where material must be fed into the process or adjustment and lubrication points.

The press zone is located where two machine parts first meet and one or both parts rotate. Inward pressure openings can pull fingers, hands, hair, jewelry, and even the entire body into equipment and machinery. This can lead to serious injuries, including abrasions, amputations, and even death.

The outgoing pressure zone is also dangerous as opposed to the incoming pressure zone. If an object enters an inward pressure zone, it will be accelerated to the speed of the paper machine and become a dangerous projectile when exiting.

- Sharp surface

Sharp surfaces are objects or machine parts that can scratch, puncture, or tear the skin.

Be careful with sharp surfaces if:

Work with your hands. Hand injuries are the most common injuries associated with sharp surfaces.

Use tools with sharp designs, such as saws and knives. For example, when using a utility knife, be sure to cut it from the body.

Move the fabric on a paper machine. Touching the edges of the moving fabric can cause very serious cuts.

Handle scrapers and worn wrinkled blades. Always follow established procedures and wear all personal protective equipment required for your location.

Perform new or unfamiliar tasks. Be wary of metal burrs, protruding bolts, and sharp or rough edges.

- Hot surfaces

Hot surfaces are another common hazard in paper plants.

Machine surfaces can be hot because they are designed to generate or transfer heat, or because friction from machine movement causes them to heat up. Some potential hot surfaces on paper machines include steam lines, steam traps, pumps, and motors on forklifts.

- Chemicals

Paper facilities use a variety of chemicals, including some that are very dangerous.

You should be aware of the hazards associated with each chemical and the necessary precautions you should take when using them or near them.

It is important that all substances are properly labeled to ensure proper procedures are followed in the event of an accident. When working with chemicals, always refer to the Safety Data Sheet, formerly known as the Material Safety Data Sheet. This document provides all known hazards and safety precautions for the substance.

- Fire

Fires can be a big safety issue anywhere. The most common fire hazards in paper facilities come from breakage, litter, and dust. These materials are usually located at the drying end of the paper machine and around the rewinder in the processing area.

5. What are safe operating considerations for paper plants?

There are some tips below:

- If working in a dark place, the workplace must have adequate lighting.

- If working in a closed container or in an air-circulation environment, workers must carefully check the rear for hazards and, if necessary, designate personnel to take care of them.

- In the workplace or machine aisle, a product must not easily slip or interfere with other objects.

- The groove cover must not be opened casually. If it needs to be opened, protective measures should be taken, and it should be covered immediately, and the pit pool and trail should have a fence or cover plate.

- For dangerous places, warning signs must be hung and no random approach or warning places are allowed.

- Smoking is prohibited in the factory to avoid fire.

- The oil part is flammable and must not be in the working atmosphere or cooking to avoid slipping or catching fire.

- If the machine stops inspecting, workers must hang a warning sign at the switch and contact an electrician to turn off the power at the same time.

- During equipment maintenance, all machines must be thoroughly inspected to see if the individual parts of the equipment are completed according to the provisions of the start-up steps, and then start production.

- Do not touch or repair running machines.

- There are no protective devices for rotating equipment, working from above, near, or in hazardous areas.

- Do not use inert force to stop until the machine is ready to stop.

- Do not throw transfer tools or materials.

- The loading and unloading of the rotating belt must be stopped and the belt oil applied to the belt in the direction of transmission.

- It is necessary to check the tool to be used in advance.

- The drum, gears, and rotation at the entrance of the machine are the most dangerous, and contact near the entrance is not allowed.

- A switching gate must stand on one side of the gate and open slowly.

- Do not put water on electrical equipment.

- Wet hands and wet bodies may not allow the operation of electrical equipment.

6. How to clean sewage from a paper plant?

If you want to purify the wastewater discharged from a paper plant, you must understand the water quality characteristics of the paper plant. The COD and SS content in papermaking wastewater are high, and the color of the water is important. The concentration of SS and COD in papermaking wastewater is relatively high, while COD is composed of insoluble COD and dissolved COD. Typically, insoluble COD makes up most of the total composition of COD. When SS is removed from wastewater, most of the insoluble COD is removed at the same time. Therefore, the main problem to be solved is the removal of SS and COD.

Most SS, most insoluble COD, and some soluble COD and BOD can be removed by adding cationic polyacrylamide by air flotation or precipitation. Typical machining processes are as follows:

Wastewater is discharged → collection ponds→ air floats or sedimentation →Air flotation precipitation is a physical and chemical treatment method, and the treatment effect is related to the selected equipment, process parameters, coagulant, etc. The COD removal rate is generally higher than that of the intermediate water of pulping, usually up to 70%~85%. For small and medium-sized papermaking enterprises that discharge tons of paper wastewater > 150m3 and low concentration, after air flotation or precipitation treatment, the effluent water quality index can reach or approach the national discharge standard.

Leave A Comment