Investing in new packaging equipment is a major financial commitment that can revolutionize your business. When deciding whether packaging automation is right for your business, there are many factors to consider. ” If you are considering whether now is an ideal time to invest in packaging equipment, this article is for you.

1. Determine your packaging type

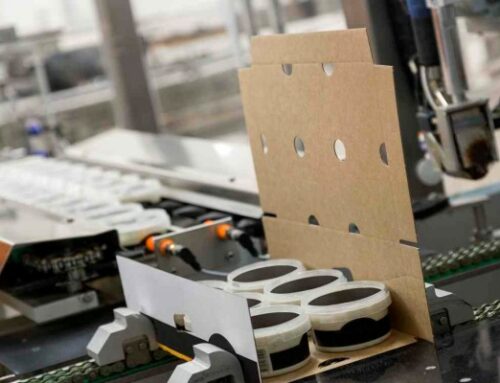

The most successful applications of automation include the standardization of goods and procedures. When your packaging is irregular, highly individual, bulky or unexpected, it can be expensive or difficult to automate the packaging process.

If your packaging falls into any of these categories, it is unlikely that you will be able to automate your packaging process. If you standardize your packaging form to one of these designs, you can automate the packaging process. However, this is only possible if your packaging is highly specialized.

Standardized packaging can be just as attractive as fully personalized packaging, while also being easier to handle and maintaining its ability to grab the attention of potential buyers on the retail shelf.

2. Consider your workforce

Many businesses believe they need to invest in packaging automation to remain competitive. If other companies in your industry have adopted automated packaging technology and you have not, you may start to fall behind. Automation of packaging requires a significant upfront investment, and it might not always be the best use of your company’s resources. If you’re not sure if packaging automation is right for your business, it’s best to consult an expert.

3. Is your business ready to invest in automation?

Let’s face it: automating the packaging process requires a hefty starting price. That really shouldn’t be the case because in this business you get exactly what you pay for. The first outlay required to purchase high-quality packaging equipment can range from five figures to millions of dollars. Also, while it’s easy to consider the price of a device, it’s also important to take a few seconds to consider the overall cost of ownership.

Do some research and calculations to determine how much it would cost you if you continued business as usual, compared to how much you expect to spend if you automate in the future. You may be pleased with how quickly it takes to recoup your original investment in packaging equipment. We’re not necessarily talking decades here. There might be months or years between us.

What’s more, once you recoup your upfront investment, your packaging equipment will continue to generate profits for you over time. On the other hand, if you decide not to automate and continue to do things manually or with inferior technology, chances are your company will slowly become less profitable over time. You might be able to get by without automation for a while, but eventually, your lack of productivity will catch up to you.

4. Weigh the pros and cons

There are many potential benefits to automating the packaging process. These include increased efficiency, reduced labor costs, reduced product damage and increased safety. There are, however, some potential downsides as well. These include high upfront investment costs, the need for specialized training, and the potential for reduced flexibility. You should carefully weigh all the pros and cons of automating your packaging process before making a decision. Only you can decide whether the benefits to your particular business outweigh the disadvantages.

5. Know how many bags you need per minute

The productivity of flexible packaging machines can vary widely, depending on a variety of factors including the product being packaged, the number of lanes available, and the program that will be used. A packaging machine suitable for your production capacity is very important. It’s important to keep in mind that your fees will vary based on the item and packaging process.

Below is a breakdown of the general productivity of our machines:

- Vertical Fill Seal (VFFS) – 30-100 bags per minute

- Horizontal flow packaging machine – 30-300 bags per minute

- Pre-made bag packaging machine – 20-80 bags per minute

Productivity can be increased by using multiple systems or more channels. If your needs fall well below these minimums, or you only intend to use the machine occasionally, you may find that a manual or semi-automatic solution is better suited to your situation. Regardless, it is important to understand your needs before deciding which packaging technology to invest in.

6. Consider the future of your business

When deciding whether to automate your packaging process, think about your business’s future.

- Are you planning to expand? If so, are your current packaging processes able to handle the increased volume?

- Are you planning to launch a new product? If so, are your current packaging processes able to accommodate this change?

It’s important to think about these things ahead of time so you can make the best decision for your business. If you are unsure about the future of your business, it is best to wait for the packaging process to be automated.

This way, you can avoid expensive investments that you may not need in the long run. In contrast, if you are confident in the future of your business, automating your packaging process may be the best option. Investing in packaging automation is a big decision. It is important to do your research and consider all factors before making your final decision.

7. Will you benefit from reduced labor costs?

Is it possible to save money on labor if I run my packaging line faster? With an automated system, you don’t need to have multiple employees working on the packaging. You might want to consider automating your packaging process if you’re looking to improve your business.

Thanks to this innovation, you will be able to ship more items and accept larger orders. If you pack and ship your goods in a timely manner, you may reduce the amount of storage space you need. You’ll also likely have fewer customer complaints or damaged merchandise. Fewer people will be handling your business, which reduces the possibility of making mistakes.

8. Do you have a product that is difficult or delicate?

If you’re packaging items that are irregularly shaped, unstable, powdery, dusty, extremely fragile, or require careful handling, you may benefit from using automated machinery. Automated machines can often do a better job than humans when it comes to these types of products.

Not only will your product be packaged more securely, but the process will be faster and more efficient. This is because automated machines can often package products faster and more precisely than humans. If your products are difficult or difficult to package, automating the packaging process could be beneficial to your business.

9. Would you like to increase the speed of your production?

You may be able to increase your production speed by automating your packaging process. Automated machines can often package products faster and more precisely than humans. This means you can increase production speed without sacrificing quality. If you need to increase your production speed, investing in packaging automation may be the best way to do it.

10. Is your packaging process custom?

In nearly every sector of the economy, customization is directly related to price increases. This will also increase costs as packaging systems become more complex. These resources include R&D, engineering, and design.

We’re not saying the investment in a custom system isn’t worth it – it is! However, higher costs must be carefully evaluated against possible future returns. In many cases, a tailored system can replace the need for manual work.

However, in order to maintain and run the system, professionals are required to monitor the operation of the packaging equipment. When you reach this stage of confusion and consideration, packaging equipment professional may help you weigh all available alternatives and investigate routine elements of the process that automation has already done.

Leave A Comment