Horizontal and vertical packaging machines are the two main types. But what is the difference between them? Let’s take a closer look.

1. What is a horizontal packaging machine?

Horizontal wrappers, also known as horizontal wrappers, are best used for easy-to-handle single solid goods such as cereal bars, soaps, small toys, bakery products, and other similar items. When using the pouch format, we are able to achieve higher efficiencies and better performance than when using stand-up packaging. This is in addition to our ability to ensure a seal.

With a strong packaging capacity, the horizontal packaging machine is a continuous packaging machine. Due to its high packing capacity, the machine is suitable for food and non-food packaging of various products.

Each horizontal packaging machine can be equipped with a robot counting and feeding system, and cartoon machine, and various selections and sorting according to customer requirements, for food, chemical, cosmetic and pharmaceutical industries.

1) Advantages of horizontal packaging machine

Some advantages of horizontal packaging machines are as follows:

#1. Accommodates a wide range of products

This horizontal packaging machine has the advantage of adapting to a wide variety of products. This is because the designs of these machines are very versatile. Therefore, they can be used to pack everything from small items to large and bulky items.

#2. High speed and high efficiency

Horizontal packaging machines are also fast and efficient. These machines can pack large quantities of items in a very short amount of time. As a result, they are ideal for applications requiring high volumes of packaging.

#3. Accurate product display

It is also possible to present products precisely with horizontal packaging machines. This means that items packed with these machines will have a very professional and polished look.

2) Disadvantages of horizontal packaging machine

Some disadvantages of horizontal packaging machines are as follows:

#1. Limited capacity

The low capacity of horizontal packaging machines is a major disadvantage. Only a limited amount of stuff can be packed at a time using these machines. Therefore, they cannot be used for bulk packaging.

#2. Not suitable for fragile items

It is not possible to package fragile items with horizontal packaging machines. The reason for this is that these machines are not designed to handle fragile items. Therefore, they can damage fragile items if not handled properly.

#3. Inconvenient horizontal bandwidth adjustment

Horizontal packaging machines are also difficult to adjust. This is because the horizontal bandwidth adjustment feature can be quite inconvenient. So if you want to make bags of various sizes on one machine, it may take a lot of time and effort to tune those machines.

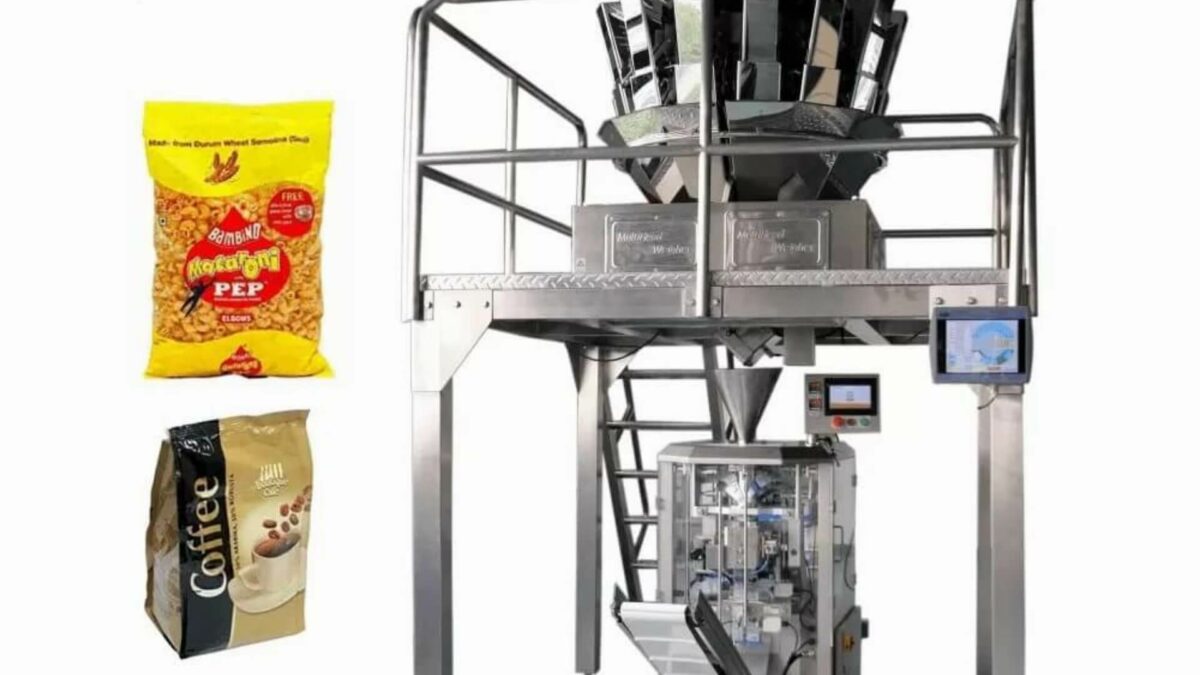

2. What is a vertical packaging machine?

Vertical packaging machines, on the other hand, are designed to handle powdered, granular, or liquid products. These items need to be packaged in a way that ensures their stability and prevents leakage.

A vertical machine can be used to pack the following items:

- Grainy coffee

- Sugar

- Milk powder

- Flour

- Powdered spices

- Rice

- Beans

Vertical packaging machines can also be equipped with robotic counters and feeding systems, as well as cartooning machines, with a variety of options. In vertical packaging machines, seal-making and bag-filling take place simultaneously.

The amount of time spent on any further preheating, heating, or cooling is determined by the time spent on a single cycle. This can end up creating a less refined look, which probably won’t win you over. Some of the advantages of vertical packaging machines are as follows:

1) Advantages of vertical packaging machine

Some advantages of vertical packaging machines are as follows:

#1. Heavy packaging efficiency

As the heavy load is transported to the evacuation belt, the vertical packaging machine has a bag support push rod. This makes the device more efficient.

#2. Easy to operate

Vertical packaging machines are easier to operate than horizontal packaging machines. Even first-time users can understand how the machine works with its easy-to-use control panel.

In addition, vertical packaging machines are usually equipped with automatic weighing and filling systems. This means you don’t have to waste time weighing and filling yourself. It will all be done for you by the machine.

#3. Equipped with various feeding systems

Liquid pumps, positive displacement fillers, and multi-head weighers are just some of the several feeding systems that can be added to a vertical packaging machine to meet the requirements of various packaging applications. This is one of the main benefits of using this type of machine.

It is able to fill products according to weight, volume, and individual units. Flow packaging machines, on the other hand, are often capable of packaging products that can be counted by parts.

#4. High speed

Vertical packaging allows for accurate bagging at rapid rates per minute, making it ideal for sticky or gelatinous items such as candy.

2) Vertical packaging machines have the following disadvantages:

Disadvantages of vertical packaging machine:

#1. The speed is not as good as the horizontal packaging machine

The maximum packaging speed of the vertical packaging machine is not as high as that of the horizontal packaging machine. A horizontal packaging machine can pack up to 400 bags. But no vertical packaging machine can pack so much. You should take this into consideration when deciding which type of machine to buy.

#2. Cannot pack solid goods

Solid items such as bread, biscuits, muffins, or even face masks cannot be packaged with vertical packaging machines. It is also important to consider the type of product you are packaging. If you plan to pack solid goods, then we recommend you choose a horizontal packing machine.

3. Important considerations when purchasing horizontal and vertical packaging machines

The product to be packed by the customer is the most critical factor to consider when choosing between horizontal and vertical packaging machines. Compared with horizontal packaging machines, vertical packaging machines can pack more kinds of items.

For certain items, horizontal packaging machines achieve maximum packaging speed because the products have consistent shapes, can be numbered, and can be filled by the piece. Taking hard candy packaging as an example, a horizontal packaging machine equipped with a sugar adder can reach more than 400 bags per minute, while a vertical packaging machine cannot reach such a speed.

Leave A Comment