Welcome to this article, which is an in-depth guide to carton strapping machine, Before you buy a carton strapping machine, check out our guide that covers everything you should consider to find the best machine for you.

1. What is a carton strapping machine?

A carton strapping machine is a kind of mechanical equipment used with the assembly line. And the types of carton strapping machines mainly include automatic strapping machines and semi-automatic strapping machines.

2. What is the structure of a carton strapping machine?

A carton strapping machine is a machine that uses banding tape to bundle a large number of cartons to complete the strapping operation. The carton strapping machine is composed of the main body, camshaft, electric heating head, swing rod, and electric heating head.

By removing the elastic horizontal pin and then removing the fixing screw on the tool roller holder, the length of the knife can be controlled by adjusting the screw, so that the length of the tool has adjustable and auto-adjustable performance. It has the characteristics of small size, reasonable design, compact structure, reliable work, firm assembly, high efficiency, and convenient maintenance. Ideal for binding carton-style staffs, Locke envelopes, books, and daily necessities. Bundling is to prevent items from being scattered and lost and to facilitate transportation and storage. carton strapping machine is widely used in related industries.

3. What is a common type of carton strapping machine?

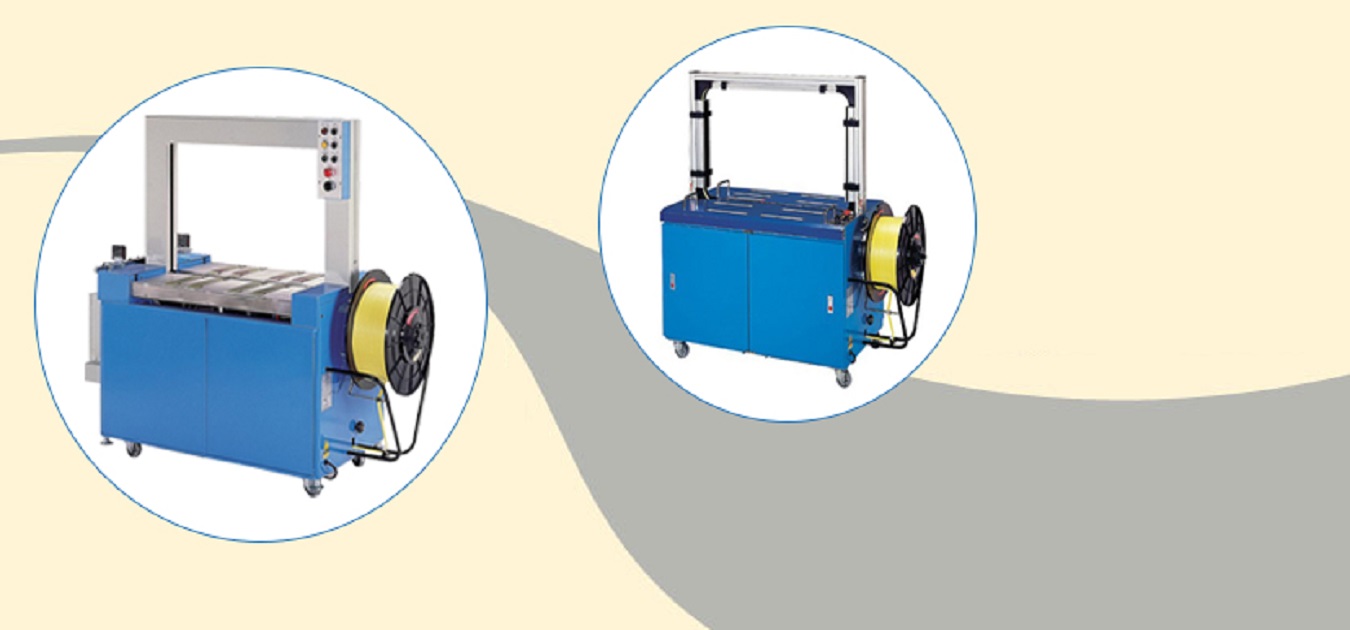

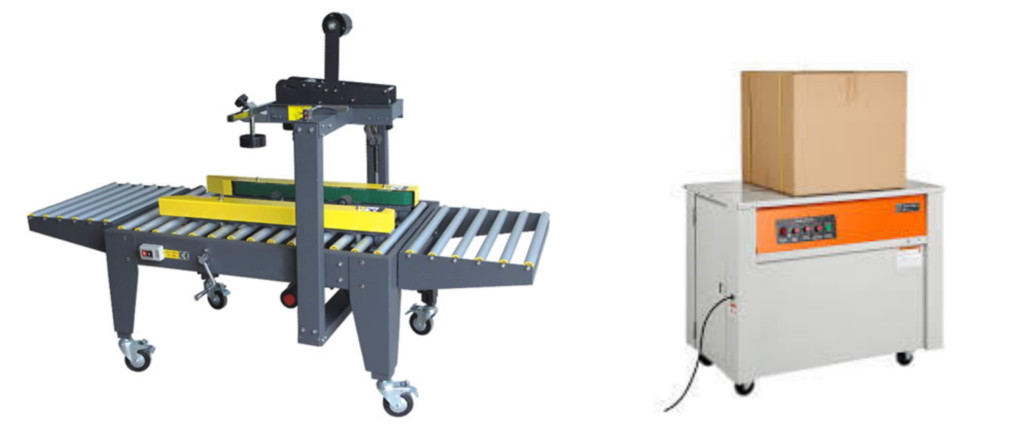

Sometimes a carton strapping machine is also called a strapping machine or binding machine, and there are two types of carton strapping machine; Semi-automatic or semi-automatic and automatic.

Semi-automatic strapping machines: Semi-automatic strapping machines rely in part on operator assistance and are typically suitable for low-volume strapping applications. Semi-automatic machines are ideal for strapping small quantities of boxes or pallets that conform to this bundling form but are too small to opt for a fully automated solution.

Automatic carton strapping machine: The strapping machine can be operated completely hands-free so that human interference can be excluded. With precise components, various sensors, and software, the machine can start working almost autonomously, sometimes it is enough to press the activation button. These automated systems can bundle dozens to hundreds of items in minutes. Therefore, they are also well suited for large quantities, such as industrial applications where thousands of items must be bundled every day.

Automatic carton strapping machines and semi-automatic carton strapping machines are available for carton strapping, and the type that suits you best depends on the exact application you want to use.

4. What are the characteristics of a carton strapping machine?

Here we list some common characteristics of a carton strapping machine:

1) Semi-automatic carton strapping machine:

- The operation of this machine mainly relies on human input.

- Ideal for changes in the size and shape of the item to be tied and the machine can be adjusted without additional time.

- These types of machines are very cost-effective in terms of advance and maintenance.

- Suitable for small to medium-sized applications.

- Small capacity storage.

- You don’t need moments of lightning-fast strapping right away.

2) Fully automatic carton strapping machine:

- Designed to work with minimal manual input.

- Ideal for strapping large numbers of items of similar size.

- Can be used as a stand-alone machine or integrated into fully automated production lines.

- Some models of automatic carton strapping machines can operate completely independently with minimal maintenance.

- If your business has a lot of strapping volumes, an automatic strapping machine is worth the investment.

5. What are the main advantages of carton strapping machines?

There are some advantages of carton strapping machines below:

- Lifting cover plate, easy maintenance.

- The new electric heating device has fast heating and long life.

- Single-chip microcomputer electronic control, complete functions, easy to operate.

- Automatic belt feeding is available as an option.

- Four packaging types ensure a variety of packaging requirements for customers.

- The cost of bagging is 30-50% lower than that of the existing market fully automatic baler.

- Energy-efficient, high-quality, and fast packaging methods can automatically carry out strap collection, heat sealing, cutting, and fully automatic shutdown operation.

6. What is the mechanism of the carton strapping machine?

The principle of a carton strapping machine is not complicated. Just like we usually bundle bags and cartons, carton strapping machines are done mechanically, like wrapping objects with rope and then tying knots to reinforce them. Just put the packaged items on the automatic strapping machine, the machine wire device starts to put the wire into the lead frame of the baler through the sensor on the panel, then shrinks the lead frame with the same wire, glues the strapping tape tightly to the packaging surface, heats it again through the side until that are melted together at both ends so that the whole packaging process is completed.

7. How to operate a carton strapping machine?

The operation process of the carton strapping machine is as follows:

- Turn on the power: Connect the power plug to the power supply, press the switch, and the indicator will light up.

- Preheat head: Adjust the temperature to desired and warm up for 1 minute. If the warm-up time is shortened, press and hold the quick heat button for about 5 seconds.

- Select the timing of belt feeding (belt length control), the time adjustment range is 0-6 seconds. Depending on the size of the package, you can adjust the desired transmission length.

- Start the motor: turn off the switch, and the motor will start, if it is not bundled within 30 seconds, the motor will automatically stop, press the feed belt or unwinding button to rotate again.

- Packaging positioning: Place the package on the machine table, grasp the lead to bypass the package, and insert the “tape entry”.

- Binding: After the carton enters the “tape entrance”, touch the microswitch, and the machine will automatically complete the actions of withdrawing, tightening, cutting, ironing, and restoring according to the carton. A tape of a certain length is then automatically sent, at which point the entire bundling process is complete.

- Belt feed and reset: If the feed belt is not enough, press the feed button.

- Unwinding and rewinding: Press the unwinding button to push the tape out of the machine, and the machine will automatically reset.

- Power off: After each use, turn off the power switch or motor switch.

8. What is the price of a carton strapping machine?

Cheap carton-strapping machines cost thousands of dollars, and expensive carton-strapping machines can cost hundreds of thousands. Usually, the price of a carton strapping machine is determined according to mechanical structure and performance changes.

9. What are the factors that may affect the price of carton strapping machines?

Here are the factors that may affect the price of carton strapping machines:

1) Brand factor

Just like different brands of notebooks, in terms of configuration, appearance, performance, etc., the price of notebooks is generally much higher than other brands of notebooks. Just as it is said to believe in the power of branding, everyone feels that buying branded things makes people more reassured.

2) Machine Quality

The quality of the product itself is a fundamental factor in determining the price. Including the value of various accessories, whether the life and use method of accessories are perfect, the technical content contained in the product, and other information, the quality determines the price of the strapping machine.

3) Market factors

Carton strapping machines on the market are more popular and in strong demand, which will affect the price of the strapping machines to a certain extent, and the impact of this factor will be reduced due to sufficient market supply. Similarly, during the annual sales season, the price of this machine will be higher, and this market-oriented price fluctuation will not have a substantial impact on the price. However, enterprises can also choose a reasonable time when purchasing machines to avoid these unnecessary passivities.

4) Marketing strategy

All items on the market have their own marketing strategies, some of which not everyone notices, but they are reflected in the price.

5) After-sales service system

With the continuous progress of society, people’s sense of service has been slowly cultivated. Now no matter what product you buy, if there is no good after-sales service system, then your product has lost half. Therefore, when choosing a carton wrapping machine, consumers would rather spend more money and buy a wrapping machine from those companies with good after-sales service. Because if the machine encounters problems in the future, then finding an after-sales solution is also a good guarantee.

10. How to maintain the carton strapping machine every day?

After the parts are repaired, the whole machine is assembled, and the machine is turned on to observe whether the machine is running normally. Heat the points appropriately, and put a small amount of carton-wrapped mechanical special oil to melt and cover the surface of the cylinder, and then cut off all the power supply. If necessary, you can spray paint on the surface of the machine, cover it with plastic paper after drying, and store it in a dry place.

- If the chain is too loose, it can be adjusted by removing a few segments first, and if it has been severely stretched, it should be replaced. When using carton packaging machinery, it should be used in accordance with a certain amount and principle, and maintained in a certain way, timely solve different fault problems, adjust and replace the chain should pay attention: to the installation direction of the spring card at the chain joint should be consistent with the running direction of the chain, so as to avoid impact, jump, and even collision and falling off during operation.

- All rolling bearings are dismounted, cleaned, and filled with new grease, which can be calcium-based.

- Remove dirt from all friction surfaces, especially chains and sprockets to be cleaned and relubricated.

- The maintenance and repair of carton strapping machines require certain technicians to maintain and repair to ensure the quality and performance of carton machinery in use, which plays an important role and value in carton production.

- Check whether the stove leaks smoke, if smoke leakage is found, the drum smoke ring, stove, and chimney should be checked, and the damage should be repaired and replaced in time. The electric heating model should be checked for damage to the electric heating tube, and if it is damaged, it should be replaced.

11. What are the main precautions for carton strapping machines?

Please confirm the power supply of the machine and do not plug in the wrong power supply. This machine adopts a three-phase four-wire system. The flower wire is a grounding neutral wire for leakage protection.

- Do not pass the head and hands through the track of the belt during operation;

- Do not touch the heating plate directly with your hands;

- Do not wash the machine with water. When the workplace is wet, the operator should not work in the place barefoot.

- When the machine is not in use, please reel the belt in the storage belt magazine back to the belt tray to avoid deformation when used next time;

- Do not stick oil on the surface of the conveyor rollers;

- The machine is not used to unplug the power supply;

- Do not change the parts on the machine at will;

- The main components should be lubricated frequently with oil.

12. What is the after-sales service of the carton strapping machine?

Generally, we guarantee after-sales service to customers in the form of technical support, returns,s and compensation.

1) Technical support includes:

There is some service below:

-

Phone support

Technicians provide customers with technical guidance services such as project consultation and fault diagnosis in the form of service hotlines, whether they are located in the city or remotely, they can achieve immediate response and achieve customer satisfaction.

-

On-site support

When telephone support does not solve the problem, or direct on-site service is required according to customer requirements, the company will assign experienced professional technicians to provide on-site service.

2) Return to the factory for repair

When the problem cannot be solved by phone or on-site support, the customer has no special request and returns to the company’s nearest repair point for repair.

3) Compensation

If the machine is damaged in transit and the customer does not want to wait for another new machine, we will provide you with the same amount as the machine. This only applies if the machine is damaged during transport due to an accident that cannot be prevented.

Leave A Comment