With research showing that 38% of online retailers are concerned about meeting customer expectations for fast delivery, how do you, as a small business, deal with this? Our Packaging 101 series has covered a number of topics to develop your packaging knowledge over the past 11 months.

This month, we want to explore something that might seem scary to most businesses…packaging automation! Even small businesses can benefit from automation when stereotypes are broken down.

1. What is Packaging Automation?

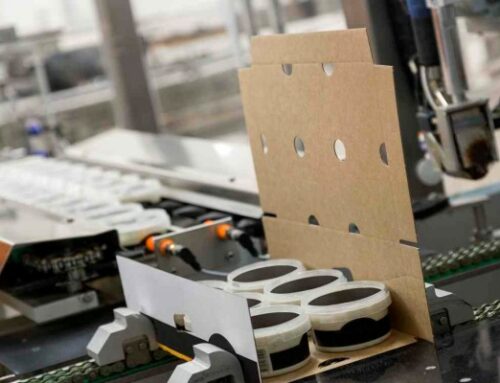

Packaging automation is when you use packaging machinery, large or small, to help you with the packaging process. This often means reducing manual touchpoints in the packaging line. For example, this could include automatically cutting tape when it reaches the desired length; automatically placing products into mailing bags ready to ship.

Using an automated packaging system essentially allows you to reallocate valuable resources to high-value tasks or in ways that better suit your operations. You can enhance most aspects of your packaging process, from picking and packing to shipping and packing. There are wrappers for it all.

Packaging automation can be an investment, depending on the solution you are looking for. Purchasing an automated packaging system can have significant upfront costs, but the savings you make in other areas of your operation will more than offset this cost in the long run.

Plus, there are some really cost-effective automation options. A good example is water-activated masking tape dispensers – they cost around £1,500 or less. You can also opt for less expensive semi-automatic machines, and they could be a great first step toward automation if you want to give it a go!

2. What are the benefits of an automated packaging system?

Your operation can benefit from packaging automation in the following ways. Depending on the machinery you choose, there can be knock-on benefits such as saving on shipping costs and reducing damage!

Benefits of packaging automation:

- Reduce waste and material costs – Packaging automation reduces overuse and waste by using materials more efficiently.

- Increased productivity and reduced packaging time – it speeds up every part of the process and reduces the number of physical touchpoints, so packers’ skills can be used in other areas. It can also help reduce the need for seasonal temps!

- Save storage space and material – Using automation means you use the right amount of packaging material you need, so it frees up storage space for other uses and controls overall material usage.

3. 4 signs your small business is ready for automation

- You are having difficulty fulfilling orders and customer complaints are on the rise.

- Your business is generating more and more packaging waste.

- You constantly need to hire new staff for your production and/or packaging lines.

- You see an increase in customer complaints about damaged goods (package quality may be less reliable if demand is too high).

If your operation is experiencing one or more of these issues, then employing some form of packaging machinery may be a good solution for your business. Let’s explore some of your options…

4. Great automation solutions for small businesses

Where does packaging automation start? We’ve narrowed down some great options that are perfect for small businesses looking to grow their business. We’ve broken it down into process-specific systems so you can decide what works best for your business.

1) Tape

You have many tape automation options, some of which include:

- Manual Water-Activated Tape Dispenser – As the most affordable option for this one, it’s not fully automated (as the name suggests). You have to manually adjust the length, so unlike other options, this isn’t done for you. For businesses with low shipping volumes, it wets and cuts the tape, which is a great first step toward automation.

- Automatic Water-Activated Tape Dispenser – This tabletop dispenser dispenses preset lengths of tape to speed up tape application. It also means you get the correct amount every time, minimizing waste.

2) Fill in the blank

The automated void filling can help you reduce packaging time, meet demand and help you effectively protect your products. Depending on the material you choose, how cost-effective it is, and whether it’s environmentally friendly; you can get many different types of void fillers and machines that have different benefits for every business. These are just some examples available.

- Manual Paper Gap Fill Dispenser – The Ranpak FillPak TT machine is the entry-level option for gap-fill automation. Simple installation, small footprint, won’t take up too much space! It is easily operated using a foot pedal, so the void filler can be dispensed directly into the box, reducing packing time.

- Automatic Paper Void Fill Dispensers – These dispensers are controlled by your foot pedal to automatically fill packages. They can also be programmed to assign the appropriate length of material to each of your packaging options, reducing the total amount of material you use.

3) Stretch wrapping paper

It may not be something your business needs right now, but in the future, it might be helpful to know that you can automate your stretch wrapping process.

- If you manually pack 10-15 pallets (or more) per day, it’s time to consider a pallet packer. It can significantly reduce the amount of stretch wrap you use and reduce manual handling

5. How can you expand packaging automation as your business grows?

As your business grows, it can feel overwhelming to take control of your business, no matter its size. Adding (even a small element) to an automated packaging system is a great way to get your business started. Over time, as it develops, you can explore larger and fully automated options.

Leave A Comment