You may not have noticed that corrugated boxes are just about everywhere. More than 95 percent of goods consumed in the United States are packaged and shipped in corrugated boxes. This is because corrugated boxes are universal. Therefore, they are considered a staple product in the retail industry.

But you may still be wondering what is corrugated packaging. Why is it commonly used and when is it used? Read on to answer these questions.

1. Understanding corrugated packaging

Corrugated packaging is a durable, versatile, and cost-effective packaging material consisting of 3 or more sheets of corrugated cardboard (also known as boxboard). Corrugated boxes are made from flat parts called liner boards. The medium is the paper that is grooved and glued between the liner boards.

2. History of corrugated packaging

Corrugated packaging as we know it dates back more than a century and was created to pack and store goods for longer periods of time. Corrugated paper was invented by two Englishmen, Healey and Allen, in 1856. Using two grooved rollers, the corrugated paper is fed into a hand-operated machine to make a grooved paper lining that can be used in hats.

However, the corrugated paper used for hats is one thing, and the corrugated paper packaging used to ship merchandise is quite another. Responsible for the combination of the two functions was the American Albert S. Jones. He was the first person known to man to use corrugated paper to pack fragile items. This includes bottles and other fragile items, in the same way corrugated packaging is currently used.

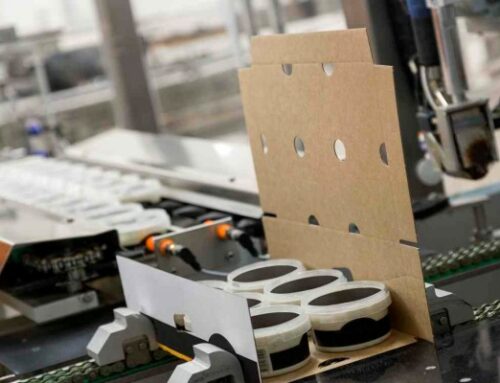

3. How is corrugated packaging produced?

The method of making corrugated packaging hasn’t changed much since the 1850’s. But how is it made?

Two sheets of plain paper and a liner are glued to the corrugated inner material called corrugated paper in corrugated packaging. These unique layers are stronger when used together than individually. If you look closely at corrugated packaging, you will notice a weave pattern. This is what gives corrugated packaging its structure and stability.

4. Why use corrugated packaging boxes?

Here is a list of reasons why you should consider corrugated boxes as your packaging option:

1) Stronger than cardboard

Corrugated boxes are stronger than cardboard, so you can rest assured that whatever you put inside will be safe. Additionally, this packaging is crush and crush resistant. Therefore, corrugated packaging is safe, secure and protects your items.

2) Various sizes

Corrugated packaging comes in different sizes. While it’s durable, it’s lightweight, making it perfect for just about anything that needs protection without adding bulk.

3) Can be decomposed and reused

Boxes made of corrugated cardboard can be easily broken down and stored. Additionally, it can be shipped without compromising the structural integrity of the package.

4) Fit around

Packaging components are made from recycled and renewable materials, including kraft paper material, making it an eco-friendly packaging option consumers are sure to love.

5. The difference between corrugated packaging and cardboard packaging

Online purchases have experienced an incredible surge due to the Covid-19 pandemic. So, of course, customers expect their packages to arrive safely and with their contents intact. Unfortunately, boxes that arrive ripped, damaged, or crushed leave a bad impression on consumers and create a poor experience when unboxing. This is why it is important to consider the shipping box that should be included in the package.

Cardboard and corrugated packaging are the most popular product shipping boxes. However, it’s crucial to know the significant differences between the two so you can weigh your decision on which type of packaging you should get.

1) Cardboard packaging

Cardboard or carton packaging is made of thick paper or pulp. It is then fabricated into small packages or materials to help strengthen the structure of the smaller material so that the contents do not deform.

This type of packaging is inexpensive and easy to use as part of most shipping strategies. Still, it may require additional packing materials to keep items from being crushed or damaged, such as foam inserts and bubble wrap.

2) Corrugated packaging

Corrugated packaging consists of multiple layers of material that are stronger when put together. The inner and outer linings are filled with grooved material in the middle, making the whole part stronger and stronger.

Corrugated boxes are the perfect balance of strength and weight for weight, so they are perfect if you need to ship a variety of products with care. In addition, they are resistant to humidity and sudden temperature changes.

Obviously, no container is completely immune to crushing or prolonged exposure to rain, sleet, or heat. Still, corrugated packaging is a great option if you want extra confidence that your product will arrive safely.

6. When should corrugated boxes be used?

Corrugated boxes are ideal for items that need to be transported from warehouses to processing centers and onto delivery vehicles. With multiple people and machines handling packages, your boxes must withstand being thrown, dragged, slipped and even dropped. Another benefit of corrugated packaging is that you can fully customize your packaging.

Leave A Comment