Welcome to this guide. this article is a Corrugated Cardboard Guide for E-Commerce Shipping. Read on to learn more.

1. What is the best corrugation grade and corrugation for my DTC shipping box?

We receive many phone and web inquiries regarding eCommerce shipping boxes:

- Is the E-flute too thin for the shipping box?

- What is the difference between 32ECT and 200#?

- What is Mullen? Can I use a C-shaped flute for extra power?

- Will my board choice affect print quality?

Comparing all possible board and ink options is exhausting. All possible combinations are overwhelming. The more time you spend reading on the web, the worse it gets because most of what you find isn’t real-world or application specific. The correct answer is the one that is very specific to what works best for your project, not to a theoretical application that has nothing to do with your needs.

2. Relax, there aren’t as many viable corrugated cardboard options as you might think.

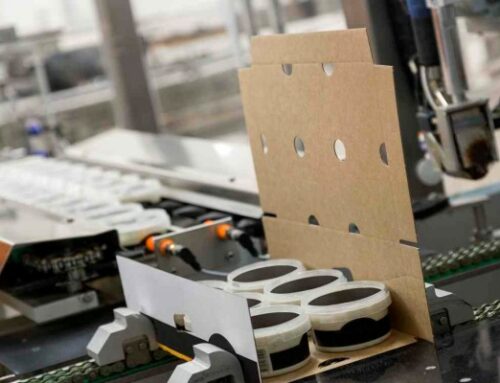

Many times, it’s not a question of what you want, but what is available and best suits your specific needs. One of the biggest concerns is the thickness of the board, which is mostly determined by the grooves. This is the thickness of the middle corrugated layer sandwiched between the outer and inner liners as shown in the attached image

You can see about a dozen different types of corrugated cardboard, but over 85% of the millions of shipping boxes we produce each year are made with E-flute. Less than 10% of the cases we manufacture are made from B flutes. That’s it, except for occasional C-channel or double wall applications for e-commerce applications. That’s really all you need to know about board options for the vast majority of DTC box applications.

3. Understanding Mullen with ECT

The method explained to me over forty years ago is that the original method of testing corrugation strength was the Mullen or Bursting Strength Test. Essentially, it measures how much pressure (in/out or out/in) a corrugated box can withstand before the cardboard punctures or bursts. Stacking became more important when boxes started moving more by truck than by rail, which is when the ECT (Edge Crush Test) was developed. This is a whole new way of looking at boards, focusing on up/down (stacking) strength rather than puncture resistance.

Industry-wide, the most used board level is 32ECT, which can satisfy most applications. Our favorite grade of paperboard is the 200# test, not because of puncture resistance, but because it has better/thicker paper for the inner and/or outer lining. Guess what? This also gives us a better surface to print on, which is important considering the high quality graphics our clients expect from us. By the way, in rare cases we can even upgrade mid-tier, mid-tier boards, but keep in mind that unusual board combinations may have higher minimums.

4. Corrugated cardboard questions are welcome!

As always, our brand packaging consultants are happy to answer any questions you may have about structural design, corrugated board construction, your application and requested printing requirements. This post is kind of a snapshot or an overview, but we can provide the technology and depth you need.

Leave A Comment