Welcome to this article, which is an in-depth guide to carton packing machines, If you’re looking for any information about carton packing machines, you will find it right here. So keep reading to learn more.

1. What is a carton packing machine?

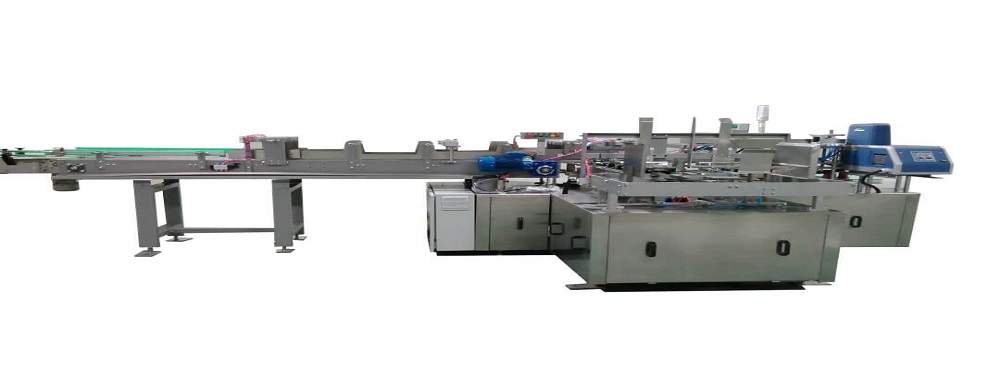

A carton packing machine is a machine for mechanized measures to pack cartons. A carton packing machine, also known as a carton packaging machine, is the use of a machine to automatically wrap cardboard containing glass bottles, PET bottles, cans, large bottles, etc, suitable for beer, beverages, condiments, and food. And other machines all use professional display control. The carton packing machine is greatly convenient to operate and is indispensable equipment for automated large-scale production, which can greatly improve product packaging efficiency.

2. What is the mechanism of a carton-packing machine?

There is some mechanism of carton packing below:

- Container inlet: On the inlet conveyor belt platform, the garden-column type container is divided into multiple lines by the divider plate and the pneumatic vibration rail, while the single-lane entry and special shape of the container are divided into multiple lines by the separation gate.

- Container divider: The container divider is driven by two motor drives to gently and evenly separate the containers. To handle containers that are not stable enough, such as five-jaw PET bottles, transition channels can be used between conveyor chains. After the containers are grouped, they are pushed out by the pusher.

- Cardboard inlet: The cardboard is neatly stacked on a roller conveyor belt and then automatically guided into the lifting cardboard storage located below the container inlet. The vacuum jaw extracts the top piece of cardboard from the lifting memory and places it horizontally on the cardboard inlet.

- Package forming device: The cardboard is transported under the container group and the ends are mechanically folded. The side cover is folded in with a rotating copper, coated with hot melt by the nozzle, and glued to the bottom cover.

- The circulating sealing chain presses against the bottom cover and carries the package through the wrapping machine.

- The top cover is then folded off and glued to the sealing edge.

- Finally, the sealing chain closes the top cover from above. Since the package runs longitudinally and the bottom is already firmly glued, the top cover can be glued very accurately.

3. What are the components of a carton packing machine?

There are some components below:

1) Fuselage

The fuselage is the rigid skeleton of the packaging machine, which mainly plays the role of supporting and positioning each component. All mechanisms or devices are installed on top of it. The fuselage must be stable and the center of gravity as low as possible to facilitate smooth mechanical operation. The material, structure, shape, decoration, etc. of the fuselage are designed according to the use and characteristics of the packaging machinery.

2) Control system

The function of the control system is to control the relevant parts of the packaging machine and coordinate their process functions. Complete the packaging on time and in order. The devices of the control system mainly include photoelectric control, electronic control, electro-mechanical control, pneumatic control, jet control, etc. The most common system of these is electro-mechanical control.

3) Power part

The power part is the power source of packaging machinery, which can be a motor drive, hydraulic drive, air pressure drive, etc., and is mostly used to drive by an electric dynamo.

4) Transmission mechanism

The transmission mechanism varies from different models and transmits power and movement to various actuators, control elements, auxiliary mechanisms, etc. Its main transmission components are gears, ratchets, cams, sprockets, belts, worm gears, screw nuts, etc.

7) Actuator

The actuator is the core part of the packaging process operation and auxiliary operation and often uses movable mechanical components or manipulators to realize packaging operations. The packaging process operation mainly includes molding, filling, wrapping, sealing, labeling, etc.; Packaging assistance operations include the supply and transfer of packaging materials, packaging containers and products, and the output of finished products.

4. What are the applications of a carton packing machine?

In the early stage of industrialization, the carton has always been packed by manual means, and with the development of large-scale mechanization, the corresponding more subdivided machine came into being, carton packaging machine is also formed in this process, replacing manual labor, the paper packaging machine is widely used in beer, chemical, food, medicine, and other industries, supporting in the filling line, etc., secondary carton packaging for all kinds of bottles and cans, greatly improving production efficiency.

5. What are the advantages of a carton packing machine?

Compared with other types of packing machines, the carton packing machine we provide has the advantages below:

- The modular construction of the machine provides a high degree of flexibility;

- The linear arrangement of the machine makes the packaging of cartons particularly accurate;

- Use the internationally renowned servo control system;

- The control cabinet is pre-wired to make the start fast;

- Short format change time;

- It does not need to be maintained very frequently, and it is very durable;

Other information that you might need to know:

In order to create the greatest benefit for yourself within the specified time, it is necessary to ensure that your packaging production line runs well and there will be no errors in the production process, so as to avoid the impact of errors and failures as much as possible, and only then will the company obtain the greatest benefits.

The level of automation is constantly increasing in the manufacturing industry, and the range of applications is expanding. Automation in the packaging machinery industry is changing the way the packaging process works and the processing of packaging containers and materials. The packaging system that realizes automatic control can greatly improve production efficiency and product quality, significantly eliminate errors caused by packaging processes and printing and labeling, effectively reduce the labor intensity of employees, and reduce the consumption of energy and resources. Revolutionary automation is changing the manufacturing methods of the packaging machinery industry and the way its products are transmitted.

The design and installation of automatic control packaging systems have shown a very obvious role in improving product quality and production efficiency in the packaging machinery industry, or eliminating processing errors and reducing labor intensity. Especially for the food, beverage, pharmaceutical, electronics, and other industries, it is crucial. Technologies in robotics and systems engineering are being further deepened and more widely used.

6. What are the characteristics of a carton packing machine?

There are some characteristics below:

1) Packaging form

automatic transmission, unpacking, boxing, batch number printing, sealing, waste removal, and other characteristics, compact and reasonable structure.

2) Easy to operate

servo/stepper motor, touch screen, PLC programmable control system, man-machine interface display operation is clearer and simpler, high degree of automation, more humanized;

3) Wear protection

the frame and plate have sufficient strength and rigidity, the frame is equipped with the main drive motor and clutch brake of the machine, the machine plate is equipped with various transmission systems, and the torque overload protector can realize the main drive motor and transmission parts in the case of overload to protect the machine parts from damage.

4) The height is configurable

The machine can adjust to different heights to accommodate different sizes of packages so there is no need to change machine molds. It means that one machine can be used for many purposes that show incredible flexibility and versatility of the machine. Generally, it is suitable for all types of corrugated cardboard or lithographic laminated boxes, allowing the operation of a wide range of box types.

5) High safety

if there is no product – the box will not fall, and the machine will automatically stop and sound an alarm.

- The automatic photoelectric detection and tracking system is adopted to save packaging materials, and the box body will not fall due to empty materials

- The vacuum suction cup used by this machine is a ZL112 vacuum generator (SMC), automatic vacuum box taking, wide angle unpacking, to ensure the unpacking accuracy

- It can be produced with an aluminum-plastic packaging machine, pillow packaging machine, 3D packaging machine, filling line, filling machine, labeling machine, ink-jet printer, online weighing machine, other production lines, and other equipment.

- According to customer needs, design an automatic feeding machine, and box entry system.

- According to customer needs, you can choose hot melt adhesive machine sealing, such as hot melt adhesive spraying machine, or mechanical brushing.

7. How to operate a carton packing machine?

Here we provide you with four major operation steps of packaging machines and their precautions:

1) Firstly, place the packaging machine material in the right position.

We need to prepare the materials of the packaging machine, such as your products, your packaging containers, the materials of the products, etc., and put them in the corresponding positions for the normal use of the packaging machine.

Notes:

It should be noted here that before using the packaging machine, it is necessary to ensure the cleanliness and hygiene of the packaging machine, especially the packaging machine with filling technology, which is easy to hide dirt, thus causing secondary pollution of the product. In addition, the packaging container should fit the specifications and dimensions of the packaging machine.

2) Secondly, turn on the power switch of the packing machine.

After we have prepared the materials and containers used in the packaging machine, then turn on the power switch of the packaging machine, and the packaging machine is officially started.

Notes:

It should be noted here that before opening the power switch of the packaging machine, it is necessary to check its power line, if the power line has exposed places, it is necessary to replace the power cord in time, otherwise, it is easy to cause the risk of leakage, and at the same time, it is also very easy to damage the packaging machine equipment.

3) Thirdly, packaging machine parameter setting is another important step.

After the power of the packaging machine is turned on, the touch screen of the packing machine will also start, we have to click to enter the parameter setting of the packing machine, according to the instruction manual of the packaging machine to set the temperature, sealing time, sealing speed, filling capacity value and other parameters to ensure the normal use of the packaging machine.

Notes:

It should be noted here that the parameters of the packing machine must be set according to the instructions of the packaging machine, for example, the sealing temperature of the packaging machine is 200 degrees, if the temperature is set below 200 degrees or higher than 200 degrees, there will be bubbles in the seal or the phenomenon of the improper sealing film.

4) Finally, the packing machine starts to operate.

When everything is ready, the packaging machine can be officially started, directly press “start” on the main menu, and the packaging machine can run normally!

Notes:

During the start of the packaging machine, we must observe the temperature of the machine at any time, if the temperature is overheated, we should stop the operation, and wait for the packaging machine to cool down for half an hour before the operation, so as not to cause the packaging machine equipment failure due to excessive temperature. In addition, if the packaging machine has abnormal noise during operation, the packaging machine should be turned off immediately and started after inspection and maintenance.

8. How to choose a carton packing machine?

First of all, you need to determine which products you will pack in the packaging machine you will buy. Packaging machinery manufacturers generally have a variety of products, but some clients in the purchase of packaging equipment, hope to be able to package their own all types of products through a device. In fact, this is a very wrong idea, because generally speaking, the special machine than the compatible machine packaging effect is better. The variety that can be packaged by packaging equipment should not exceed 5 varieties, and the products with too large size differences should be packaged separately.

As far as possible, choose a machine with simple operation and maintenance, complete accessories, and automatic continuous feeding, which can improve packaging efficiency and reduce labor costs, which is suitable for the long-term development of enterprises.

Choose a long-established packaging machine enterprise as much as possible, and the quality is guaranteed. Choosing a machine produced by a mature technology and stable quality enterprise can basically achieve the effect of a faster and more stable machine, low energy consumption, low manual work, and low scrap rate. In the process of use, if you buy a low-quality machine, the packaging film that accumulates and wastes in the future daily production is not a small amount, especially now that the packaging materials are rising.

In terms of after-sales service, the “circle” should have a good reputation. After-sales service is timely and on call, especially important for food processing enterprises for which the freshness of the products is of great importance.

If there is a field investigation, we should pay attention to the big aspects, but also pay attention to the small details, often details decide the quality of the whole machine. Bring samples for testing whenever possible

9. What’s the normal price of the carton packing machine?

The price of a common carton packing machine usually is hundreds of dollars. But there are very expensive carton-packing machines available. Their machines may have some advanced features or the production procedure is very complex.

10. What are the factors that determine the price of a carton packing machine?

There are some factors below:

1) Brand factors

Just like different brands of notebooks, in the case of configuration, appearance, performance, etc., the price of notebooks is generally much higher than that of other brands of notebooks. Just as it is said to believe in the power of the brand, everyone feels that buying branded things makes people more assured.

2) Machine Quality

The quality of the product itself is the basic factor that determines the price. Including the value of various accessories, whether the life and use method of accessories are perfect, the technical content contained in the product, and other information, the quality determines the price of the sealing machine.

3) Market factors

The automatic sealing machine on the market is more popular and has strong demand, which will affect the price of the sealing machine to a certain extent, and the impact of this factor will be reduced due to the sufficient supply in the market. Similarly, in the annual sales season, the price of this machine will be higher, and this market-oriented price fluctuation will not have a substantial impact on the price. However, enterprises can also choose a reasonable time when purchasing machines to avoid these unnecessary passivities.

4) Marketing strategy

All the goods on the market have their own marketing strategies, some of which are not noticed by everyone, but they are reflected in the price.

5) After-sales service system

With the continuous progress of society, people’s sense of service has been slowly cultivated. Now no matter what product you buy, if there is no good after-sales service system, then your product has already lost half. Therefore, when consumers choose a sealing machine, they would rather spend more money and buy a sealing machine from those companies with good after-sales service. Because if the machine encounters problems in the future, then it is also a good guarantee to find after-sales solutions.

11. What are the common problems that may arise on a carton packing machine?

There is sometimes occurred that the electromagnet of the machine does not absorb. The cause of this failure is mostly the internal fault of the host, the solenoid coil being blown out, the line interruption, and other reasons.

The solution is: first check whether the host is internal or external problems;

Secondly, check the electromagnet fuse, check whether the electromagnet has signs of power, eliminate mechanical jamming, and detect the internal power supply when everything is normal; Often encountered in the weighing packaging machine is the cause of this failure: sensor damage, bridge voltage failure, line connection or interruption is wrong, the elimination method is: detect the load signal of the sensor and the connection or host, close to detect the bridge and amplification circuit or computer output display circuit, sometimes there will be poor system stability resulting in unstable bag volume to solve this problem can test whether the line is in good condition.

However, the weary of parts in use and poor lubrication will cause damage to parts and may expand the occurrence of faults and accidents, so it is very important to quickly find and eliminate faults. Don’t turn to the manufacturing plant for a glitch and win valuable time and money.

Here are a few places and repair methods that are prone to failure:

- Fault: Cut the steel strip

- Causes:

1) Cutter wear or failure

- Maintenance method: check whether the cutter or cutter holder is worn or faulty, if the wear is serious, it should be replaced

2) Air pressure decreases

- Maintenance method: check whether the working pressure is normal;

The cutting steel belt force comes from the blockade cylinder see fault phenomenon;

Check the blocking operation:

- Fault: The locking clamp is not subjected to enough pulling force

- Cause: Clamp block connection holes or connection pins are worn

- Repair method: Check these parts when the groove depth is shallow and replace them if necessary.

12. How to maintain a carton packing machine?

A machine only operates better if you take good care of it. Asides from the daily operations, you also need to pay attention to taking good care of it. The maintenance methods we would like to provide you with include:

- Remove the chips or dirt in the machine once a week.

- Once a month, clean and lubricate the upper skateboard, the middle knife, and the front top knife mentioned in the previous section.

- After doing the above two maintenance once every three months, add some lubricating oil to all (shaft, core) and bearings.

- Replenish the oil in the wheel box of the reducer once every two years.

- It must be noted that several parts cannot be refueled: a send-back with rollers.

- Every time you refuel, do not add too much, so as not to cause the failure of the microswitch due to immersion in oil.

Leave A Comment