Cartons are something we often need to use, especially now that the demand for online shopping is increasing, and a large number of cartons are needed to transport express delivery, so many express companies need to customize a large number of express boxes, so now there are more and more carton manufacturers, So are you curious about the operation steps of the carton manufacturer after receiving the order? Next, the editor will introduce them one by one to everyone, hoping to help everyone.

1. What is carton manufacturing?

Carton manufacturing is a manufacturing process of cardboard production plus carton processing. Generally, the corrugated cardboard enters the hot plate part after passing through the laminating machine to complete starch gelatinization and bond with the cardboard.

2. What equipment is needed for carton manufacturing?

The required equipment is a paper separator, a printing slotting machine, and a binding machine. Funding depends on the equipment you buy, new or old. Generally speaking, equipment needs about one million funds to purchase.

There are large and small carton factories. Take, for example, the large cardboard boxes that hold factory equipment. A corrugated cardboard production line of large carton equipment costs tens of millions, plus some miscellaneous things, it is only tens of millions. Any medium-sized carton factory needs about 4 sets of production equipment. Some senior operating technicians are needed, and some small carton factories can produce cartons with a single nailing machine, so it is not easy to open a carton factory.

If you make ordinary cartons, you need some advanced equipment. A printing press for corrugated cardboard production and a box sewing machine will suffice.

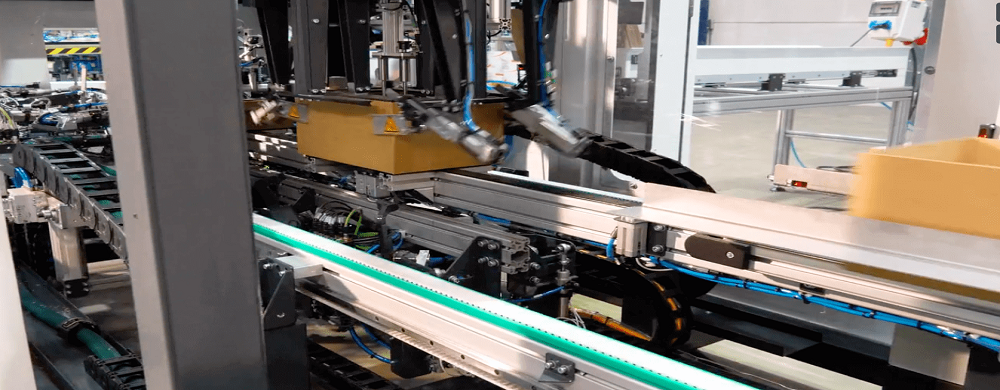

The carton packaging equipment is a carton forming machine, and the unpacking machine refers to the automatic completion of unpacking, forming, and bending of the bottom hinge. Now paste the tape on the lower part, open the box board folded into cardboard, fold the bottom of the box according to a certain procedure, seal the tape, and transport it to the special equipment for packing. Automatic carton forming machines and automatic unpacking machines are assembly line equipment for the automatic unpacking of large quantities of cartons, automatic folding of the lower cover, and automatic back-sealing tape. installation.

3. What is the process of carton manufacturing?

The following is the process of carton manufacturing:

1) Order

Cartons are also customized products. After receiving the order, determine what kind of paper the customer needs. The surface paper is divided into a white paper and kraft paper, and the bottom paper is generally kraft paper. The weight is chosen by the customer. There are several layers of corrugated paper in the middle, including A, B, E, and corrugated paper. See which one or several kinds are produced in your factory.

2) Cardboard production

The order taker calculates the size, places the order, and goes to the workshop to produce the cardboard. Some carton factories belong to first-class factories, and they arrange everything from base paper production to cardboard by themselves. Some carton mills buy cardboard from outside manufacturers. They don’t need to produce the cardboard themselves, they only need to order the corresponding size of cardboard from other manufacturers. The produced cardboard bobblehead parts are all pressed. At that point, you can simply print directly.

3) Printed cardboard

Cartons generally have watermarks, and the color is relatively single. Generally, there are one or two colors in the middle. Color printing is generally more than four colors. Before cardboard printing, the machine needs to be adjusted according to the size, and one or two sheets should be printed to check the printing content and color size. In the production process, the cardboard printing machine can slot at the same time.

4) Packaging and storage

The final step is packing. When packing, five boxes or ten boxes are usually used as a group, and the boxes are packed by a box packing machine. According to the order quantity, put the carton into the warehouse, and wait for the customer to pay for the delivery.

4. What are the processes of carton manufacturing?

There are several processes for printing, printing plates, and watermarks:

1) printing

A resin plate or rubber plate is used for the watermark carton. Printing accuracy is not high. It fits better than a normal outer box. Common single-color or two-color printing, without any treatment on the surface. Printing paper is generally kraft paper with a rough surface. At present, our watermarking technology is relatively advanced.

Color-printed cartons generally refer to offset-printed cartons, which use indirect printing, that is, to print carton paper first, and then mount the printed paper on corrugated cardboard. Due to the relatively high resolution of the PS plate, very fine printing patterns can be printed, which can be used for surface treatment, such as lamination, glazing, etc., and the printing effect is exquisite.

2) printing plate

It is possible to make the basic image-bearing surface of the printing process from various materials, such as metals (such as those used in letterpress and plate printing) or rubber., or plastics (such as those used in flexographic printing).

3) Watermark

The printing machine uses the rubber roller (ink roller) to transfer the ink in the ink tank to the printing plate on the printing plate cylinder, so as to print the required text or pattern and other information on the surface of the carton.

printing art:

Loading, paper feeding, printing, (grooving, die-cutting) chip removal→sealing (tape, nail box, gluing), unit bundling, stacking→warehousing, transportation.

According to the design specifications of the carton, the unnecessary part of the printed cardboard is cut off; the corrugated cardboard is partially destroyed by the edge pressing device, which is convenient for packing.

5. What are the accessories for carton making?

The accessories made of cartons are as follows:

1) Stapler

Stitching is a method of connecting cartons to boxes. At present, the nail box machine has three modes: manual, semi-automatic, and fully automatic. When nailing boxes by hand, the distance between the head and the tail and the uniformity of the nail pitch are all controlled by the operator’s proficiency, which is labor-intensive and the production efficiency is not high. Semi-automatic and fully automatic nail box machines reduce the physical strength of workers on the one hand, and on the other hand improve the uniformity of the nail distance and improve the quality of the product.

2) Folder gluer

Gluing boxes is another method of joining cartons into boxes. For some industries, the cartons used can only be bonded with adhesives, such as the food and beverage industry. At present, generally speaking, in carton production enterprises, manual gluing still accounts for a considerable proportion. In addition to manual folder gluing, semi-automatic and fully automatic folder gluing machines can greatly improve production efficiency and ensure product quality (the scissors for gluing box production are poor). At present, the company is equipped with automatic folding and gluing machines for printing, slotting, die-cutting, and gluing.

6. What problems should be paid attention to in carton manufacturing?

The following are 8 issues that need to be paid attention to in carton manufacturing:

1) Determine the custom size of the carton (ie the length, width and height of the carton)

Generally, the thickness of the custom-made three-layer carton is about 3.5mm, and the thickness of the custom-made five-layer carton is about 7mm, so be sure to measure the length, width and height of your object first. Then add the thickness of the carton (up to 0.5mm for the height of the carton). This is the size of the carton’s outer box. Generally, custom-made carton manufacturers default to the outer box size.

Outer box size design: Generally, the width data is small, and the material is the most economical. Therefore, according to the situation of your own goods, you must tell the custom-made carton manufacturer whether the size you are talking about is the size of the outer box or the size of the inner box.

2) Carton material customization

According to the weight of your own goods and your own cost, reasonably choose the material of the custom-made carton. Cartons are made of cardboard, so you need to understand the concept of cardboard. Our common custom cartons are made of corrugated cardboard. Yes, corrugated cardboard is divided into surface paper, corrugated paper, core paper, and inner paper; the quality of the material is generally related to the weight per square meter. The heavier the weight per square meter, the thicker the mass. Paper weight is 120g/140g/170g/200g/250g. Generally, the material of custom-made cartons is smooth from the outside, and the softness and hardness of the hand feel are probably judged by distinguishing the paper quality. The quality of paper across the market will not vary too much.

3) Selection of carton thickness Customized cartons are classified according to corrugated type

The thickness of a carton generally has three layers, five layers, seven layers, and nine layers. Approximate thickness of the third layer: is about 0.3mm, the thickness of the fifth layer: is about 0.7mm, the thickness of the seventh layer: is about 0.9mm, the third layer is also called the single pit, and the fifth layer is called the double pit. The thickness of reinforced and hardened cartons is the same, but the hardness is different.

4) The problem of custom printing of cartons

The larger the printing area, the more expensive it is. Of course, it also depends on the number of colors. Once the carton is printed, it cannot be modified, so it is necessary to confirm the printing content with the carton manufacturer several times. Some small mistakes can be covered with self-adhesive stickers or warm water stickers of the same color as the carton, but they are not beautiful enough. Try to provide the most accurate printing information, and supervise the carton manufacturers to print in strict accordance with the requirements.

5) Carton customized sample box

If the cooperation intention with the carton manufacturer is clear, and a consensus is reached on the paper quality and cooperation method of the quotation, the carton manufacturer can be required to provide a customized sample box. Carton samples are generally not printed, and the paper quality, size, and process quality are mainly determined.

6) The MOQ of customized cartons

Carton custom-made carton factory has a minimum order quantity problem. The minimum order quantity is 500 pieces. Different carton factories have different orders. It is recommended to make more cartons at a time.

7) Customized carton color

The color of all carton boards cannot be 100% the same as the previous color. If you have particularly high color requirements, you must communicate with the carton manufacturer.

8) Special Tips

The hardness of custom-made cartons: As long as it rains or is continuously exposed to moisture, even the original hard cartons will soften (the same is true for new orders).

7. Conclusion

This is the end of today’s “carton manufacturing” introduction, I hope it will be helpful to you, if necessary, please contact us to learn more.

Leave A Comment