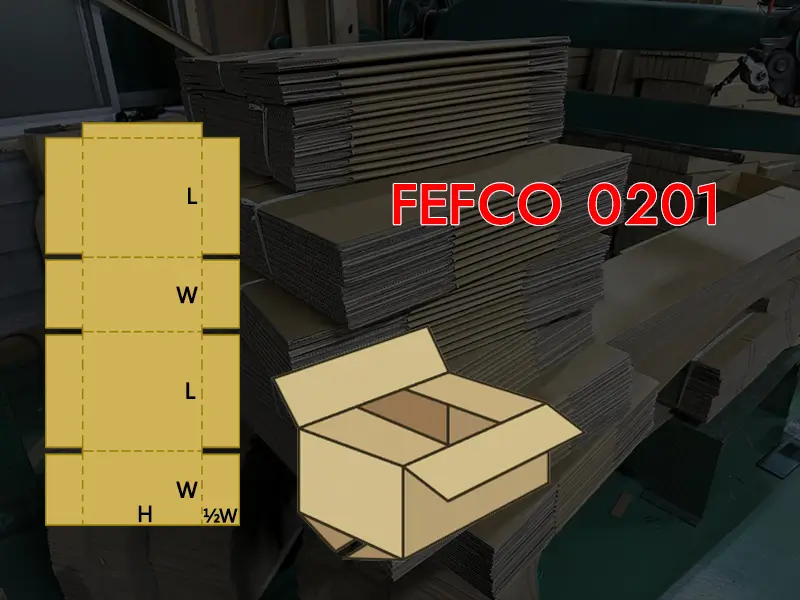

The FEFCO 0201 box type, internationally recognized as the Standard Regular Slotted Container (RSC), is the most common and widely used corrugated box style in the world. The designation comes from the FEFCO (European Federation of Corrugated Board Manufacturers) code system, a standardized classification that is universally adopted in the packaging industry. In China, this style is commonly known as a “对口箱”, which refers to its key feature: the top and bottom flaps are parallel and open towards each other in the same manner. Its simple, robust, and highly efficient design makes it the default choice for countless shipping, storage, and retail applications. Let’s see how to produce Fefco 0201 box type with Aopack corrugated box maker.

What is 0201 box type? Key Characteristics of the FEFCO 0201

The defining feature of the 0201 style is its flap structure. Both the outer and inner flaps are of the same length. When closed, the two major outer flaps meet perfectly at the center of the box, requiring tape or other sealing methods to secure them. The inner flaps, which are half the width of the box, meet opposite each other but do not touch in the center.

This design is prized for its:

Material Efficiency: The layout on the corrugated sheet minimizes waste, making it very cost-effective.

Strength and Stackability: It provides excellent protection for contents and, when sealed, creates a stable, stackable unit.

Ease of Use: It is simple to set up, pack, and seal.

Versatility: It is suitable for a vast range of products and can be easily displayed on shelves for quick access without the need for tools.

How is a FEFCO 0201 Box Made?

The traditional manufacturing process for a 0201 box involves several key steps:

1. Design and Platemaking: The dieline for the box is created, which is a flat diagram showing all the cut and fold lines. For printed boxes, a custom flexographic printing plate is also made.

2. Corrugated Board Production: Large rolls of paper (linerboard and medium) are fed into a corrugator to create the fluted corrugated sheet.

3. Flexo Printing, Slotting, and Die-Cutting: The large corrugated sheets are fed into a printer-slotter-die-cutter machine. This machine:

Prints: Applies any graphics or text using flexographic printing plates.

Scores: Creates the fold lines.

Slots & Die-cuts: Cuts the overall outline of the box and creates the slots that separate the flaps. For a standard 0201 style, a custom rotary die is often used to achieve this in a single step.

4. Folding and Gluing: The flat, die-cut sheets (called blanks) are then fed into a folder-gluer machine. This machine folds the blank along the score lines and applies glue to the minor flap, pressing it against the side panel to form a flat, rectangular box that is ready to be shipped flat to the customer, assembled, and filled.

Revolutionizing Production with the Aopack Corrugated Box Maker

While traditional manufacturing is effective for large runs, it relies on custom physical dies and plates, which are costly and time-consuming to change. This makes small batch or multi-size orders inefficient.

The Aopack corrugated box maker transforms this process. It is specifically designed to produce 0201-style boxes (and others) with unparalleled flexibility and speed, entirely without the need for traditional physical dies.

Die-Less Production: Aopack corrugated box maker machines use advanced digital cutting heads (e.g., router or laser) to score and cut the corrugated board precisely based on a digital file. This eliminates the cost and storage of countless dies.

Effortless Multi-Size Orders: Switching production from one box size to another is as simple as loading a new digital design file. There are no physical parts to change.

Lightning-Fast Changeover: This digital approach slashes changeover times dramatically. Transitioning from one order to another takes a mere 1 to 6 seconds, enabling truly on-demand, just-in-time production of custom-sized boxes in any quantity, from a single unit to thousands. This maximizes efficiency and minimizes waste for manufacturers handling diverse order portfolios.

Leave A Comment