Corrugated Box Maker Machine BM3000-HD Highlight

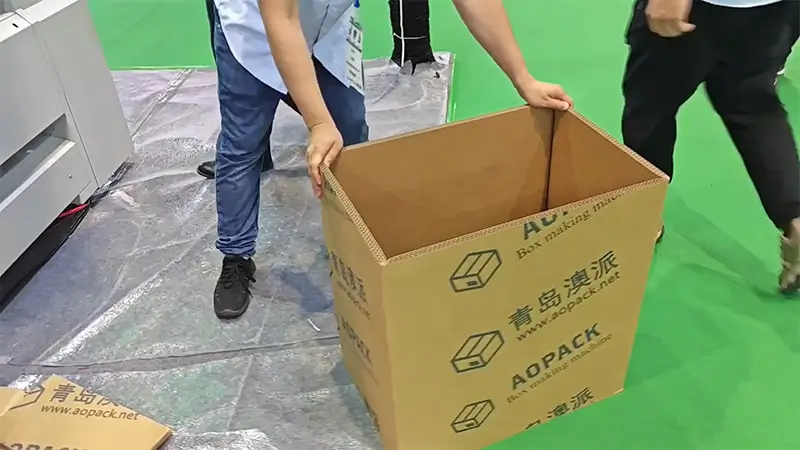

The Aopack BM3000-HD is a fully integrated heavy-duty box making machine designed to replace the traditional multi-machine approach. Its advanced engineering consolidates all production stages into a single, automated workflow, delivering unmatched efficiency and precision for heavy-duty corrugated packaging.

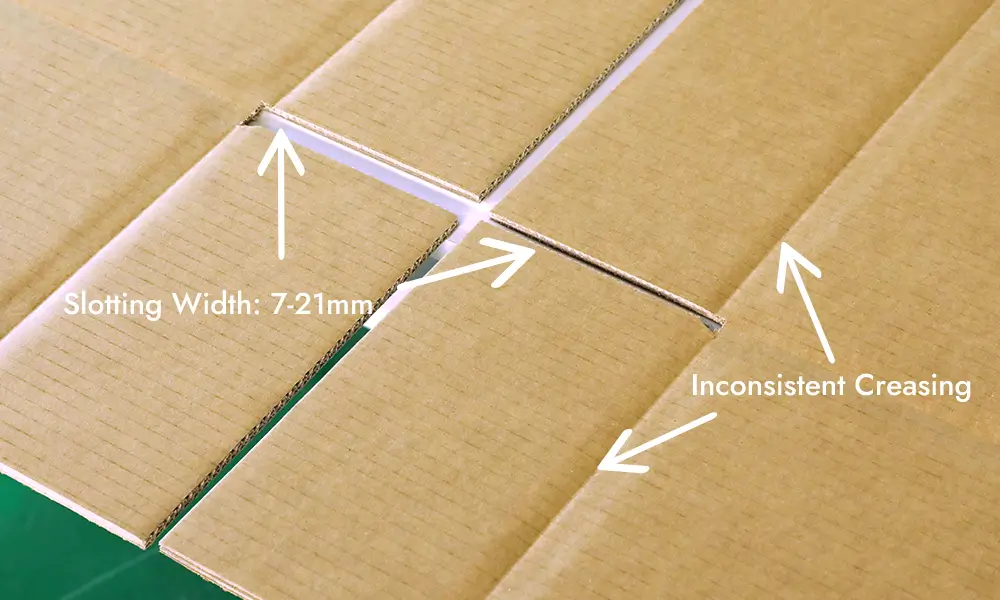

BM3000-HD is a revolutionary corrugated box machine , It can process cardboard from E flute to AAA flute, from 3 ply cardboard to 7 ply cardboard. Max. cardboard width is 3000mm and length is no limit. 7-21mm slotting width, glue flap crush function, auto knife sharpener, and inconsistent creasing available. 1-6s quick order changeover time, best solution for low to medium volume box production.

Versatile and Advanced Boxmaking Solution

BM3000-HD Heavy Duty Corrugated Box Maker Major Functions

Box Maker Machine BM3000-HD Optional Functions

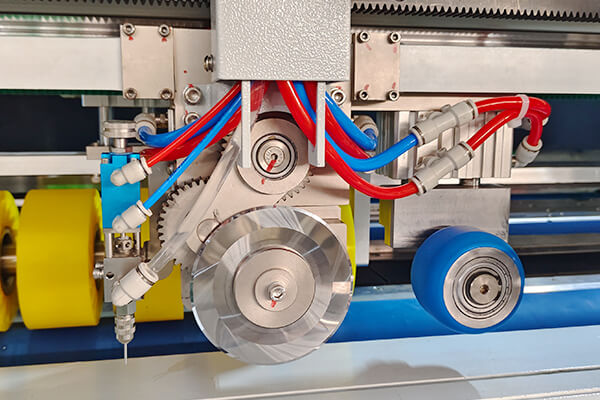

Vibrating Knife

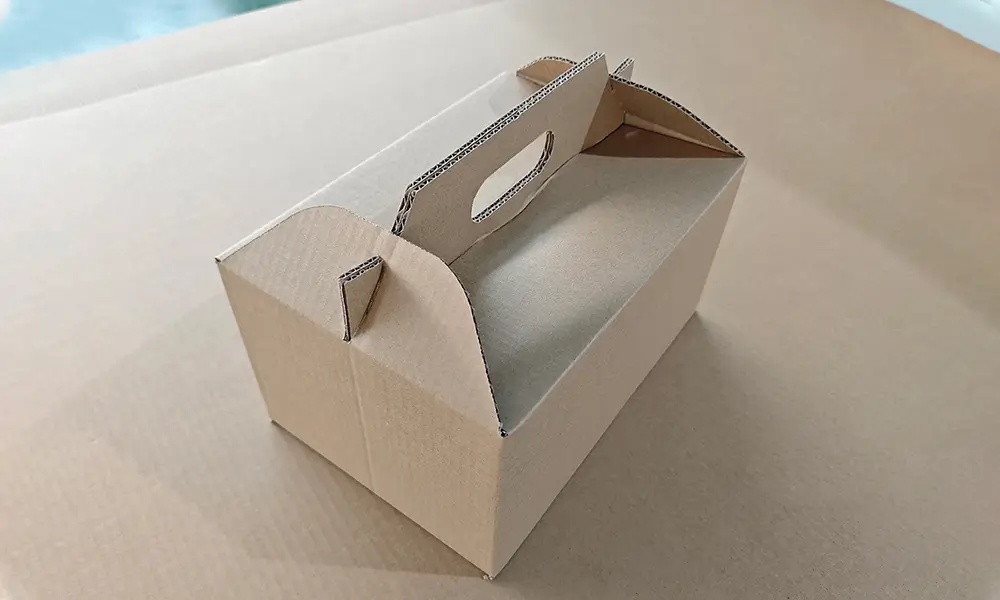

Available to cut round holes, rectangles, slashes, curves, and other Irregular shapes, No mold needed.

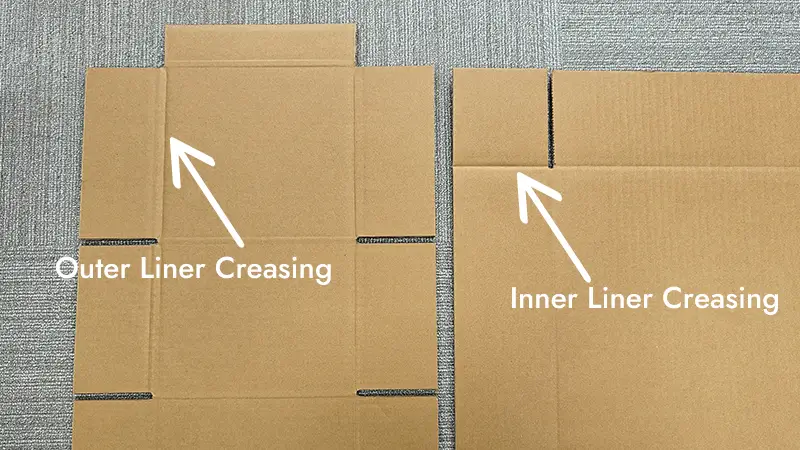

Male & Female Double-sided Creasing

Outer and inner liner double-sided creasing, Carton flaps inward and outward folding without burst.

Inline Gluing

Auto application in precise location, high efficiency and versatility, no need additional gluing machine.

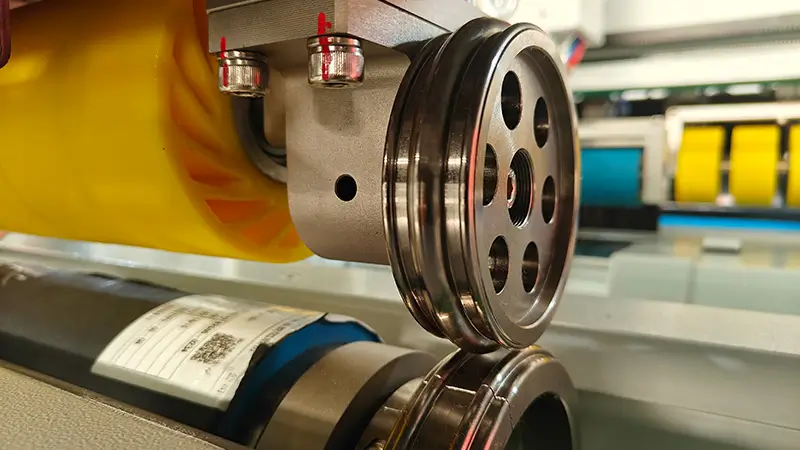

Flexo Printing

Single color flexo printing, Max.printing area 500*300mm(L*W)

Order Management System

Available to cut round holes, rectangles, slashes, curves, and other Irregular shapes, No mold needed.

Freestyle System

Free creation available, with unlimited box styles.

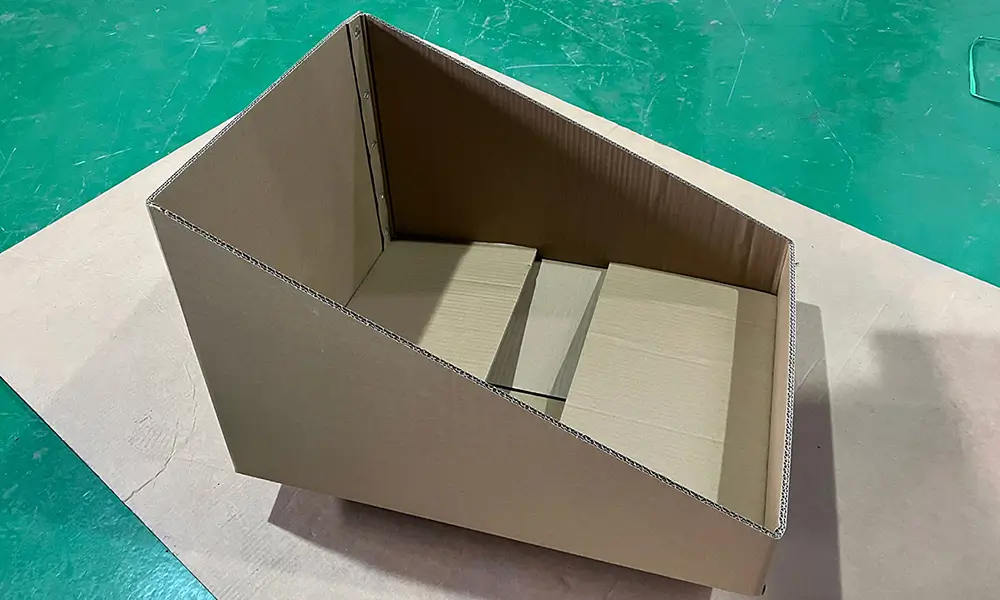

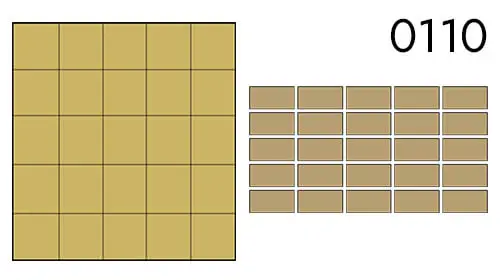

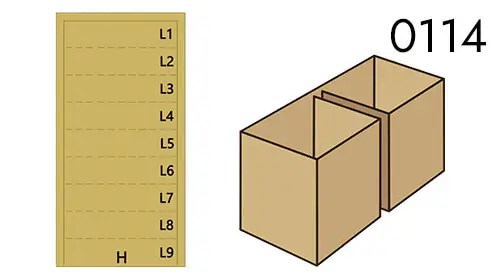

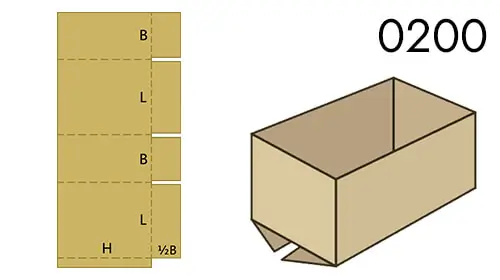

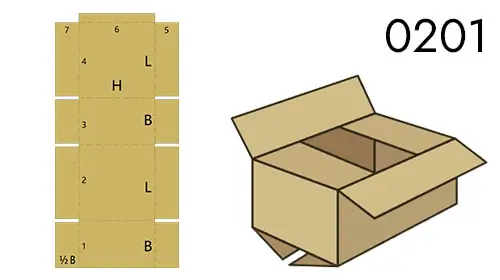

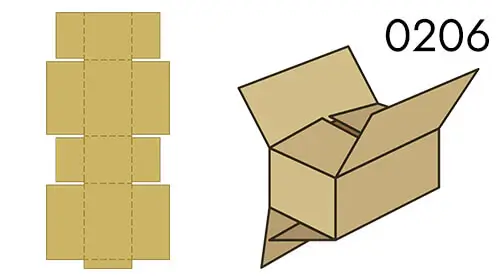

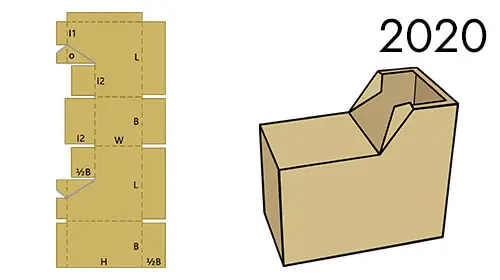

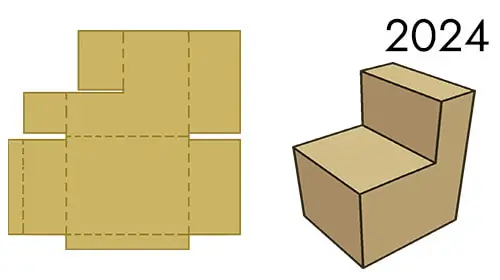

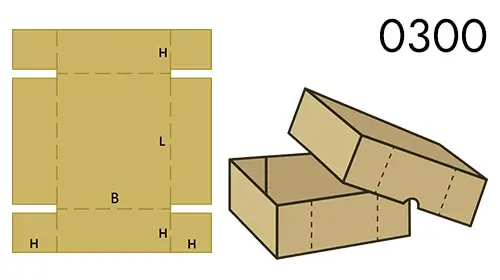

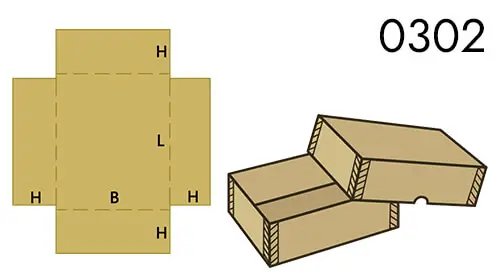

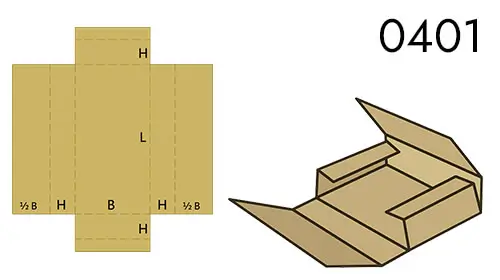

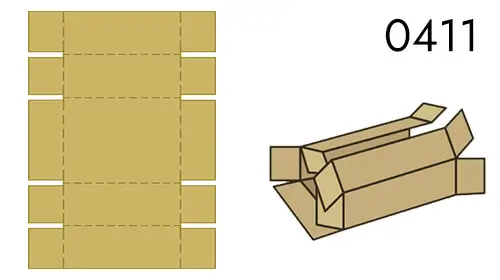

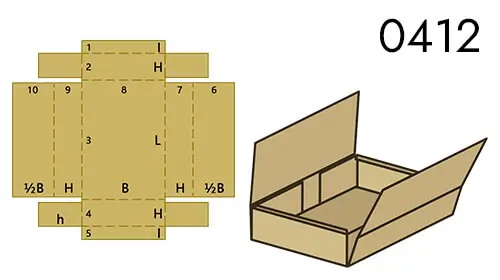

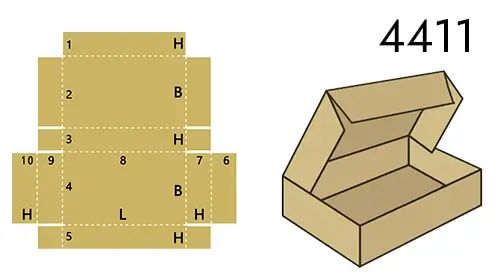

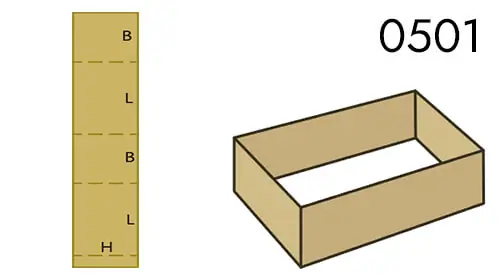

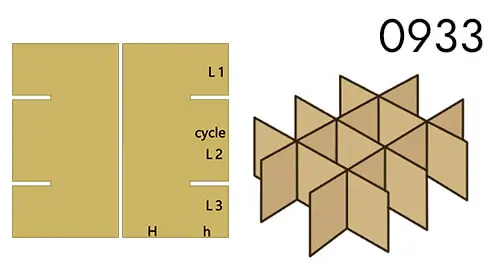

Box Making Machine – Box Styles List

Below are some featured box styles/types. For more box style lists, please download our brochure or contact us.

Heavy Duty Corrugated Box Maker Machine BM3000-HD Specification

| Cardboard Type | Single/Double/ Triple wall (AAA Heavy Duty Cardboard) | Cross Cutting Knife | 1 |

| Cardboard Thickness | 2-16mm | Power Supply | 380V±10%,Max 10kW, 50/60Hz |

| Cardboard Gram | ≤2400g/m² | Air Pressure | 0.6-0.7Mpa |

| Max. Board Size | 3000mm Width * Unlimited Length | Dimension | 3820(W)* 2060(L)* 1970(H)mm |

| Min. Board Size | 300mm Width * 660mm Length | Gross Weight | Appr. 4500kg |

| Production Capacity | Appr. 10-16pcs/minute. Depends on Box Size and Style. | Handle Hole on box sides | 150(L)*300(W)mm |

| Slotting Knife | 2pc * 500mm Length | Glue Flap Crush | √ |

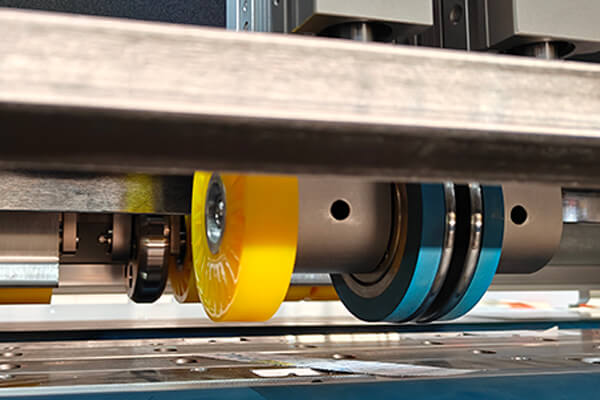

| Vertical Creasing Knife | 4 (With Knife Sharpening Function) | Air Consumption | 90L/min |

| Scoring / Creasing Wheel | 4+4 | Box Styles | 150+ |

| The above parameters are for reference only. And the final right of interpretation belongs to Aopack Ltd. | |||