Welcome to this article, which is an in-depth guide to folding carton machines, If you’re looking for any information about folding carton machines, you will find it right here. So keep reading to learn more.

1. What is a folding carton machine?

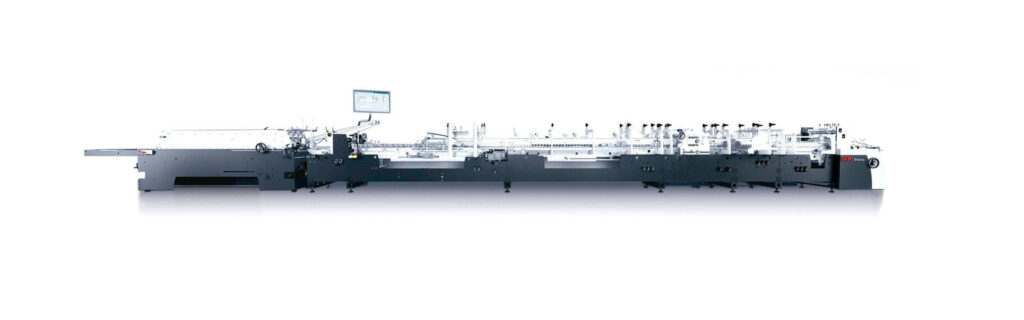

A folding carton machine, sometimes also known as a carton packing machine or packing machine, is a kind of packaging machinery. Its main purpose is to make cartons. The carton folding machine makes the carton stand up, fold, close, side sews, and finally seal.

2. What are the types of folding carton machines?

A folding carton machine can be a semi-automatic folding carton machine or an automatic folding carton machine. In addition, depending on the orientation of the carton, there are two main types of machines:

1) Horizontal folding carton machine

The horizontal folding carton machine includes product insertion from the side. The machine is capable of continuous or intermittent operation. These machines also have the option of automatic lateral loading. This machine has many uses in the food industry. Suitable for pizza, cake, rice, coffee, cereals, etc.

2) vertical folding carton machine

A vertical folding carton machine is the process of passing the carton through the machine in a vertical position. Depending on whether the machine is semi-automatic or automatic, the product is inserted manually or automatically. The product insertion process usually starts at the top. Some common applications include rice, dried pasta, etc.

3. How does the carton folding machine work?

First, the guide rails place the carton in the appropriate position, and then the pushing mechanism started by the push plate opens the carton. After that, the bottom of the carton is attached to suction cups (vacuum cups) pushed by a pneumatic system.

This is done from its back and front to ensure that the box reaches the loading area at a 90-degree Angle. In the loading part, the products are mechanically packed into cartons, but gently and accurately.

After loading, the chain conveyor guides the cartons to the folding area. In the folding phase, the goal of the carton worker is to fold the carton. This process is carried out simultaneously on the left and right sides of the rail by rotating motion.

The CAM is then attached to the motor to push the plate on both sides of the track for the actual folding procedure. The process then moves to the next critical stage, where the tongue of the carton is sealed in the front cover. After that, the push plate is used to initiate the push to bend the lid and create a firm lock.

The box loader then engages its label to manage the adhesive and closes any end of the carton to seal it completely. Finally, the system detects the accuracy of the carton.

It determines the quality of the packaging by carefully examining the structure of the carton, and then identifies the packaging directly into the carton chute and damaged packaging.

4. What are the advantages of using a folding carton machine?

Companies that use folding carton machines have a number of advantages:

- It helps improve efficiency.

- The alternative is time-consuming labor, including hand-crafting cartons and filling products, which can be quite an ordeal.

- There are horizontal and vertical types of packaging machines, so depending on the type of product, the right machine can handle either.

- A carton folding machine can help to fold cartons, erect cartons, and pack them into cartons.

- They also eventually repaired the carton before it was removed from the machine.

- The machine is capable of handling many types of cartons, such as small and medium-sized cartons, and is suitable for many different types of industries.

- Automatic carton folding machine is very beneficial to enterprises because it completely automates the packaging process.

- The use of the machine is cost-effective and makes the quality control process very simple, so the results maintain a high product standard.

- This is the best product management procedure.

- The use of carton packing machines enables the company to offer high standards of products at very low market prices.

- These machines also reduce the chance of error and help project management solutions, thus helping companies with smaller budgets.

5. What are the disadvantages of folding carton machines?

The following are some disadvantages of carton machines.

- It would be costly to build the whole machine at the initial stage because cartons are expensive to acquire.

- The cost of production is increased by the cost of hiring extra personnel.

- The machine is heavy and fragile, so there is no flexibility to move it after installation.

6. What is the application of a folding carton machine?

Industries that use folding carton machines include:

- Food and Beverage Industry

- Pharmaceutical and Cosmetic industries

- Food/Spices industry

- Toy Industry

- Clothing and Textiles

- Electronics Industry

- gardening

- Chemical Industries Inc

- the tobacco industry

- Sports Industry

7. How to choose a folding carton machine?

Here are three questions you should ask yourself when choosing the right wrapper for your packaging needs. These questions are essential for you to make the right purchase decision.

1) What types of products need packaging?

Usually, the type of product to be packed will directly affect your choice of folding carton machine. For example, if the product to be packed is granular and free-flowing, the most appropriate way to pack it into a carton is from above.

In this case, your selection of cartons will be limited to vertical cartons. However, the nature of the product may allow horizontal packaging into the carton.

In this case, your preferred carton machine should be a horizontal carton machine. Obviously, we first need to understand the business requirements and the nature of the product.

2) What is your budget?

After identifying the products to be boxed, make sure your procurement budget is the second phase of the project. Your economic ability will directly affect the type of carton machine you choose.

What will catch your attention when buying a carton machine is that most of the cartons available are horizontal. Horizontal folding carton machines offer more freedom and lower prices than vertical machines. However, if you plan to package capsules, particles or powders, and other products, you naturally need to choose a vertical folding carton machine.

3) Online packaging or offline packaging?

As a business, you know that offline packaging and online packaging for carton manufacturers in terms of speed and power requirements are not the same.

4) Online packaging

Online packaging refers to the packaging of products immediately after they come off the production line. Products should be packaged directly, so the speed of the origami machine should match the speed of production.

To determine the carton speed, simply calculate the maximum number of products produced per minute or hour and divide that number by the number of units per carton.

5) Off-line packaging

Off-line packaging means that you are packaging previously produced products. In this case, you don’t pay attention to production speed.

To determine the power and speed of a folding carton machine suitable for offline packaging, you should consider the following parameters. Consider the number of products you need to deliver on a daily, weekly, or monthly basis.

Be sure to compare only the actual working hours of carton workers, rather than simply dividing or multiplying every 8 working hours of the day.

Use extreme care when estimating quantities and be as accurate as possible. This program is very important to the future of your company. Overestimating actual demand can lead to the purchase of more expensive and powerful machines that are actually unnecessary.

8. What are the advantages of a carton folding machine?

Here are some of the benefits of packing products in cartons:

1) Product protection and convenient transportation

Cartons protect the contents. Due to the regular shape of the carton, it can be used for bulk packaging of containers, trucks, and other ships, which is convenient for transportation.

2) Environmental protection

Recyclable carton packaging has the best recyclability compared to any other packaging material. Renewable – In most packaging designs, you cannot replace raw materials extracted from nature to make packaging. Nonetheless, you can sustainably break down wood fiber and return it to Earth.

3) Tamper-proof

In addition to protecting your products from interference and adulteration, carton packaging can also be used as tamper-proof items.

This includes high-resolution graphics, double-sided printing, and carton shapes, expanding its use as packaging. Other advantages of carton packaging include:

- Light-Weight – Provides convenient handling

- Compared with other available substitutes, cost-effective – prices low

- Easy to shape into any type of shape

- Simple operation

9. How many kinds of cartons can be folded?

Boxes can play an important role in creating a striking look for your products, and you can use thousands of designs and types to package items of any shape or size. Let’s take a look at some common types of boxes that pack products:

1) Folding carton

Folding cartons are the basic and most common type of box for packaging products. Cartons are mainly used for packing consumer goods. In addition to different shapes and colors, there are a variety of shapes and sizes. The main purpose of folding cartons is to provide protection and enable the marketing and transportation of retail products. These cartons are made of different raw materials.

2) Hard box

It’s an updated version of a folding carton. Cardboard boxes are sturdy and are mainly used for luxury goods and display purposes. They offer additional protection in addition to high-end finishes.

3) Shoulder box

The shoulder box has a rigid cover, the base does not meet, and the middle part is called the shoulder box. You can use the shoulders to create features by applying a contrasting color to the bottom and top of the box.

4) Folding box

Foldable boxes are another type of box that can be used for product marketing. The box helps save on shipping costs and storage space and offers a wide range of design options to make your project really stand out.

5) Corrugated boxes

Corrugated boxes were traditionally used for external packaging by gluing together a pair of curved fluted pads, although it is now becoming more common among small companies. You can make them in almost any shape and size, and they are relatively cheap to produce.

6) Regular slotted container

A standard box used by packaging departments in which all creases from groove to edge are of similar length. Traditional slotted containers are ideal for transporting small personal products. They don’t have much room for customization other than changing the exterior design and printing, although sometimes less is more.

7) Half-slotted container

It is the same as a regular slotted container. However, this box type has an open side that is perfect for sliding pre-boxed merchandise. Roll end roll edge degumming box is formed by simple folding. This type of box is suitable for transporting retail products. The roll-top box is simple, but it tells a story about the brand that is straightforward and memorable.

8) Complete overlap

These types of boxes feature an external clamshell covering the entire width of the box, which helps to enhance their toughness and elasticity. They are a practical option for shipping products, and you can enhance them with amazing print designs.

9) Telescope box

A telescopic box consisting of two completely separate parts; A lid and a base. They are known for packaging high-end products such as technology, Apple’s iPhone packaging is a very popular example.

10) sliding box

Another type of box consists of two different parts. This type of box has an inner box and a sleeve.

11) Postboxes

Post boxes are designed for packing small items. They are designed for convenient mailbox and letterbox delivery.

12) Ready-made shelf boxes

Shelf preparation boxes are designed for retail shelves and store display items. You can design them to showcase your products and make them stand out to customers.

13) Custom-made boxes

The boxes are versatile and you can make them into almost any shape and size you want. Creating an exclusive custom box for your merchandise is the perfect way to create a memorable experience based on your customers.

10. What are the key components of the carton folding machine?

A folding carton machine is an equipment unit composed of mechanical, pneumatic, electrical, and light components. These components are connected in this way to generate, convert and efficiently use the mechanical energy generated by the system to form the packaging carton. The following is a list of key components of a folding carton machine:

- Control Panel

- Motors and electrical panels

- Conveyor, guide rail, roller, and carton chute

- Pneumatic system and carton packing tools

- Inkjet printers

- Lubrication system

- Security Systems

11. Can a folding carton machine be used in combination with other packaging equipment?

There is no doubt that the carton folding machine combines exceptional flexibility and optimized performance in a very compact design, which is perfectly suited for your operation. It allows integration with upstream packaging equipment to ensure seamless product manufacturing.

12. What is the difference between a semi-automatic folding carton machine and an automatic folding carton machine?

There is some difference between them below:

- Semi-automatic Carton Folding Machine for semi-automatic carton folding machines, whether horizontal or vertical, the operator must manually insert the product into the machine. Because there is no automatic feeding, the machine is easy to operate, but the production speed and output are significantly reduced. In addition, it requires multiple operators to be present.

- The automatic Carton Folding Machine is a more complex device that does not require much manual assistance in operation. The automatic carton machine has the ability to check the integrity of the carton to ensure that its quality is correct.

- All operations of the automatic folding carton machines depend on the digital control unit. The computer control unit runs, controls, and regulates all operations of the carton with minimal manual assistance.

13. How does the horizontal folding carton machine compare with the vertical folding carton machine?

According to the position of the carton inserted into the machine, the folding carton machine is divided into vertical and horizontal two kinds.

1) Vertical box folding machine

In a vertical folding carton machine, you can feed the carton vertically into the carton machine and pack items manually or automatically, in most cases from the top of the machine. Vertical folding carton machines are suitable for packaging “bare” products that can or should be transported by gravity and sold by volume or weight. Such products include dried pasta, rice, and so on.

2) Horizontal folding carton machine

With a horizontal folding carton machine, you can pack the product from the side of the carton. This type of carton folding machine can be operated in intermittent and continuous modes. It also has the option to automatically fill the product horizontally to the end of the carton and seal it by clamshell insertion or hot melt application. Horizontal folding carton machine is mainly used for food packaging, such as cereals, vacuum-packed coffee or rice, cakes, pizza, and so on.

14. How to modify the carton specification of the folding carton machine?

Modifying carton specifications will affect carton mold Settings and the main feed port. It is recommended to adjust the conveyor belt of the carton before sealing the carton manually. Continue to hold the top cover and place the carton in the middle of the conveyor belt.

Then, move the adjusting knob to adjust the middle plate to the position where the output belt can properly grip the carton. When making adjustments, be sure not to touch the internal creases. To accurately determine the width, loosen a few nuts on the carton conveyor and adjust the chain plate so that the carton width is equal.

You’ll also have to change your cardboard storage area. In this case, you will use an empty or flat cardboard box to change the entrance width by moving the front and back carton frames. Also, the length of the left and the right axis and the block axis must be identical to the blank box. The suction device should be in the same position as the cardboard box and can change the height of the box compressor. Another important aspect of adjustment is the length and height of the botanical rum relative to the box.

The side of the box should be in the middle of the box. Another parameter that requires modification is the location and batch number of the carton seal. You should adjust the location based on the box’s length and height. Also, it is necessary to change the spacing of the batch number so as to match the size of the paper. The front rail of the box shall also be the same as that of the box. The new box location and width will be used to change the location of the paper conveyor. Finally, the sensors are placed based on the new machine’s position.

15. How do you solve the paper folding machine?

There may be some problems when the packing machine is running. Let’s take a look at some of the issues and solutions. After a long period of high-speed running, the machine is not stable. solution:

Using the servo system, the folding machine can run smoothly. How to deal with the problem that the carton is not working because of blockage or leakage: Clean the oil pipe and change the corresponding oil pipe. Make a blank when the carton is filled: use photoelectric sensors (for example, multi-pulse technique) to detect and alert the faulty box. You need to stop the folding machine right away and fix the problem before it becomes more serious. To solve the problem that the paper box storage is not properly modified: Stop the paper folding machine, and correct the modification of the storage so that the paper box can be transported quickly and accurately. Non-Removable cardboard empty solution: Close the paper folding machine, remove the non-removable cardboard box and replace it with a better one.

16. Conclusion

This is an overview of the “Folding Carton Machine”. I hope the above information will be helpful to you.

Leave A Comment