We can extend the lifespan of the corrugated box making machine for at least 10 years if we do the maintenance regularly. The annual cost of the maintenance is only a few hundred dollars, with such a low cost can totally extend the lifespan of the equipment, it is a very cost-effective business. Now, Aopack would like to introduce the whole process of the maintenance of BM2508 Series.

1. BM2508 Series Box Making Machine Maintenance Process

The BM2508 series automatic corrugated box machine uses some transmission components, such as linear guide rail, ball spline, ball screw, and gear. In order to ensure the long-term stable and smooth operation of the equipment, these transmission parts need to be lubricated regularly. The driving parts of BM2508 series box manufacturing equipment move at low speed. According to the instructions in the technical manual of the part manufacturer, the lubrication effect can be achieved by using grease. The grease is selected as General Lithium Base grease No.2.

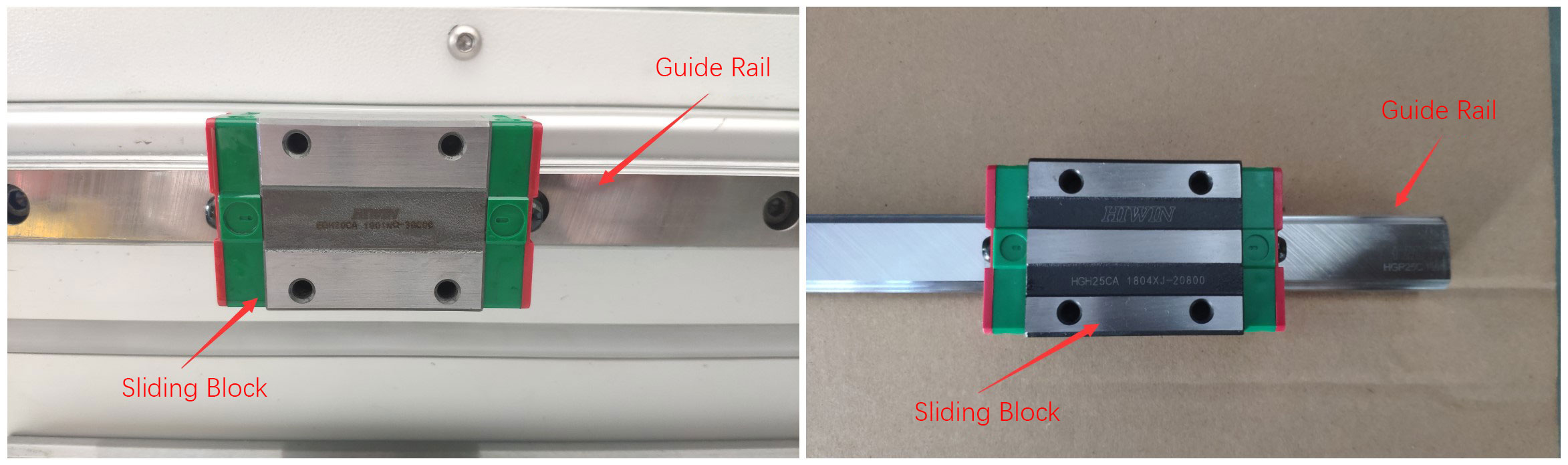

Part #1 linear guide rail lubrication

The linear guide has a higher rated load than linear bearing, and it can bear certain torque. It can achieve high-precision linear motion under high load. This is the reason why we choose the linear guide.

Its working principle can be understood as rolling guidance, the steel ball can move between the sliding block and the guide rail so that the load platform along the guide rail can move easily with high precision. Besides, the friction coefficient is reduced to the ordinary traditional sliding guidance of 1/50, can easily get a high positioning accuracy.

The linear guide has the following advantages:

- High positioning accuracy;

- Low friction;

- Stable operation

- Able to bear a load of up and down at the same time

It is required to add lubricant oil to guide rail and sliding block. According to the guidance of the linear guide rail manufacturer, you should add lubricating grease every 100km or every 3 to 6 months. Special lubricating grease filling port is provided on the sliding block. Different types of linear guide sliders need to be filled with different amounts of lubricating oil. According to the movement frequency and the sliders in different positions, there are also differences in the cycle of adding lubricating grease.

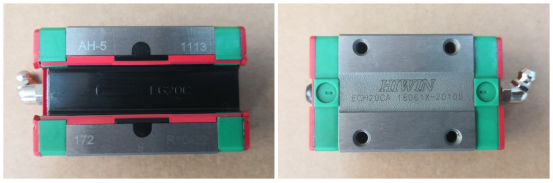

There are two sliders in our BM2508 series box making machine, EG20CA, and HGH25CA. The difference between the two models is in size and load. The sliding block and the linear guide rail are used together. The guide rail is fixed and the sliding block is sliding. The linear movement can be realized by using the two supporting devices.

- EG20CA : add 1.5 ~ 2.4 cm³ of grease each time.

- HGH25C: add2.8~4.6 cm³ of grease each time.

Note: The lubricating greas filling amount above is just the recommended value. In the actual operation, it may just need a little filling. Stop it immediately when there is a grease overflow.

Part #2 Ball Screw Lubrication

A ball screw is the most commonly used transmission element in tool and precision machinery. Its main function is to convert rotary motion into linear motion or to convert torque into axial repetitive force. It has the characteristics of high precision, reversibility and high efficiency.

Ball screw lubrication method is to add lubricating grease to the ball screw nut, according to the instructions of TBI transmission manufacturers, you should add lubricating greas in the first 3 months of the work and then add once a year.

Ball screw lubrication method is to add lubricating grease to the ball screw nut, according to the instructions of TBI transmission manufacturers, you should add lubricating greas in the first 3 months of the work and then add once a year.

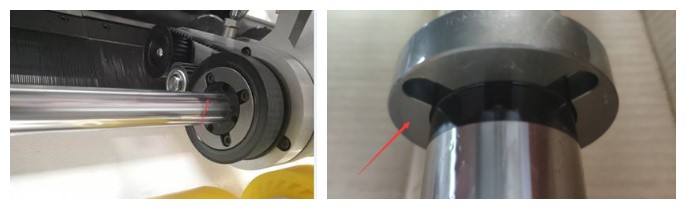

Part #3 Ball Spline Lubrication

Ball spline is a device for smooth rolling and torque transfer in precision ground rolling groove by using the ball installed in the outer barrel of spline shaft. Adopt unique contact point design, the contact point with a larger contact Angle (40 °).

In addition to high sensitivity, it can greatly improve the load capacity, suitable for a complex environment, such as large vibration impact load, high positioning accuracy requirements, high-speed performance environment. In this kind of environment, it can also play an effective role.

Ball spline lubrication is to add grease to the inside of the spline. Normally, when the running distance is up to 100km or after 6 ~ 12 months, the lubricating grease should be added in the groove of the ball spline shaft. The spline groove should be cleaned before the lubricating grease is added.

Part #4 Ball spline shaft transmission gear Lubrication

Ball spline shaft transmission gear is to transfer the power of the motor to the ball spline, driving the ball spline rotation.

You should coat the gears with grease for every two to three months.

2. Details of General Lithium Base grease No.2.

The maintenance of BM2508 series box making machine uses Kunlun universal lithium base grease No.2, and its parameters are as follows:

Description: This product is made by thickening refined mineral oil with hydroxy fatty acid lithium soap and adding various additives such as anti-oxygen and anti-rust. With excellent mechanical stability, oxidation stability and good water resistance, rust resistance, it can be used in the wet and contact with water mechanical parts.

Parameters:

Working cone penetration: 265 (0.1mm) -295 (0.1mm)

Appearance: light yellow or brown smooth cream

Corrosion (T3 copper, 100 ℃, 24 h) : copper no green or black

Drop point: less than 175 ℃

Corrosion resistance: less than grade 1

Oxidation stability: not greater than 0.07MP

If customers cannot find the same brand products, they can also find suitable products according to the product parameters. Aopack can also help to purchase from China, the price is about 40USD/ barrel (the actual price pls contact our sales), one barrel can support one year’s maintenance.

Leave A Comment